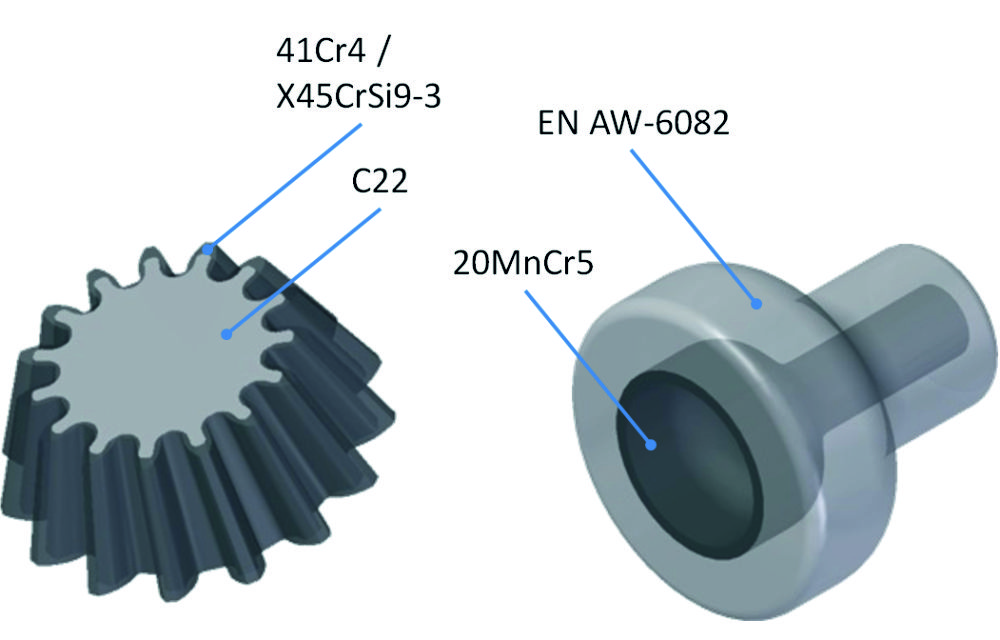

Whether drive shafts or gear wheels: The trend is towards lightweight vehicle parts that are also able to withstand higher and higher loads. The solution is a combination of materials. The question is whether hybrids can withstand joint forming without rupturing at the joint? The Institute of Metal Forming and Metal Forming Machines (IFUM) is dealing with this question in the subproject C1 of the Collaborative Research Centre "Tailored Forming".

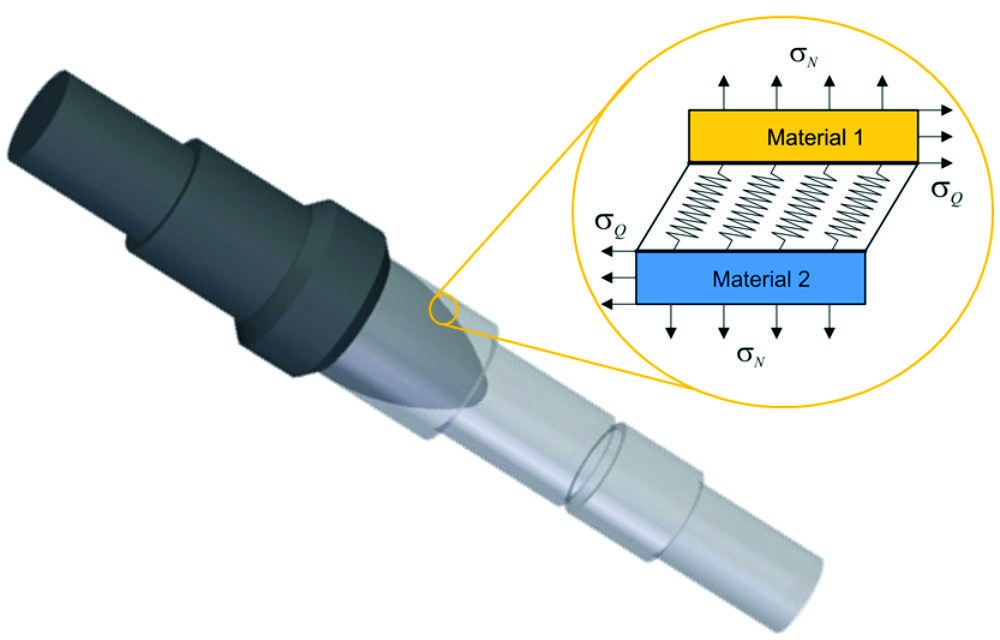

The load on the interphases is determined by tension and compression tests carried out on cylindrical specimens with differently arranged interphases. The test results are then used to create a model. The material behaviour in the intermediate layer is identified by interphase models based on cohesive elements. By this means, the researchers can predict the damage or failure of interphases – and avoid it in the future. Based on their expertise, the process design can be adapted in such a way that hybrids are able to withstand joint forming.