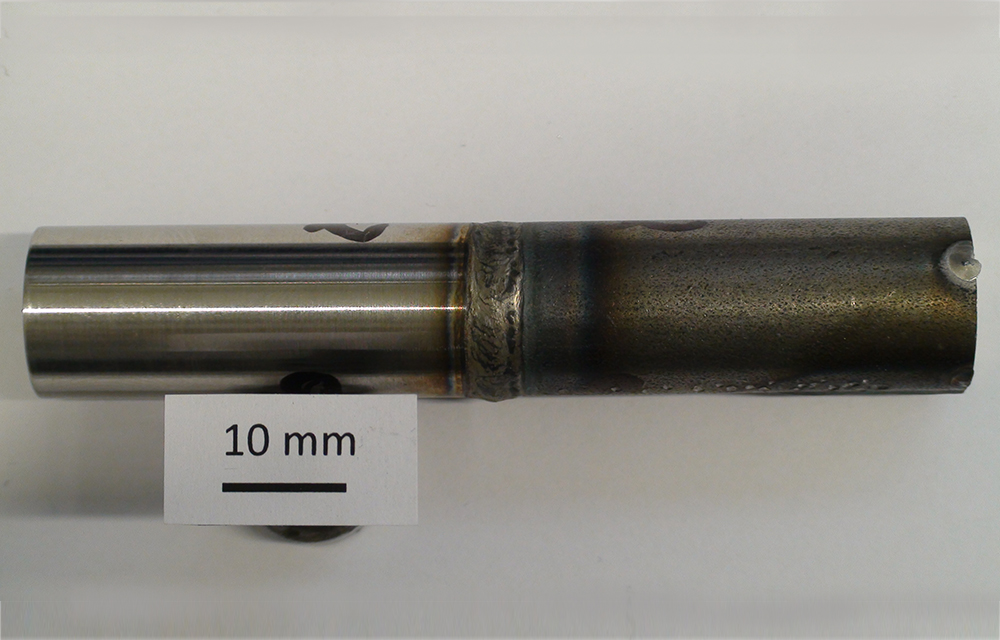

Joint forming requires a permanent, but flexible bond between two materials. The problem is that the mixing of materials during the welding process forms at the joint a brittle seam, so-called intermetallic phases which often do not withstand forming.

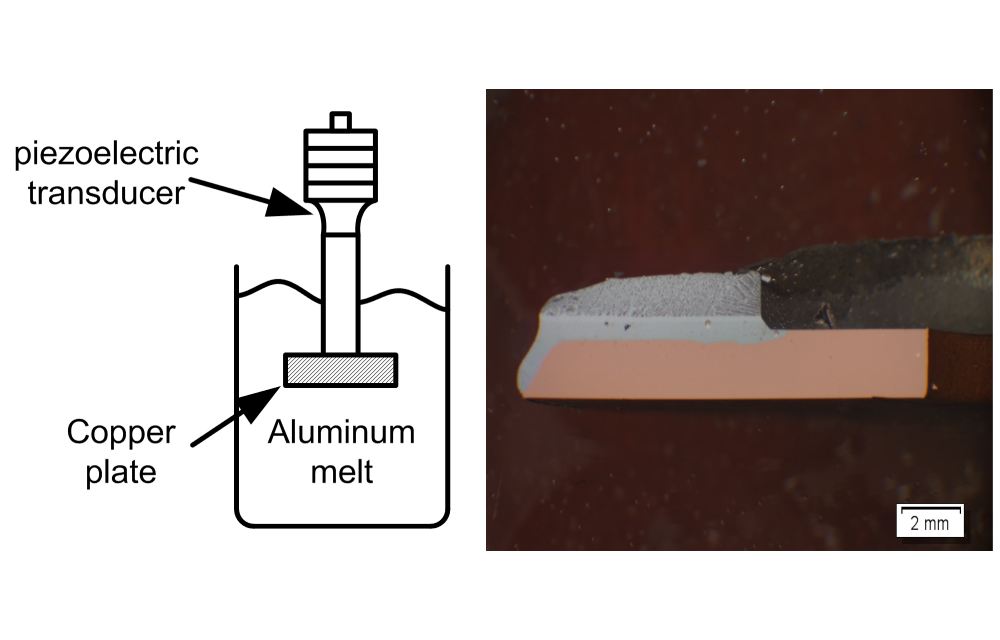

Ultrasound-assisted welding could enhance the formability of the weld seam. Researchers assume a positive influence of ultrasound on the material flow and mixing in the melting pool – and thus a reduction of the brittle intermetallic phases.

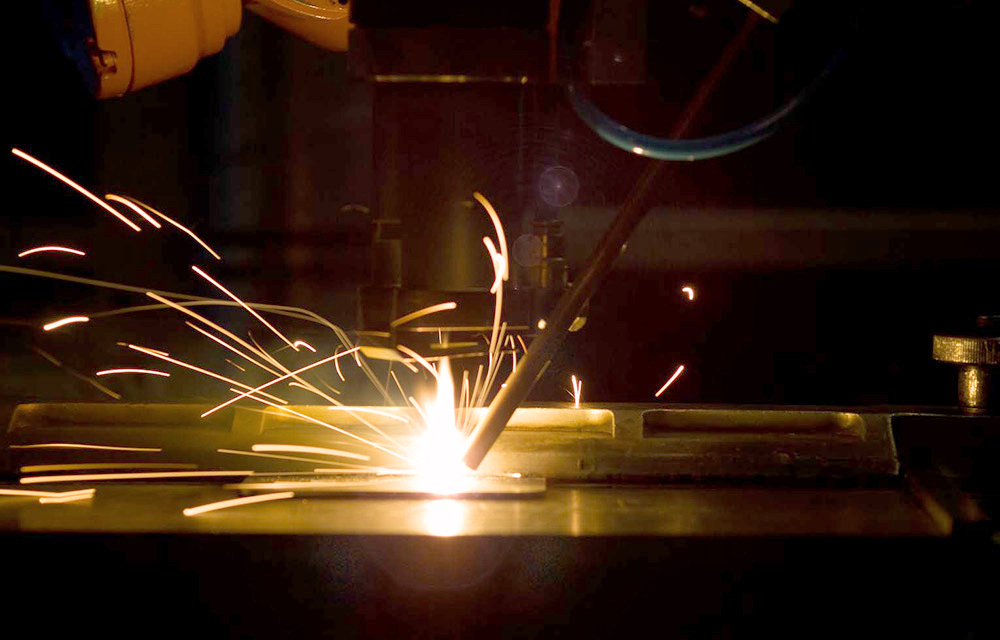

Research on this topic is done by three institutes in the joint subproject A3 of the Collaborative Research Centre (CRC) 1153: The Laser Zentrum Hannover (LZH) is developing a specific deep-penetration process, the Institute of Dynamics and Vibration Research (IDS) is developing the ultrasonic excitation of the molten bath, and the Institute of Materials Science (IW) is dealing with the material-related design of the welding process.