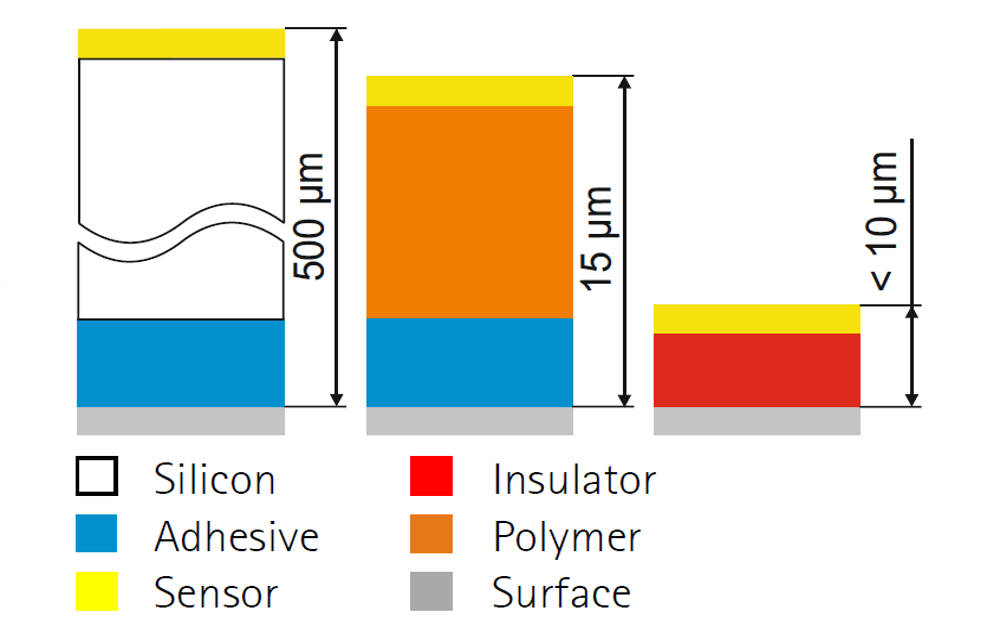

Sensors detect the air-mass flow in combustion engines, deformations in machine tools and humidity in the passenger compartment. Micro sensors are generally manufactured on carrier substrates and glued to the measuring point. The disadvantage: Thick carrier substrates and the ageing of glue may cause incorrect measurements.

Within the scope of the Collaborative Research Centre 653, a novel approach managing without the aforementioned intermediate layers is investigated at the Institute of Micro Production Technology (IMPT). Sensors are directly deposited on technical surfaces reducing measurement errors and the thickness of sensors (see Figure 2).

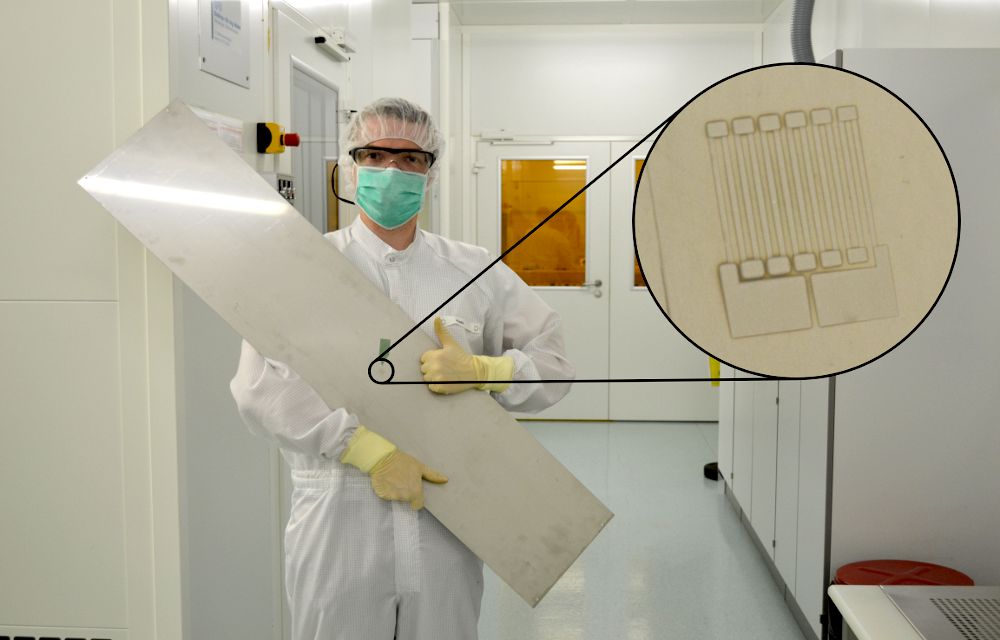

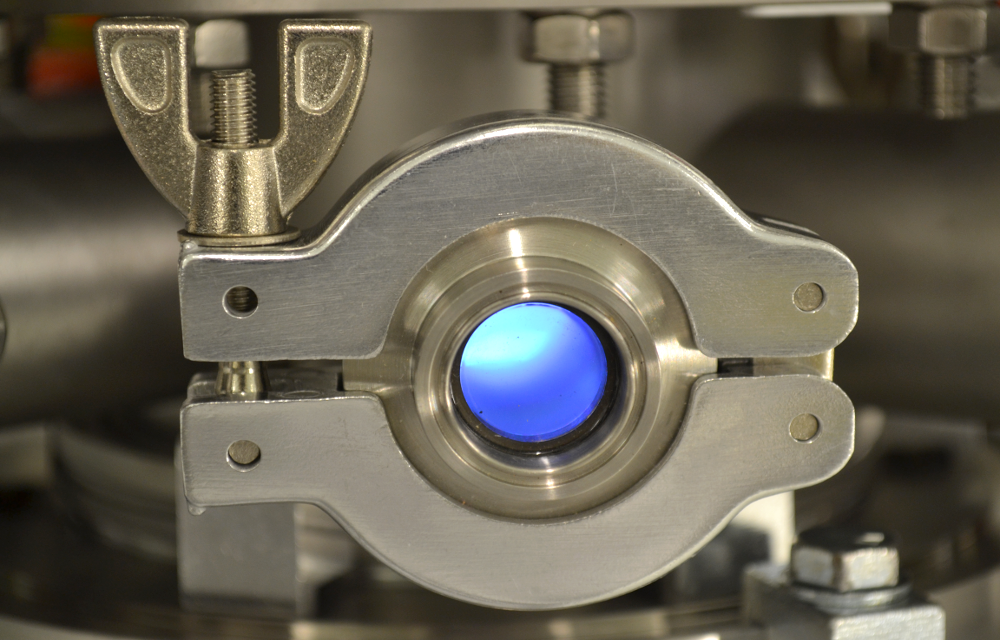

To coat components of arbitrary size with sensors, the IMPT has invented and patented a mobile coating system. A prototype was constructed in cooperation with an industry partner. In the past, components had to be inserted into the vacuum chamber of a coating system. In future, the chamber is simply put on the component, i.e. the surface of the component is the chamber’s one side. In this way, the system can directly be used in an industrial production line.