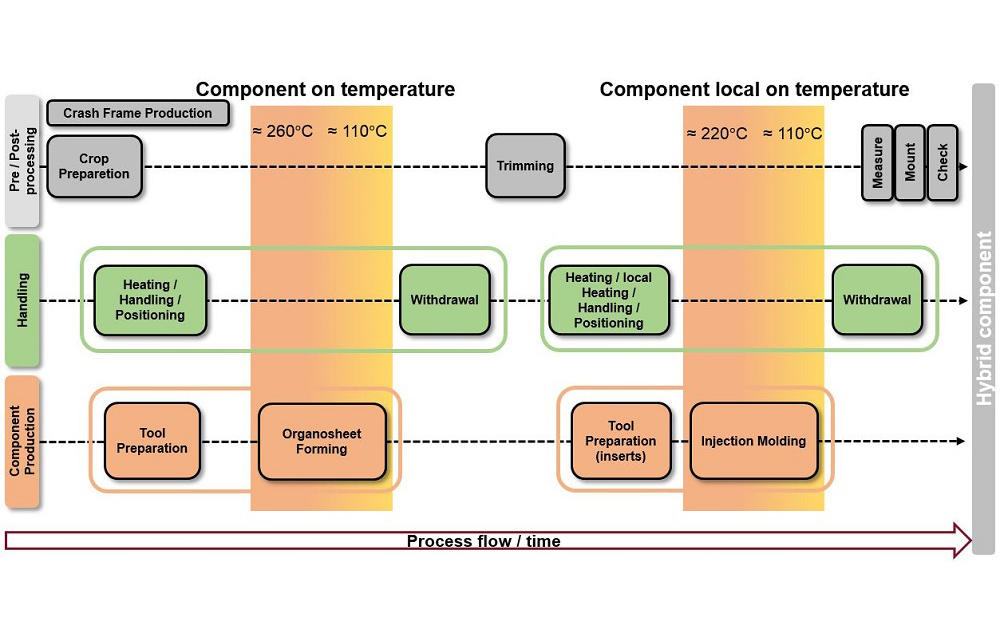

New materials require new production technologies – this is the reason why researchers participating in the joint research project ProVorPlus want to advance established technologies in order to facilitate automated large-batch production of so-called organosheets.

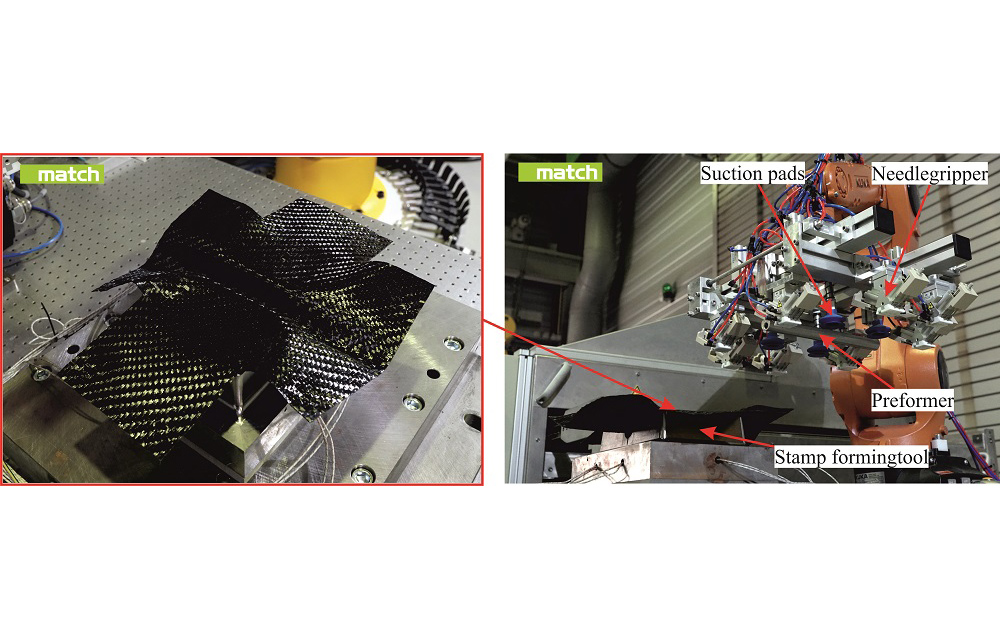

Organosheets are fibre-reinforced plastics (FRP): They consist of pre-impregnated glass or carbon fibre composite which is molten depending on the processing step and formed into a new shape. The problem: Whenever heated, the organosheet loses its stiffness and gets dimensionally unstable. Conventional robots can then neither grip nor position the unstable material. For this reason, series production has not been possible so far.

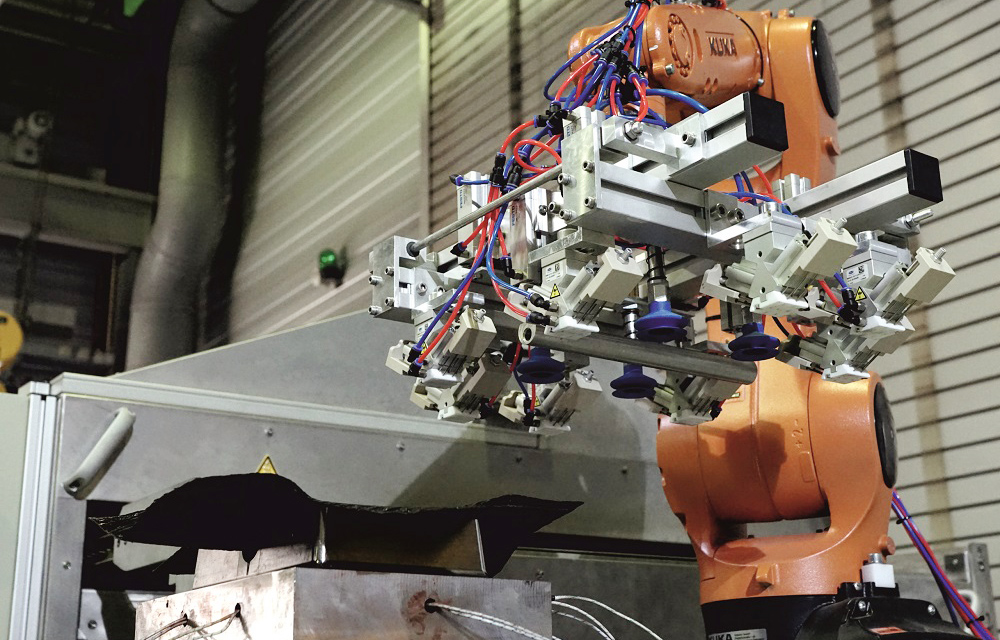

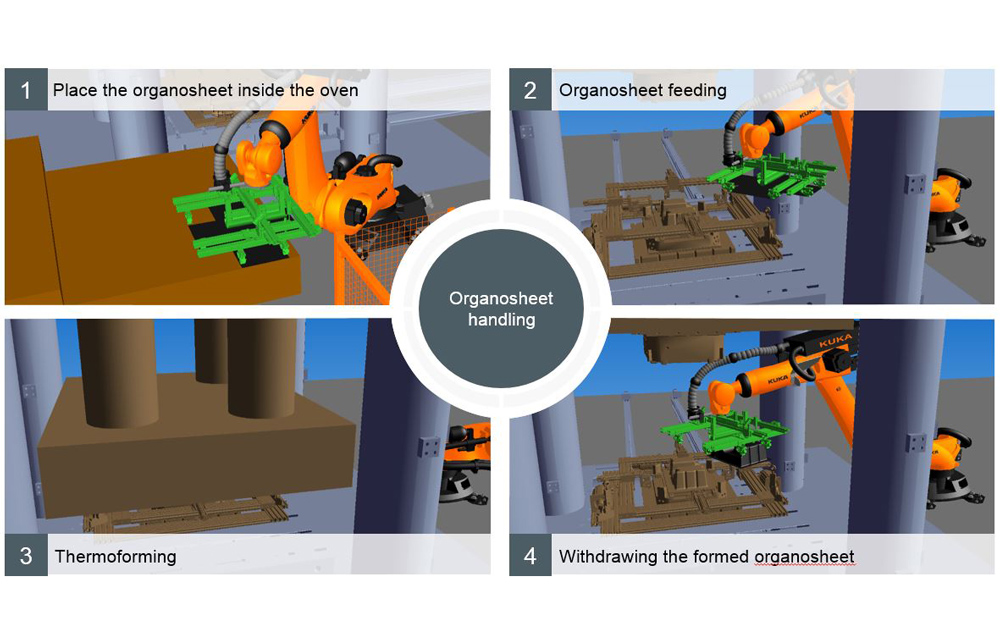

The Institute of Assembly Technology (match) of Leibniz Universität Hannover is developing a new technology allowing processing and handling of organosheets at various temperatures, states of aggregation and geometries. In this connection, the focus is on short cycle times and efficient production.