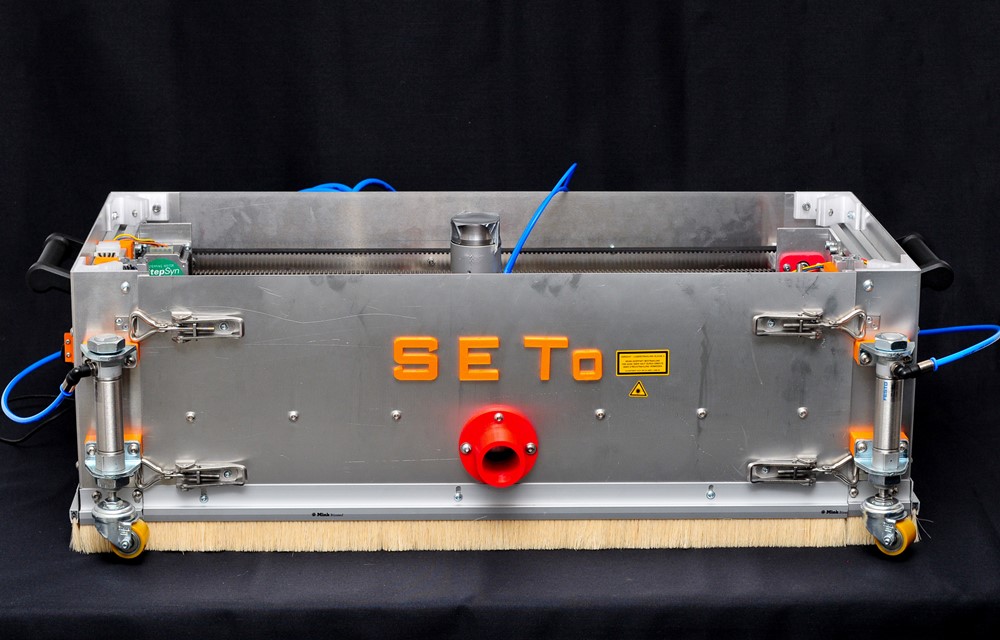

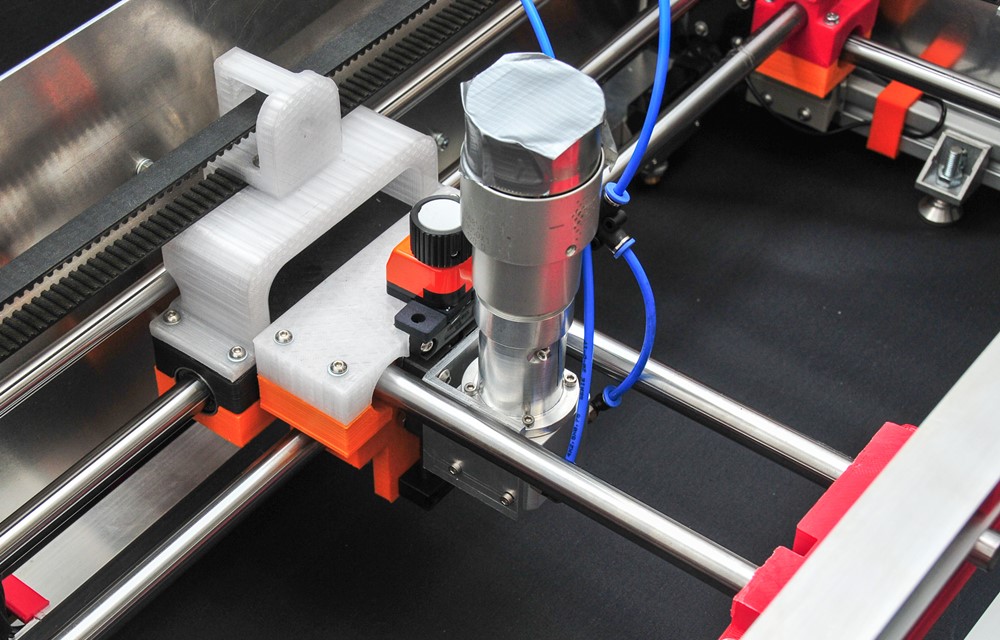

The existing laser processing system was, up to now, not very flexible to use. Therefore, the partners SET Scientific and Efficient Technologies Ltd. and LZH further developed the system within the course of the assessment project MOBILLAS under the roof of the EU project LASHARE, with the focus on increasing the flexibility. For this purpose, SET has, on the one hand, increased the processing length, and, on the other hand, implemented a second axis to extend the machining area.

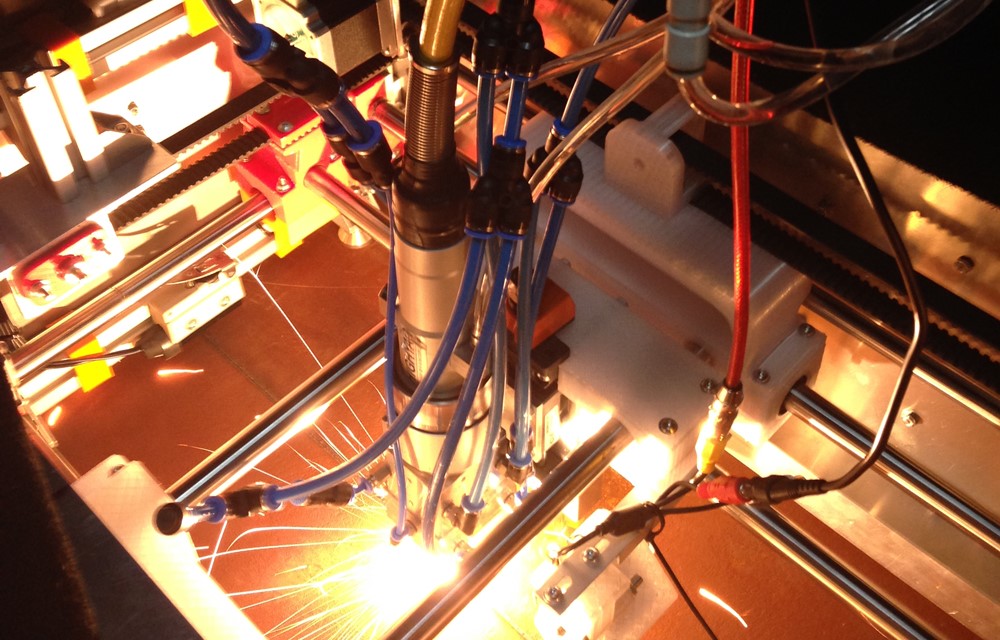

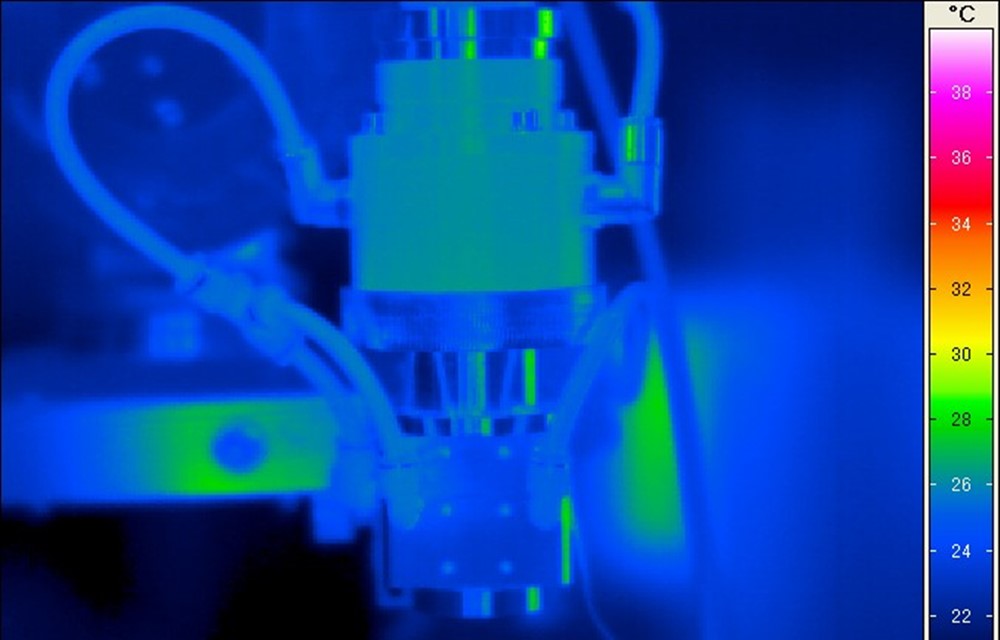

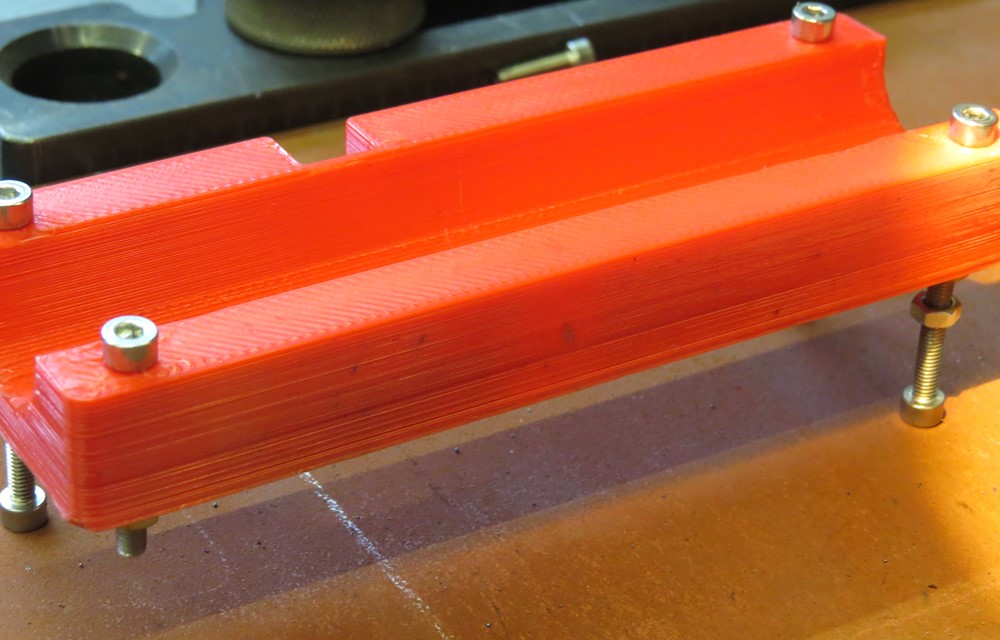

The usable laser output power could be increased from 2 kW to 6 kW. At the same time, SET reduced the size of the laser optic. Depending on the requirements, the system is now available in several modules. 3D-printed components made it possible to further reduce the weight of the protective housing. Despite all these changes the mobile system is still laser safe.

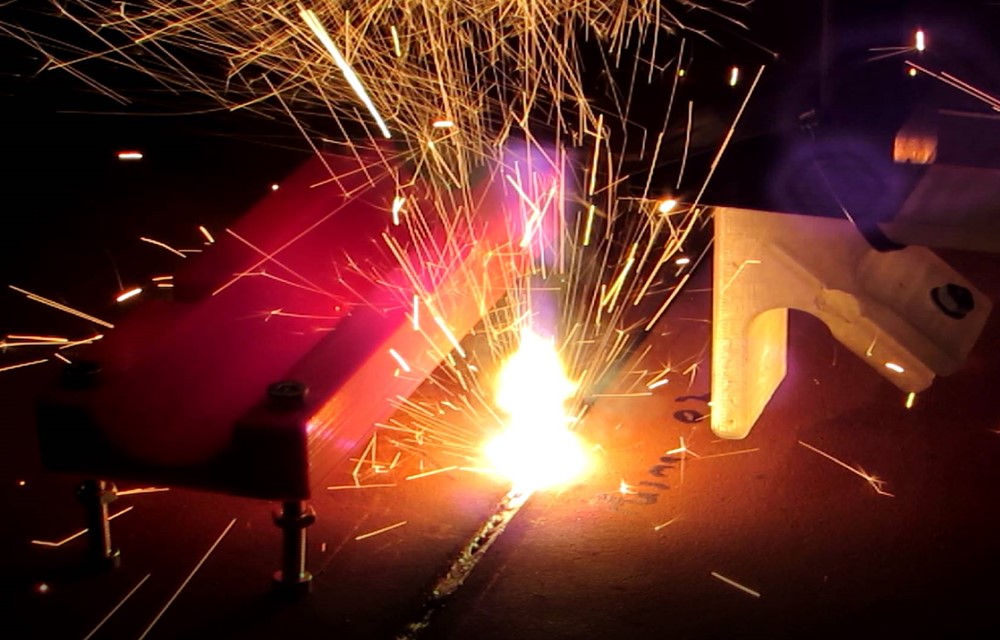

SET and LZH tested the improved mobile laser processing system both under lab and industrial conditions in a shipyard. The system can cut 6 mm thick metal sheets at a sufficiently high speed, and achieves practically relevant welding depths through joining. For laser removal the system is less suitable in the present version. In the future, the system can make the processing and repair of large components in heavy industry and shipyards and pipelines much easier.