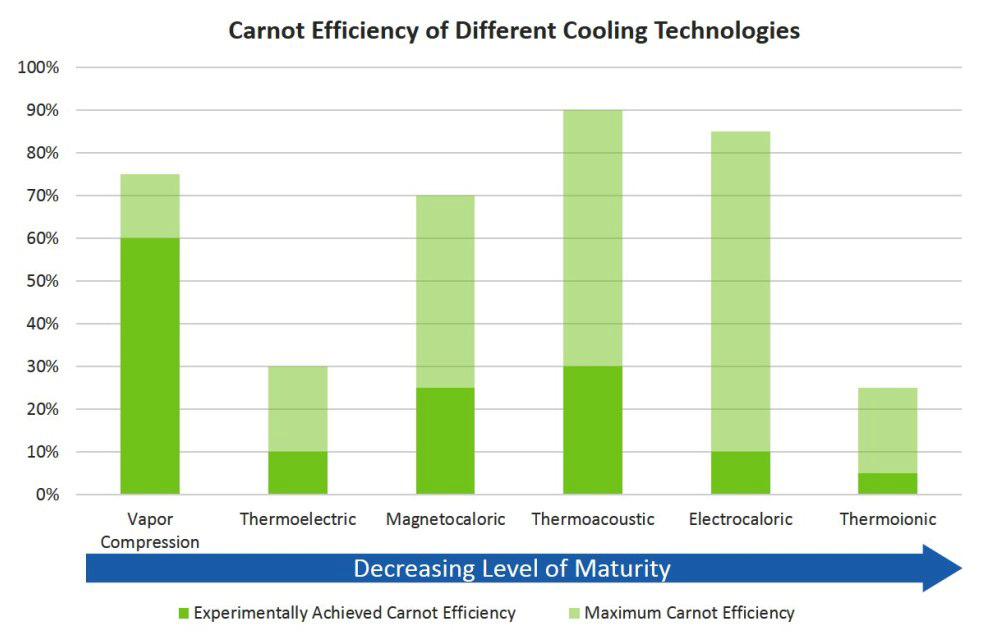

Cooling systems keep food and drugs fresh, cooled processors enable higher clock rates, and batteries in electric vehicles last longer at constant temperature. The drawback of cooling systems is the high energy consumption. For this reason, research is focused on the development of more efficient systems.

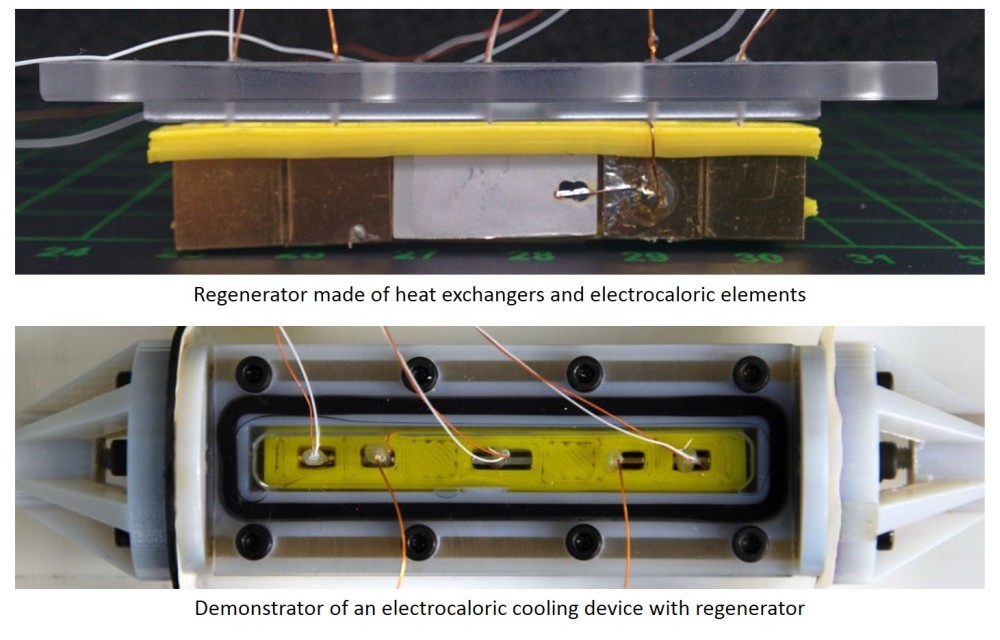

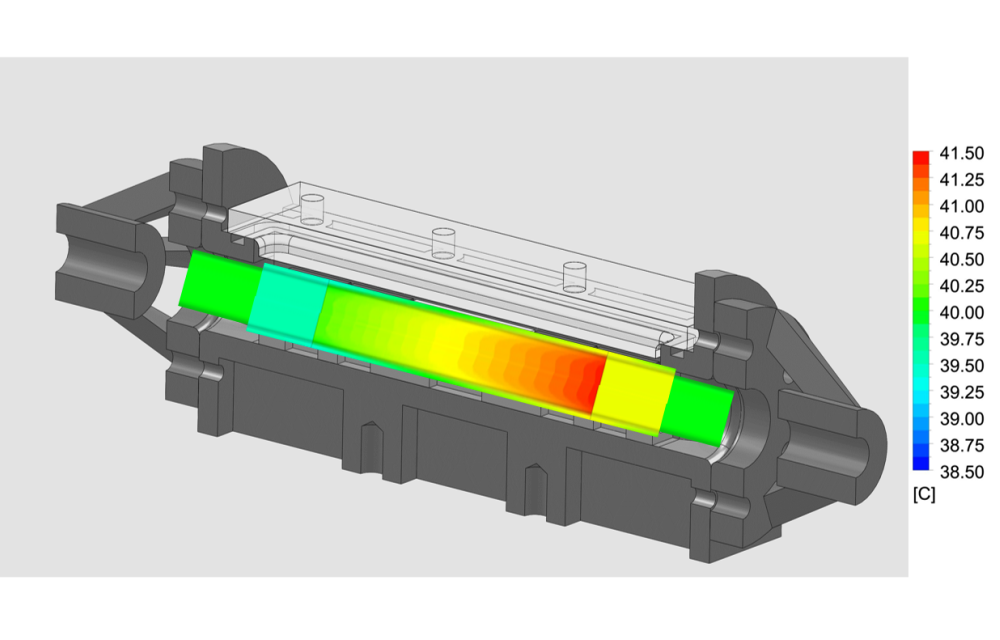

Within the scope of the DFG Priority Programme 1599 "Caloric Effects in Ferroic Materials: New Concepts for Cooling", the Institute of Assembly Technology (match) is working on electrocalorics as an innovative cooling technology. In the Subproject B7: "Methodological Development and Design of Electrocaloric Cooling Systems for Electric Vehicle Applications", match scientists are investigating on the optimum design of electrocaloric cooling systems for maximally efficient use in real applications – for example, in e-vehicles for battery cooling.

The influencing parameters are determined by simulations and lab demonstrators, being the basis for a universal development methodology and an application-oriented design. In this way, the first commercial electrocaloric cooling systems could be ready for use in about 10 to 15 years.