Composite materials such as carbon fiber-reinforced plastics (CFRP) are excellent for lightweight construction and are used in various industries including automotive and aerospace. Scientists at the Laser Zentrum Hannover e.V. (LZH) aim to simplify the processing of CFRP and sandwich materials. Together with INVENT GmbH and KMS Technology Center GmbH, they have developed a method with an associated system setup in which the beam of a high-power laser is diffractively split into up to 25 sub-beams and used to create multiple bores simultaneously. With this process, they were able to produce bores with diameters ranging from only 1.2 mm to 0.25 mm. This makes them smaller than bores that can currently be achieved with conventional mechanical methods in sandwich and CFRP materials.

Process Optimization for Industrial Use

During the development of the method, the scientists first narrowed down and optimized the most relevant process parameters. They also had industrial use in mind from the beginning: Users in production should later be able to ideally adjust the drilling processes according to clear specifications. Through process development, the LZH scientists were able to significantly improve bore quality.

There is a clear efficiency gain from utilizing the excess power of the TRUMPF high-power laser used: It is used to drill multiple holes simultaneously. For this purpose, the laser beam is split into sub-beams by specially designed diffractive optical elements, allowing it to impact the material at multiple locations and create bores. Ideally, this can be done with up to 25 sub-beams, reducing the drilling time to only a 25th of the original time, which is then less than a tenth of a second per bore – a value that is not achievable with conventional methods even for larger bores.

Sound Insulation in Lightweight Construction as an Application Area

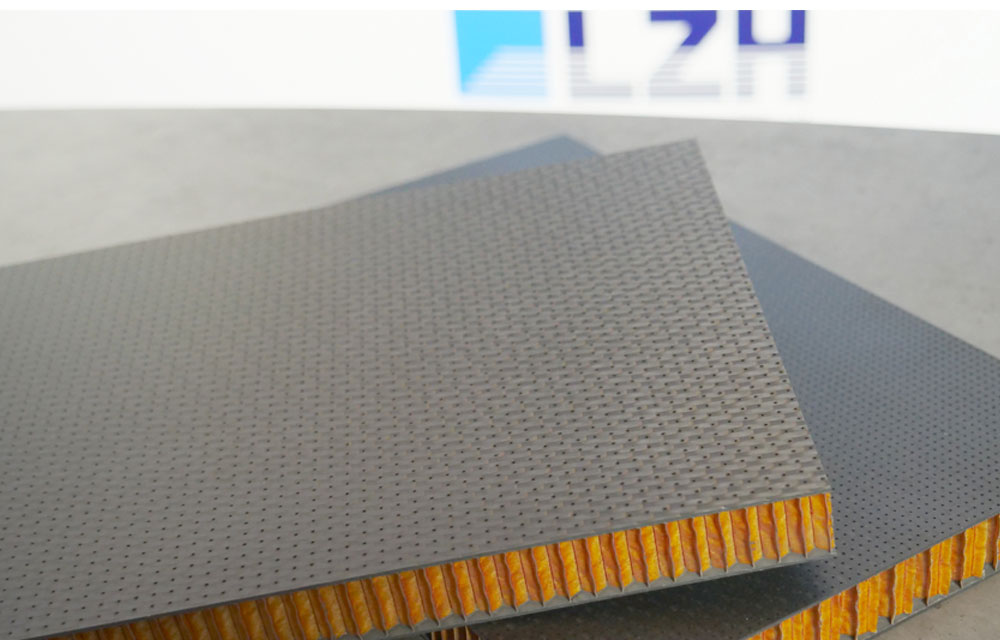

Micro-drilling with lasers is particularly interesting, for example, in aviation. To reduce aircraft noise emissions, sound-absorbing cladding elements are used, for example, to line engines. Such components are often made from CFRP or CFRP sandwich materials and then provided with many small bores over a large area. Micro-drilling with lasers is particularly suitable for these so-called acoustic drilling because laser drilling is contactless and thus force- and wear-free. High costs due to tool wear and quality problems due to dull drills are thus eliminated.

The method can also be used beyond aviation in the production of sound-absorbing elements in automotive construction and in all systems where sound insulation is necessary and/or lightweight materials are advantageous. In acoustic tests, the sound insulation properties of the laser-drilled sandwich panels were evaluated as excellent by the project partner INVENT GmbH. The mechanical properties of the laser-drilled samples have also proven to be excellent. By using optomechanics manufactured by KMS Technology Center GmbH, the method also enables high flexibility in bore diameter and pattern without the need for a tool change.