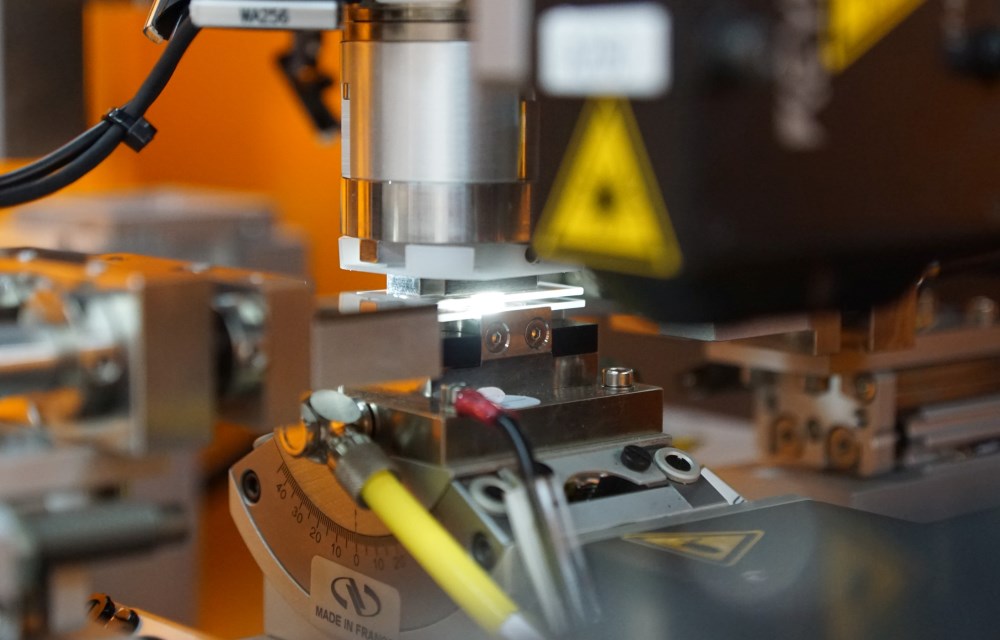

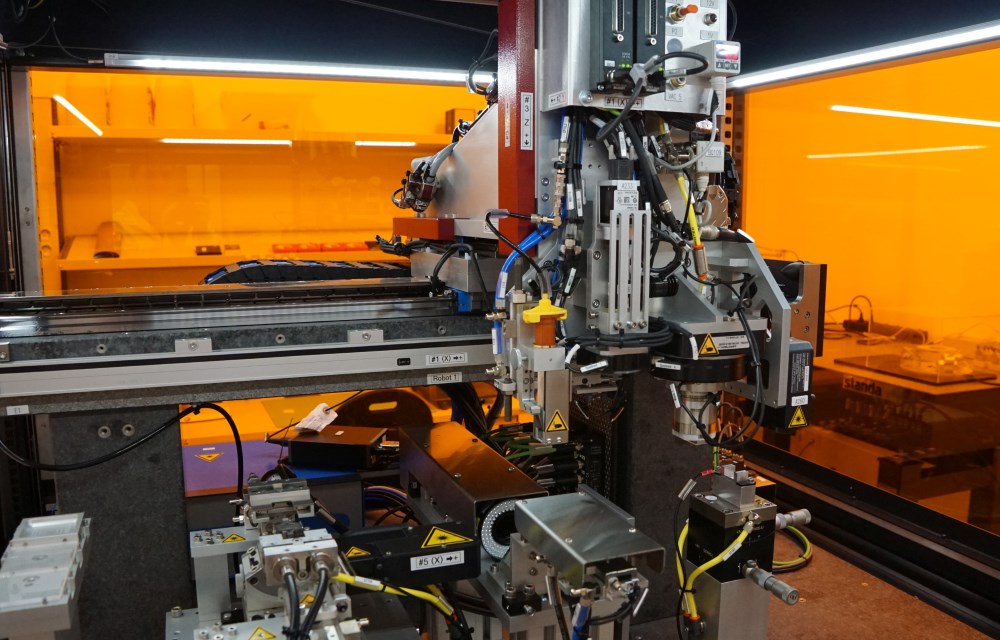

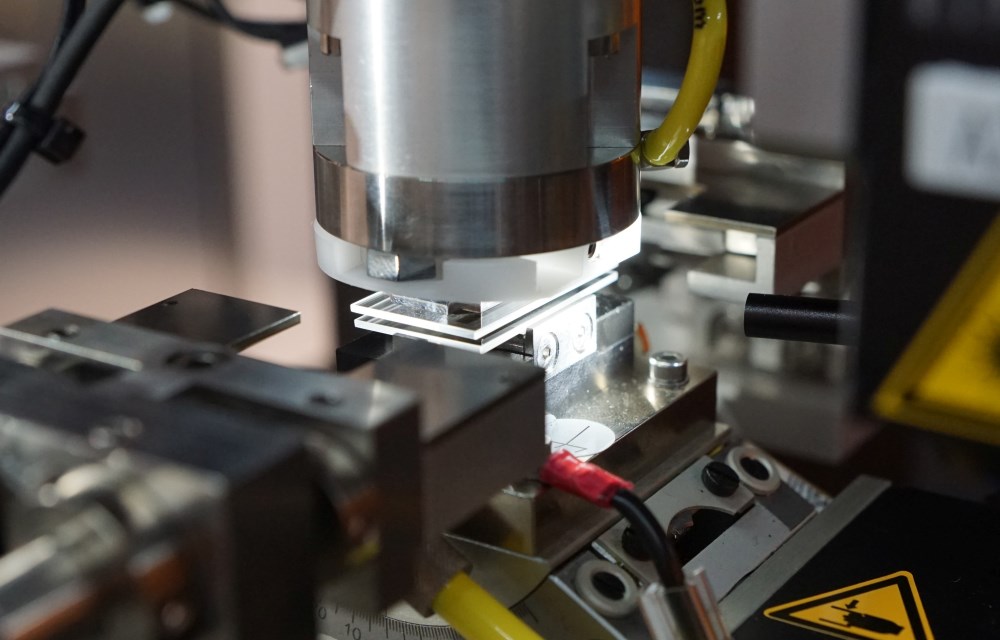

The centrepiece of the new high-precision assembly cell is the precision robot "Autoplace 670" of the Swiss company unitechnologies SA. Its end effector’s repeatability is less than 0.7 micrometres. In combination with the other components, as for example cameras, distance sensors and high-precision positioners, an assembly accuracy of less than 7 micrometres is achievable.

match achieves highest flexibility by specifically applying sensor technology. Using multi-axis force/torque sensors, the researchers developed sensor-supported assembly processes, as for example the force-controlled joining of components. The institute’s equipment further includes a positioner with nanometer resolution of the Oldenburg company SmarAct, a so-called hexapod, permitting high-precision 3D assembly processes with a free positioning in six degrees of freedom.

The investment was funded by the German Research Association (DFG). With the purchase of the flexible assembly cell, match is now able to intensify the institute’s research work in the field of precision assembly.