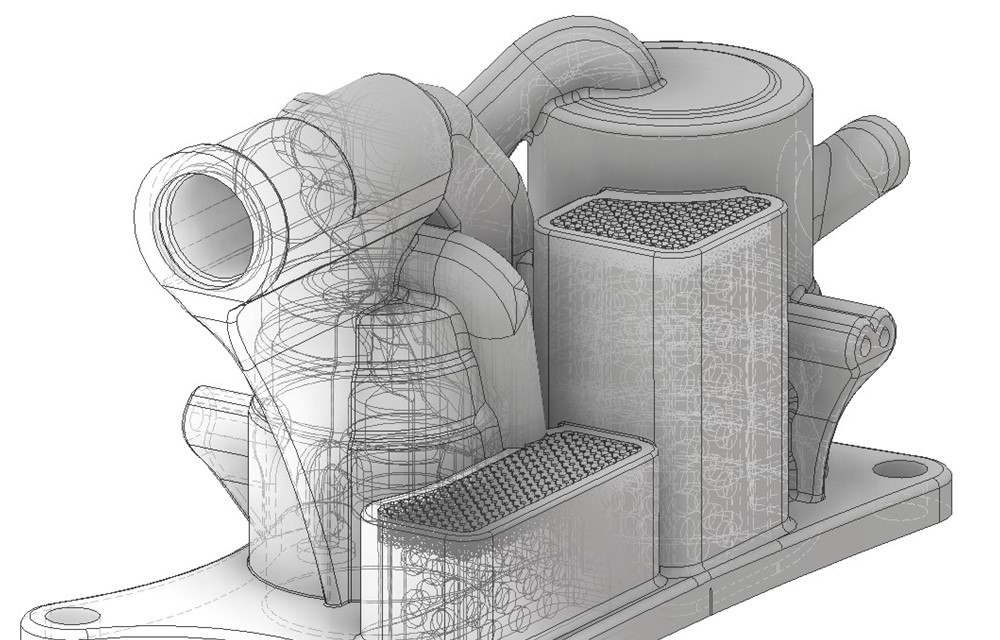

Compared to conventional manufacturing processes, additive manufacturing offers enormous potential for the design of parts. To fully exploit these degrees of freedom, however, the parts must be designed differently than before.

The workshop " Konstruktion für die Additive Fertigung", jointly organized by the Laser Zentrum Hannover e.V. (LZH) and the Institute of Product Development and Engineering Design (IPeG) of the Leibniz Universität Hannover, will take place at the LZH in Hannover on 26 September 2018.

The focus is on the following topics:

- – Specifications of parts and processes

- – Design and functional optimization of parts

- – Computer-aided simulation and physical validation for quality assurance

- – Integration of additive manufacturing processes in the process chain

- – Opportunities to increase the productivity

- – Development of new business models

Information on the program and registration at www.lzh.de/de/ws-konstruktion-fuer-die-additive-fertigung. The event is held in German language.