Aluminiferous ferritic stainless steels are extremely heat- and corrosion-resistant. Therefore, they are used in industry above all in areas subjected to high thermal stress and corrosion, like for example heat exchangers, catalytic converters and coolers (see Fig. 1).

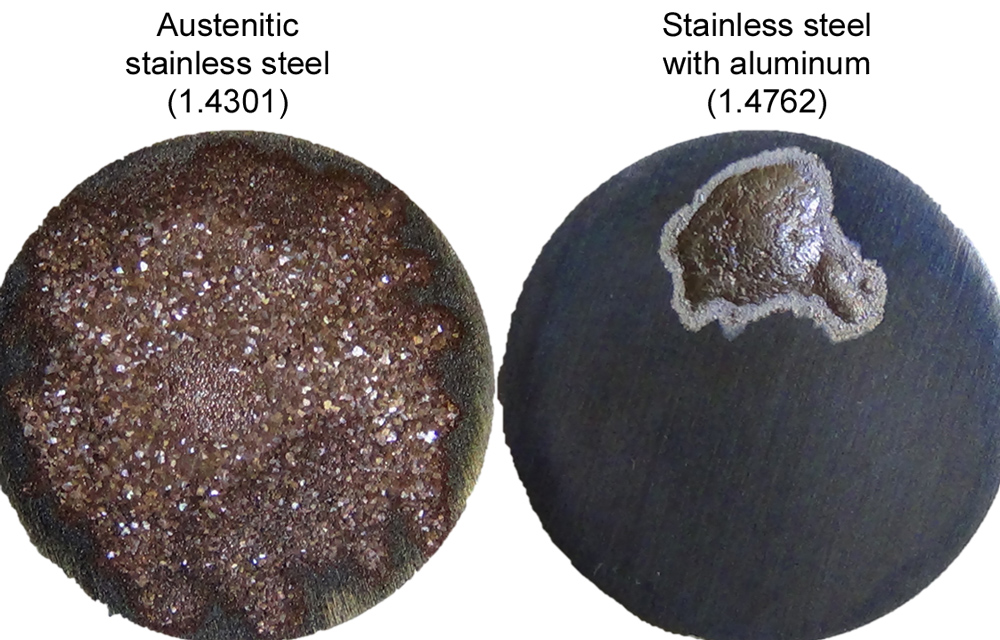

However, brazing of such components is complicated, because aluminiferous stainless steels passivate after thermal treatment. The passivation layer is a protection against heat and corrosion, but also prevents the solder from wetting the material surface. For this reason, aluminiferous stainless steels can only be brazed under high vacuum with practically no residual oxygen. This prevents the formation of undesired near-surface aluminium oxides.

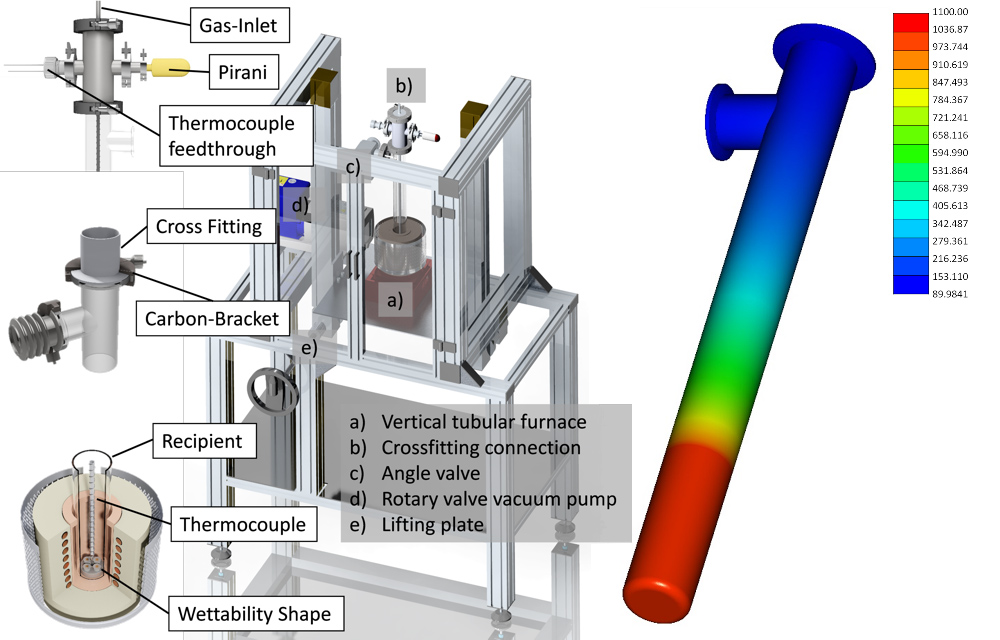

Researchers of the Division Joining and Surface Technology (FORTIS) at the Institute of Materials Science (IW) are currently developing a simpler and more efficient brazing process under low vacuum. They want to inhibit the undesired oxide layer by the use of silane, a silicon-hydrogen compound. The silicon reacts with the residual oxygen and forms a bond.