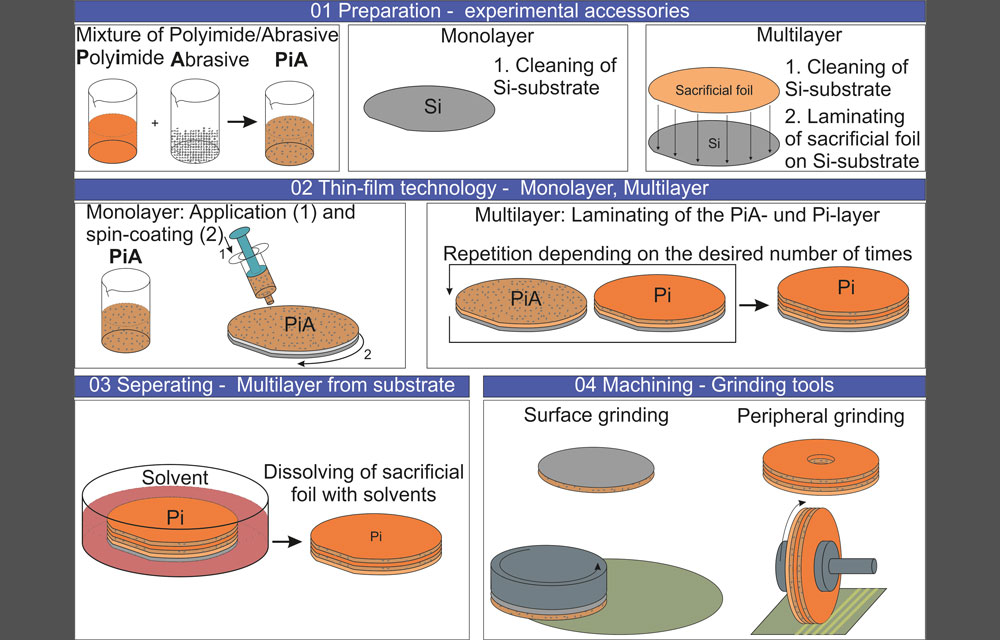

The Institute of Micro Production Technology (IMPT) and the Institute of Production Engineering and Machine Tools (IFW) are presently developing a novel process for the production of two types of grinding wheels for both surface grinding (ultra-precision machining) and peripheral grinding (micro structuring). As to peripheral grinding tools employed in micro structuring, the new manufacturing method makes time-consuming profiling processes during manufacturing and complex dressing processes during machining – associated with expensive tools – redundant. With respect to surface grinding tools for ultra-precision machining, labour-intensive conditioning processes become a thing of the past. During the production process, the researchers are also able to introduce abrasive grains in a controlled manner, thus allowing the creation of tailored structures.