Lighter components and more efficient manufacturing technologies: These aims are in the focus of researchers of the Institut für Integrierte Produktion Hannover gGmbH (IPH), the Institute of Forming Technology and Machines (IFUM) and the Institute of Materials Science (IW).

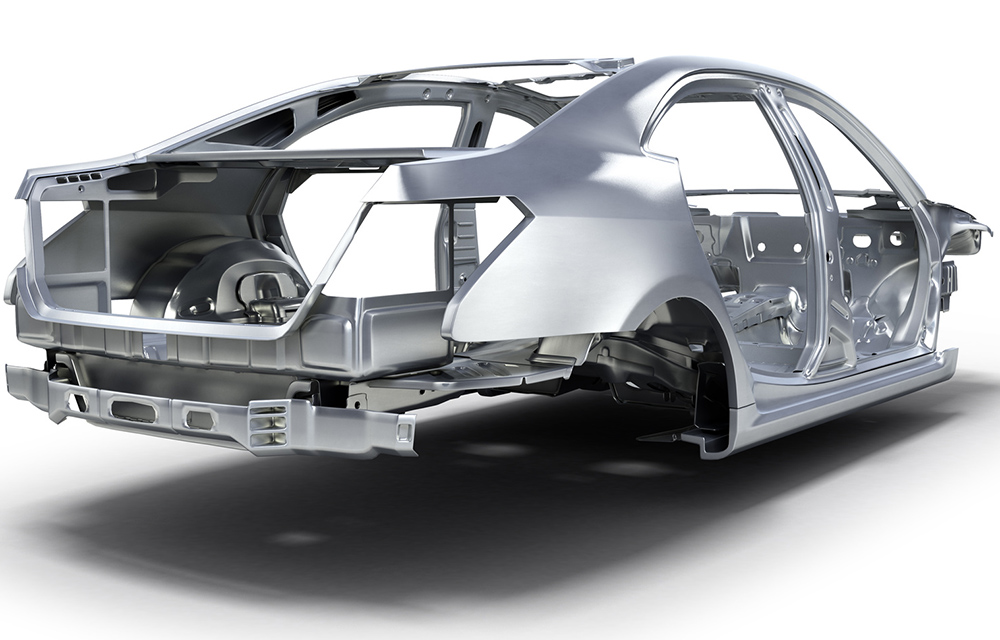

IPH researchers develop a novel lightweight design concept for car body construction. They investigate tailored hybrid tubes. Here, steel and aluminium are joined by laser brazing and soldering processes and then shaped by hydroforming.

Researchers at IFUM and IW work on a new realistic stress test for clinched components, the first test which considers thermal as well as mechanical stress. Another research topic at IFUM is to design a tool which allows forming and joining at the same time: The aim is to weld components already during the deep drawing process. Moreover, the researchers search for an alternative to welding: Upset bulging is a method to join sheets and tubes mechanically.

The research results will be presented at the EuroBLECH exhibition: www.euroblech.com/english