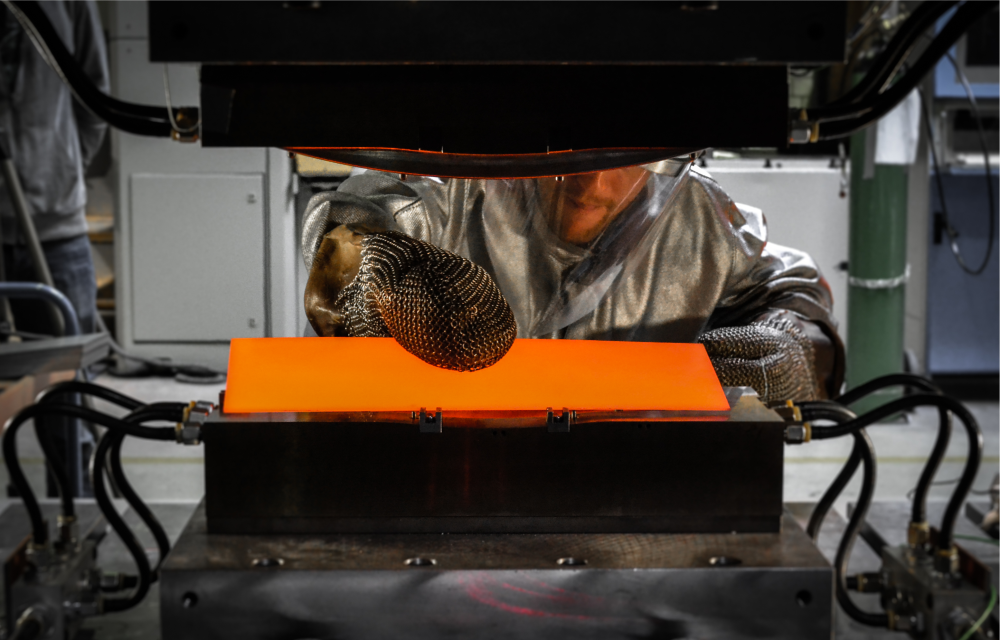

In automotive lightweight construction, hot stamping is a well-established method to produce high-strength safety-relevant component parts. Sheet steel is heated to 930°C forming temperature. The forming tool remains closed for some seconds to cool the component part down as fast as possible to approximately 150°C, thus increasing the strength considerably.

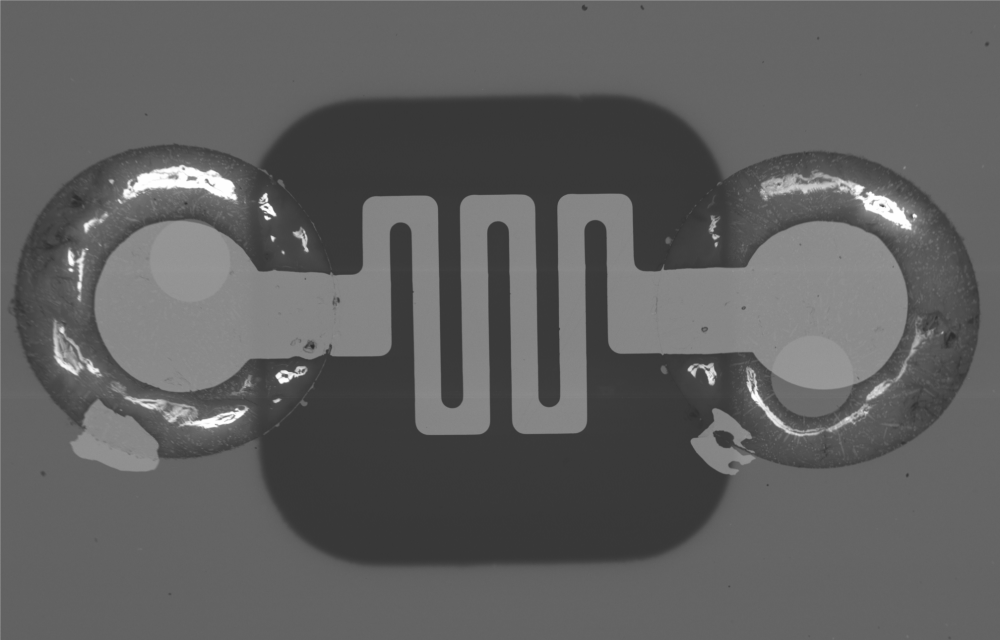

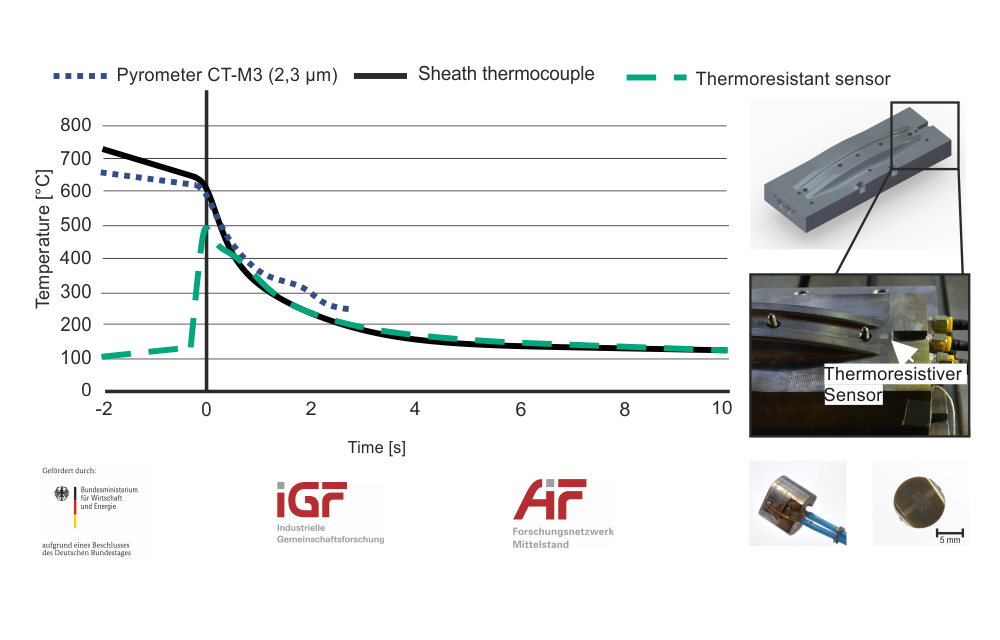

For temperature control, researchers of the Institute of Forming Technology and Machines (IFUM) and the Institute of Micro Production Technology (IMPT) developed sensor prototypes. Based on the thermoelectric and thermoresistant effect, they produced thin-film sensors in the range of fifty nanometres. At the same time, the researchers developed a concept for integrating the sensors into a forming tool.

In comparative measurements, the sensors proved high accuracy. They help manufacturers to improve the quality of hot-stamped parts and optimize the time when to withdraw the part from the tool, thus making the whole production process more efficient.