From surgery over safety systems towards tool technology: Micro cutting processes are used in a wide range of different fields of application. However, micro end milling processes cannot be realized economically so far, as the tools are quickly worn out and their individual production is too cost-intensive. For this reason, IMPT is developing a batch-capable manufacturing process, enabling an economic large-scale production of arbitrary micro end mill geometries.

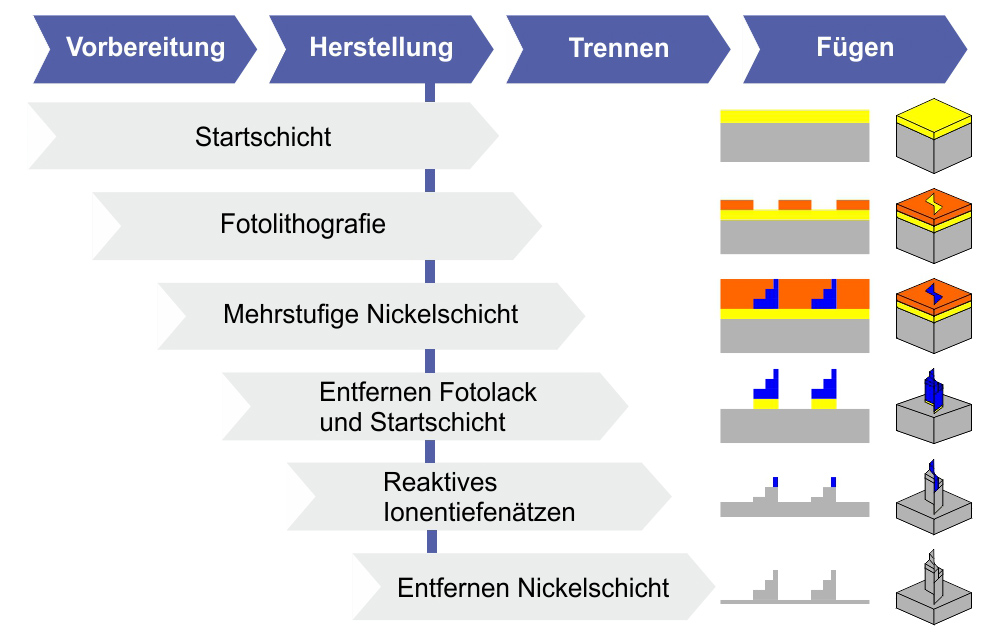

The hybrid manufacturing method – a combination of photolithographic structuring, deep reactive ion etching (DRIE) and mechanical separation – facilitates the production of micro end mills with a tool head height of more than 150 µm and a diameter below 30 µm. With this method, several thousand micro end mills can be manufactured at the same time. Mass production reduces manufacturing cost to a considerable extent.