Dr Marc-André Dittrich is researching the industrial production of the future at the Institut für Fertigungstechnik und Werkzeugmaschinen (IFW, Institute for Manufacturing Technology and Machine Tools). In the future, machine tools should be able to control themselves. Like cars, they should learn to drive autonomously. "We’re trying to think technology forward for the next 15 years," says Dittrich. With his research team on "Production Systems", which is 31 members strong, he plans projects ranging from basic research to market applications.

The fact that the Garbsen-born scientist now works in research is partly thanks to Timothy Gutowski, Professor at the Massachusetts Institute of Technology (MIT). After his bachelor’s degree in industrial engineering at Leibniz Universität Hannover, Dittrich moved to MIT via the IFW for a stay abroad. There Gutowski got him enthusiastic about science. "You have to think things through," the professor gave him as his motto.

After his studies, he began his research work at IFW in cooperation with Daimler AG. Two years later, he transferred to the IFW for his doctorate – and stayed. However, Dittrich hasn’t lost contact with the MIT. He has just published another joint research paper with Gutowski.

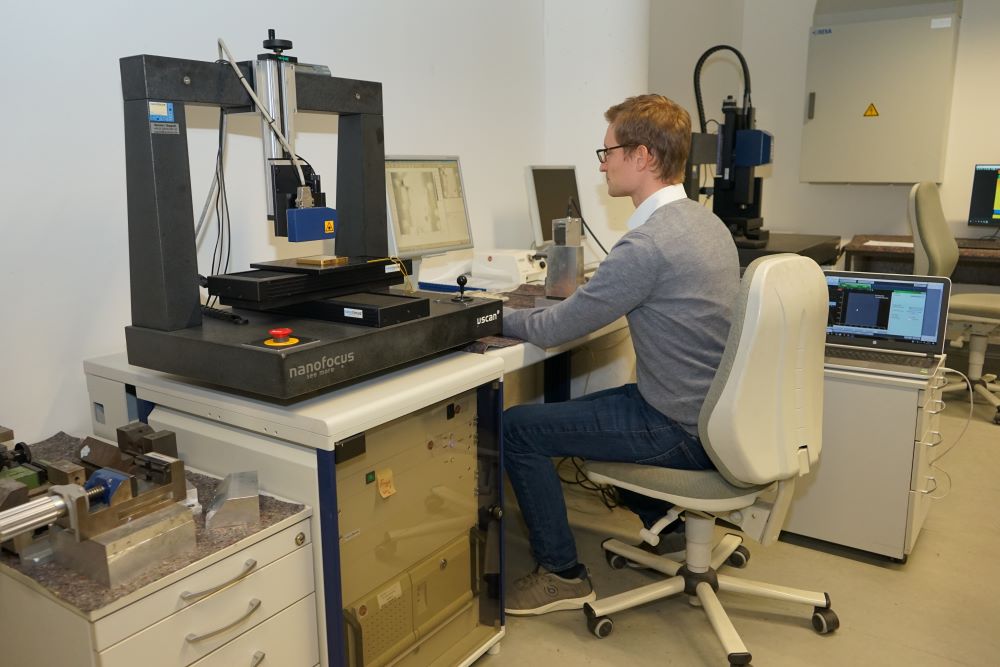

Within PhoenixD, his interdisciplinary Task Group F2 – Expert Systems for Quality Control is working on two tasks. On the one hand, they are testing a new manufacturing process to be able to produce reflective, high-gloss surfaces in one step. In future, these are to be used in special high-performance optics and moulding tools.

Secondly, they are researching new methods for measuring the production quality of components. After only three quarters of a year, they have applied an original method for quality assurance, which was developed by the team around Prof. Dr Markus Magnor from Technische Universität Braunschweig. The scientists take photos of the component. Then a digital image is modified in the computer until the simulation of the part is identical to the picture taken. After that, the scientists can calculate the deviation from the real component and make a statement about the production quality. "The initial results were impressive," says Dittrich. The new technology could ultimately simplify measurement technology for production. "This is a clever approach, which is only possible through interdisciplinary cooperation in PhoenixD."