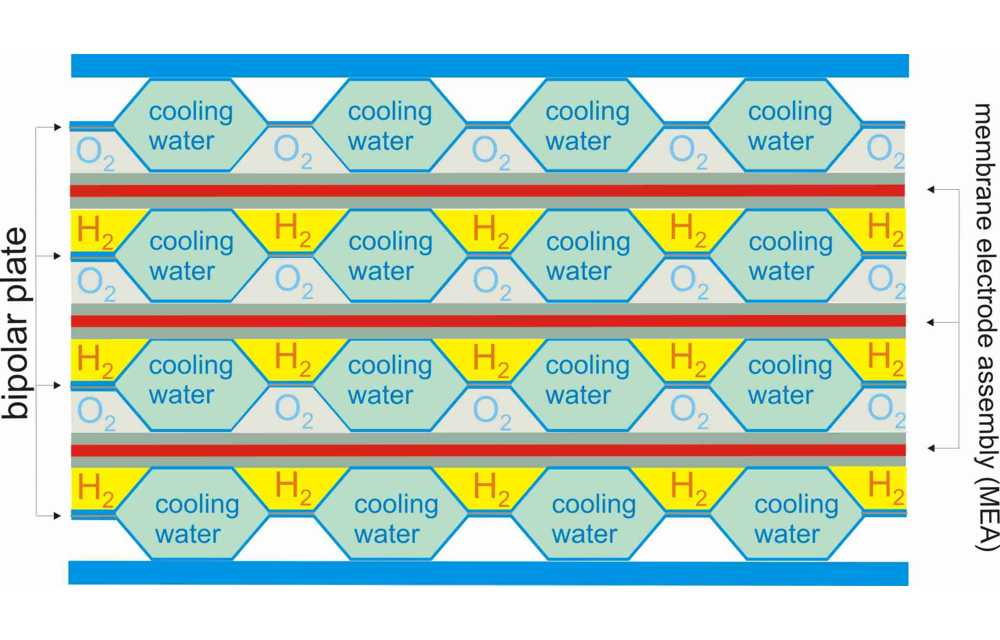

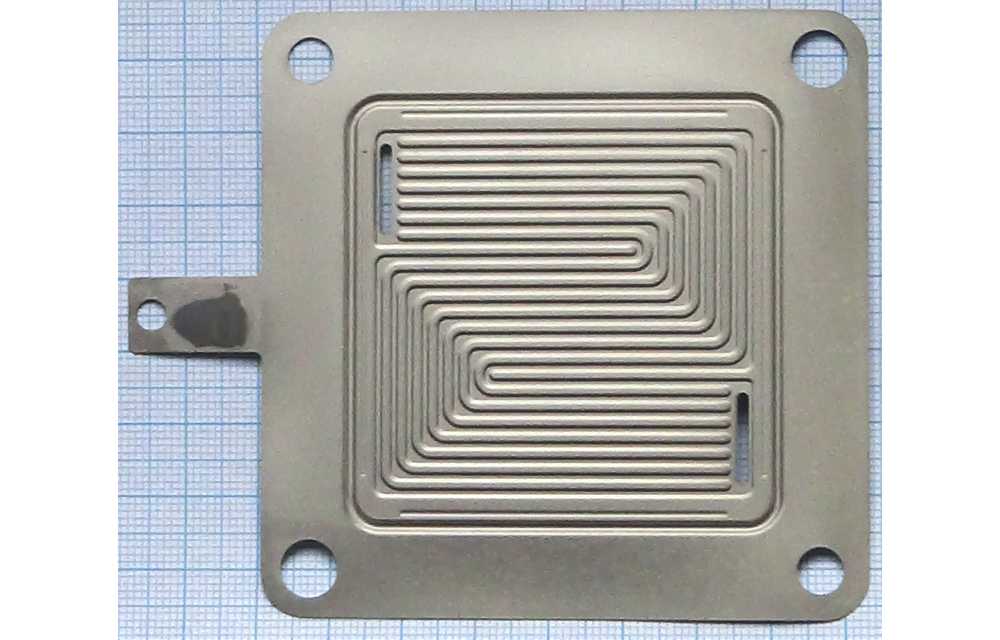

Fuel cells produce electricity from hydrogen and oxygen. One important component of fuel cells are so-called bipolar plates. Presently, their production is very expensive: Two stainless steel sheets are joined by means of laser welding, and then a conductive coating is applied, for example by vapour deposition of gold.

Researchers of the Institute of Materials Science (IW) in Hannover and the Institute of Materials Science and Engineering (IWW) in Chemnitz have found a more favourable solution. Instead of gold, they use chromium nitride layers. Their production is very easy: The plate surfaces are chromium-plated and then treated at high temperature with nitrogen in a shielding gas furnace, producing chromium nitride.

The special highlight: The process conditions in the furnace for the nitriding also allow for soldering up the two plate halves at the same time. This makes laser welding redundant, also shortening the manufacturing process and reducing cost. Moreover, the chromium nitride coating protects the base material against corrosion. Instead of stainless steel, the use of ordinary structural steel is sufficient.