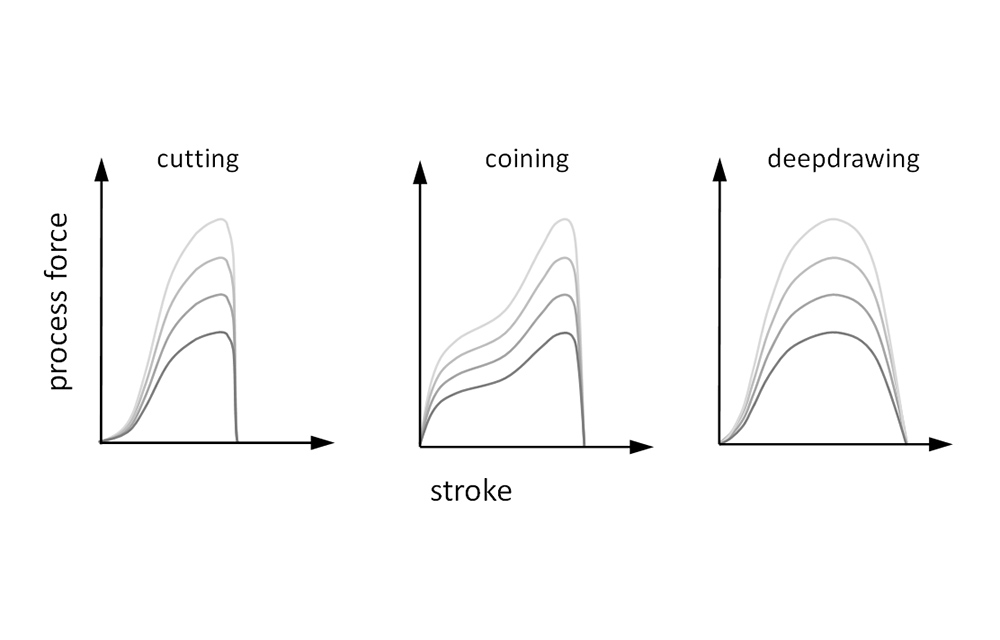

Presently, it is very complex and time-consuming to determine the efficiency of a forming press, requiring the use of test tools in order to model equivalent processes and measure the converted energy. However, efficiency varies with the forming process: Whereas the efficiency of a press can be high during deep drawing, it might be low during a coining process. Therefore, companies would have to develop several test tools to be able to determine the efficiency of a press.

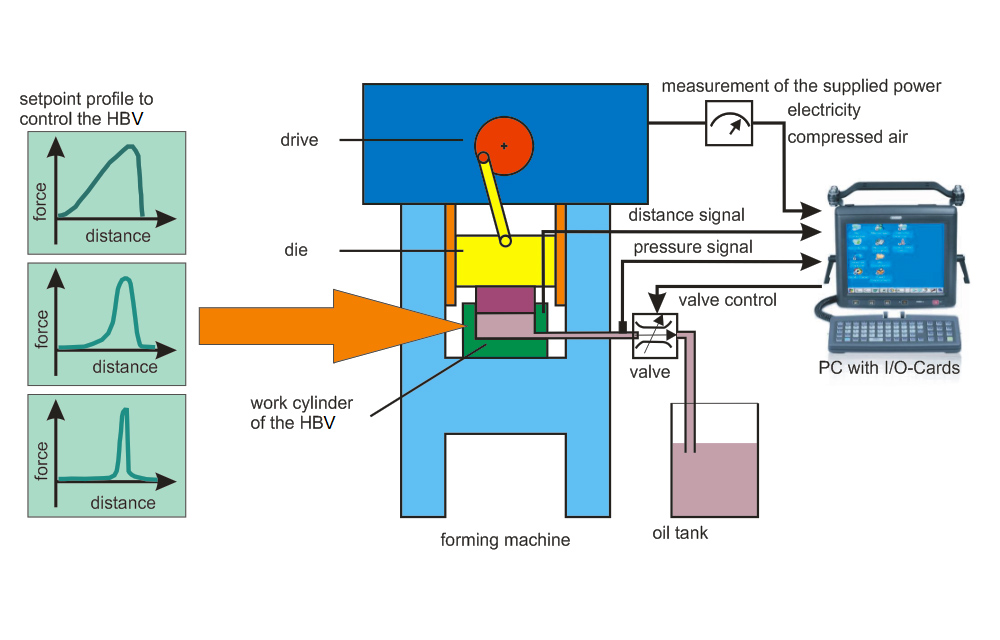

At the moment, researchers at the Institute of Forming Technology and Machines (IFUM) are about to develop a more efficient approach. They want to insert a hydraulic cylinder into the work space of a press (see Fig. 2), so that the descending die hits the piston rod of the cylinder. The process force, which counteracts the movement of the die, is constantly controlled by a valve. In this way, mapping of characteristic stroke-force diagrams for different processes like coining, deep drawing and cutting processes (see Fig. 3) is possible with just one device.