Multi-step drill holes: Every car has plenty of them. For example, they are used to countersink screws in metal: The drill hole’s bottom part for the screw thread has to be narrow, whereas the top part has to be wider for countersinking the screw head.

Up to now, multi-step holes have been drilled by means of several standard drills used one after the other. In contrast, a customized step tool is able to drill holes in a single step – without changing the tool. However, the development of step tools is very complex.

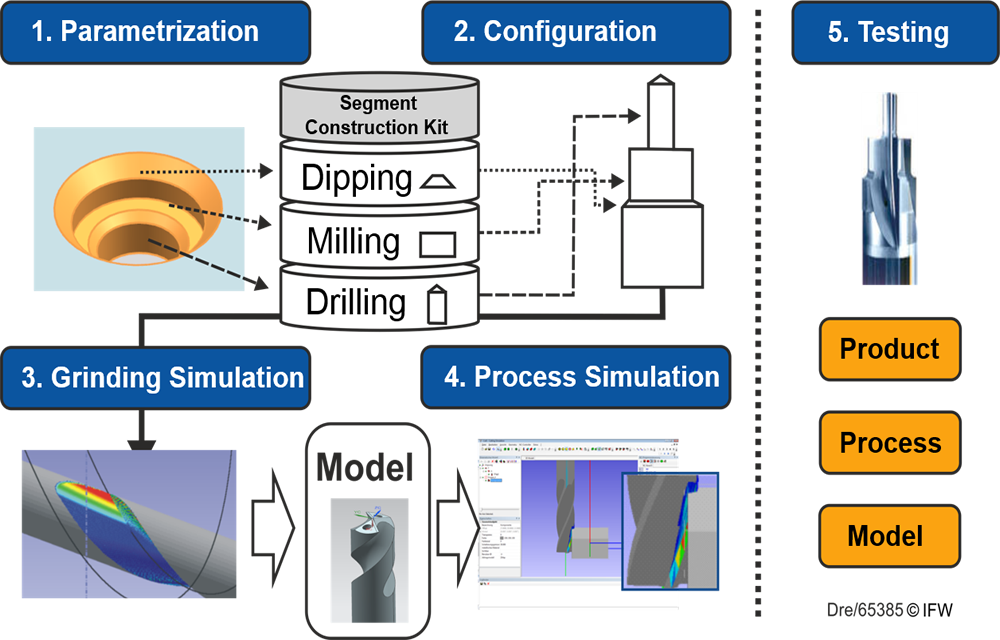

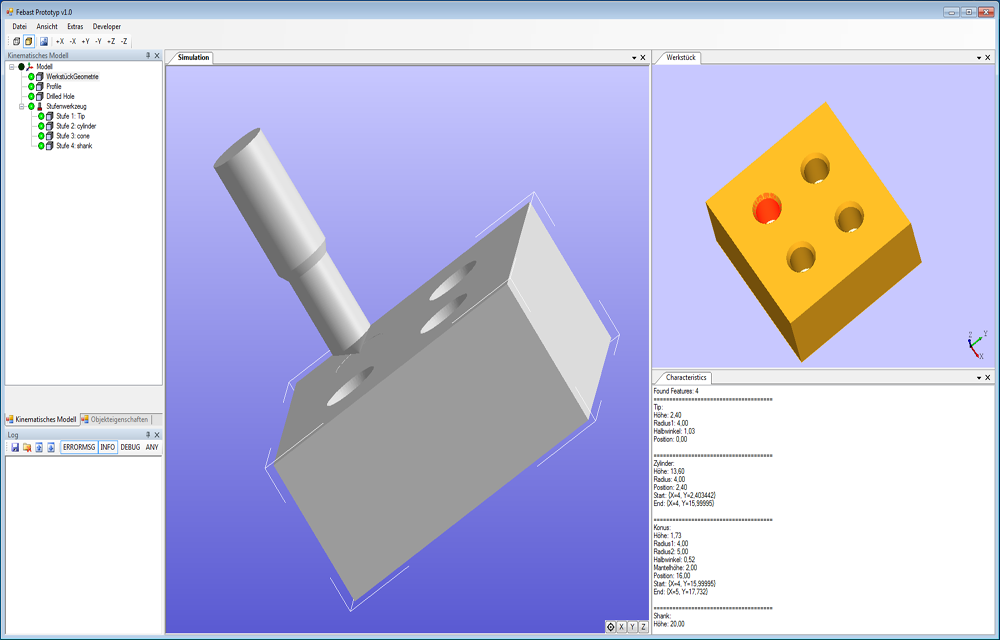

Researchers of the Institute of Production Engineering and Machine Tools (IFW) want to solve the problem: In the joint research project “FeBast“, they are developing together with two industrial companies a software program for an automated step tool design. With just a few mouse clicks, the design engineer can select from various standard elements and create new tool models.