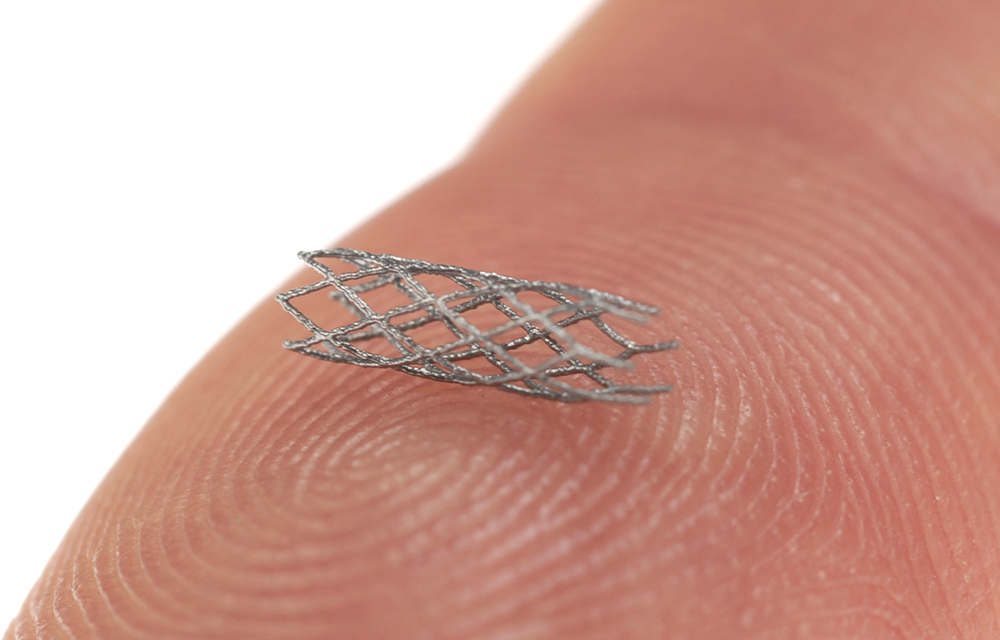

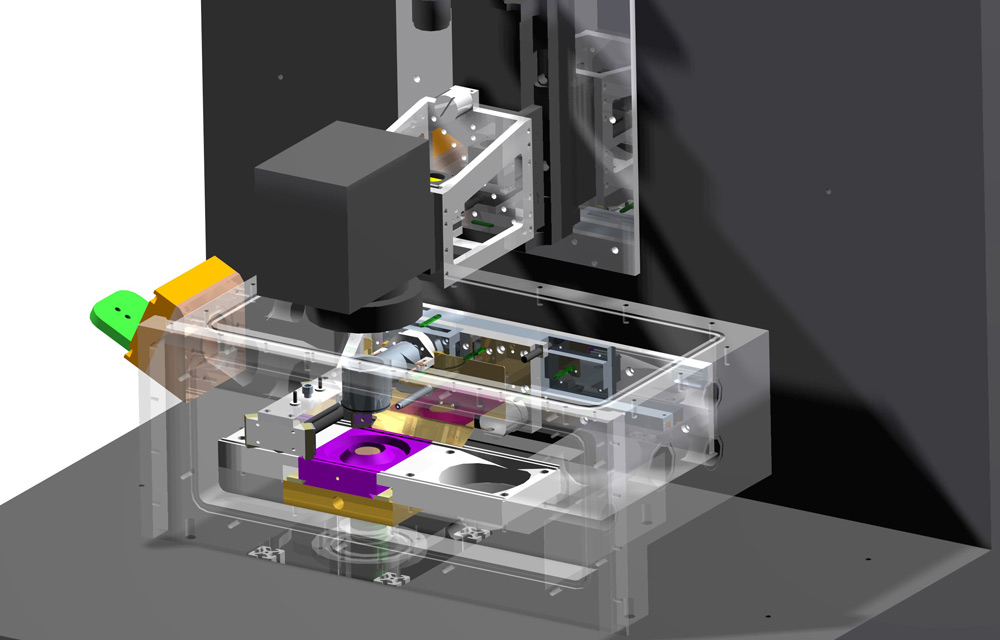

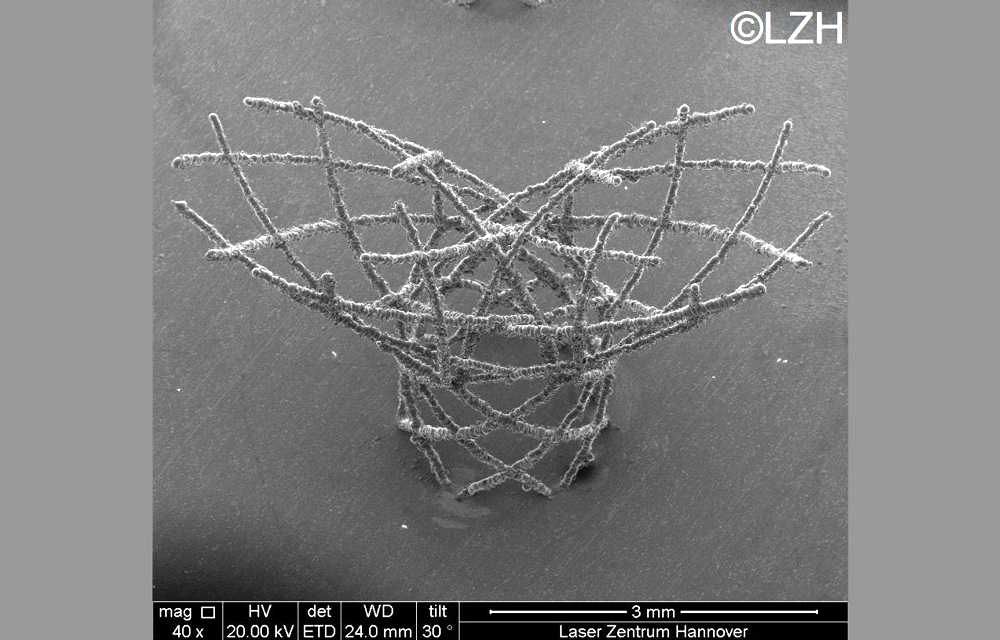

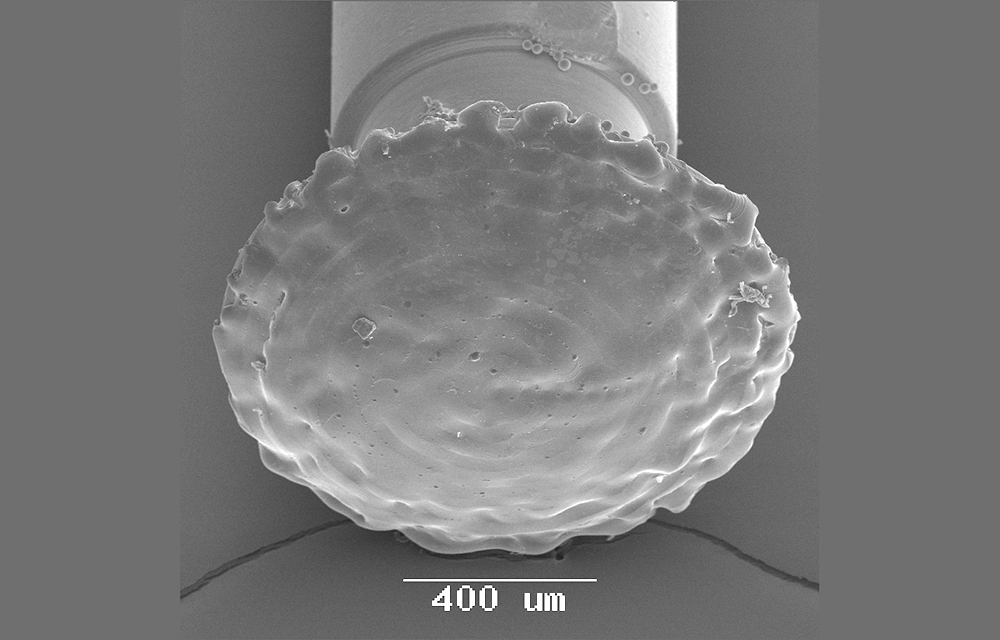

For this purpose, the scientists of the Surface Technology Group used a special 3-D printing method – the Selective Laser Micro-Melting (SLµM). By means of partly customized systems, they succeeded in coating electrodes for cardiac pacemakers with platinum, and manufactured three-dimensional lattice structures from NiTi and stent prototypes from stainless steel and NiTi.

SLµM makes it possible to adapt stents and implants individually to the patient’s requirements, and can open up new perspectives in the field of medical technology in the future.

The research works were carried out as a subproject of the joint project “REMEDIS” in cooperation with the Institute for Biomedical Engineering at the University of Rostock. REMEDIS was funded by the German Federal Ministry of Education and Research (BMBF).