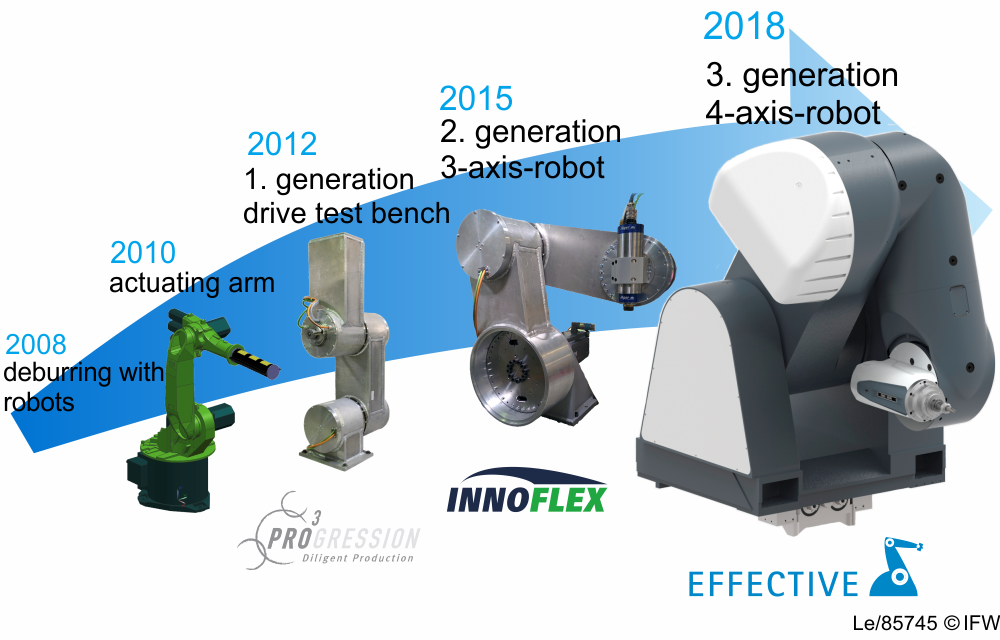

More and more industrial robots are employed in machining processes due to low acquisition costs and high flexibility, thus contributing to lower production costs. However, their low positioning accuracy and stiffness are still problematic.

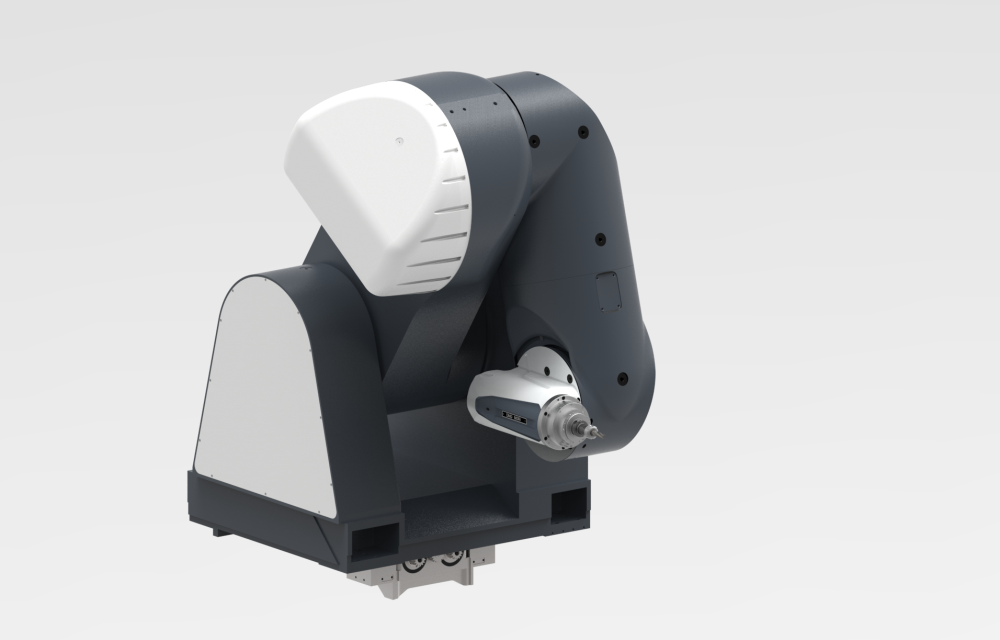

Within the scope of various research projects, IFW has been working on how to solve these problems. One problem is the deburring of components: Since existing industrial robots are not suitable for the machining of complex components due to their lack of accuracy and productivity, the researchers are developing measures to remedy these deficiencies. Besides the development of actuating arms, hybrid actuating systems and offline as well as online compensation, they have mainly taken constructive measures. After the initial setup of the first prototype, the launch of an entirely new machining robot is scheduled for the end of the year.