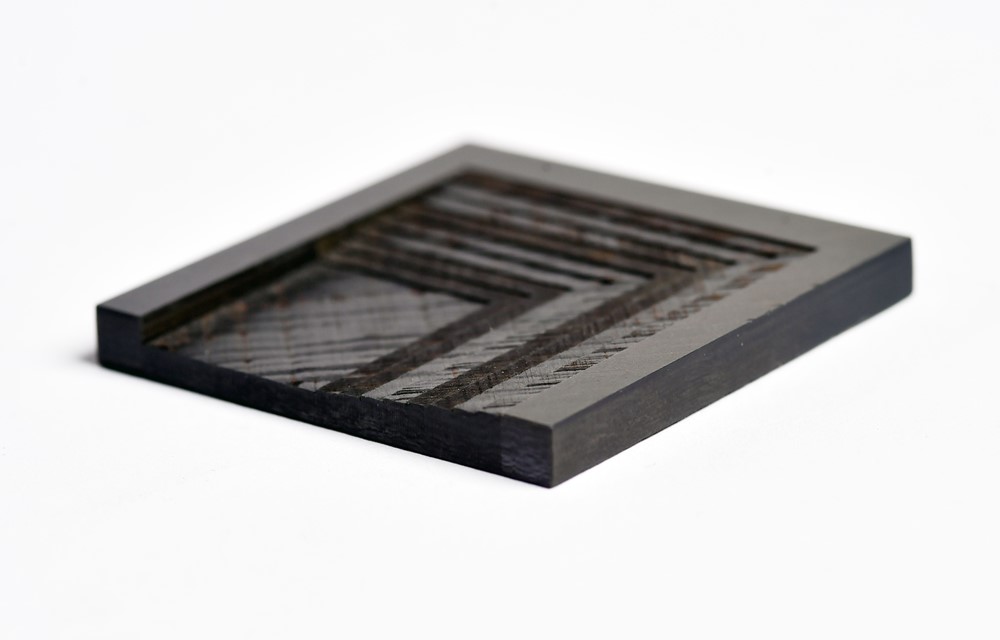

Laser-machined metals and fiber composites are widely used in lightweight construction. Experts have found ways to further increase the efficiency and throughput of the laser processes – for example through innovative beam sources with adapted beam shaping, process-adapted measuring and control technology as well as new machining methods with low thermal damage to the material.

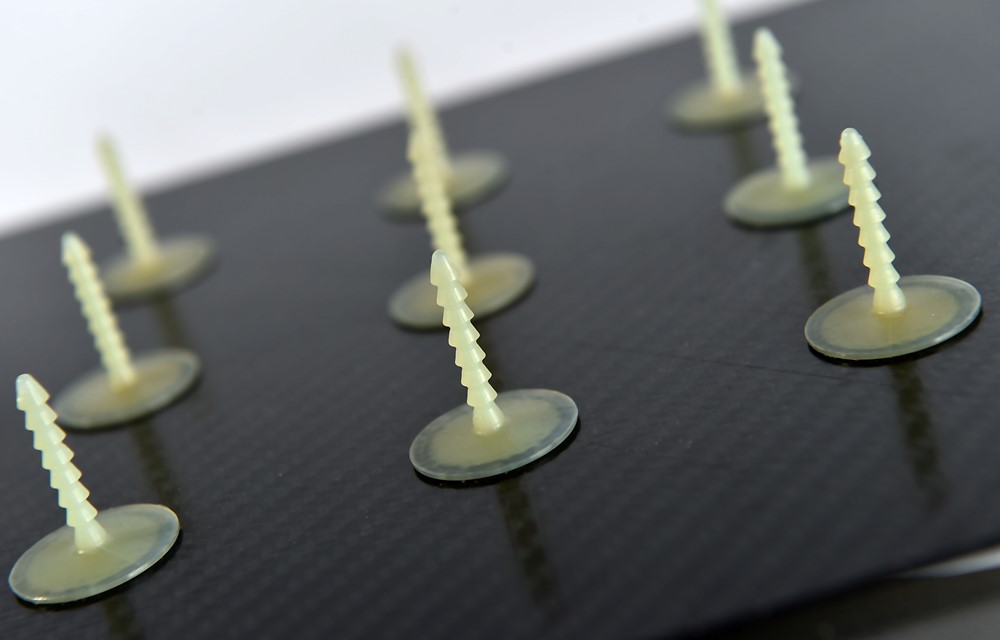

Using highly-resolved spatial and temporal inline measurements of the ablation depth, the repair of components made of carbon fiber reinforced plastics (CFRP) can be prepared even more precisely. Thus, defective areas can be removed more accurately with the laser, and it becomes easier to precisely insert repair patches, too.

The laser processing of lightweight materials generates potentially hazardous emissions. Therefore, presentations at the symposium will also address exhaust and filtration solutions.

The registration for this German-language event in Hannover is open at www.lzh.de/de/photonischer-leichtbau until 1 March 2018.