Aluminium alloy lightweight structural steels, also called ultra-high carbon (UHC) steels, have a ten percent lower density than today’s high-performance steels. Consequently, they have a lighter weight – at comparable strength. The drawback: Machining of UHC steels is not so easy.

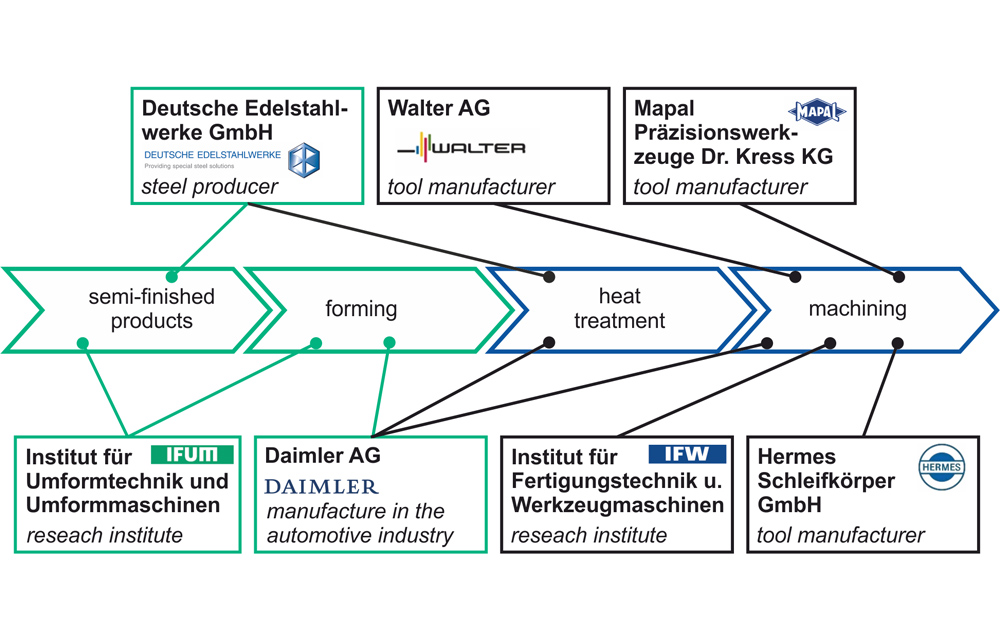

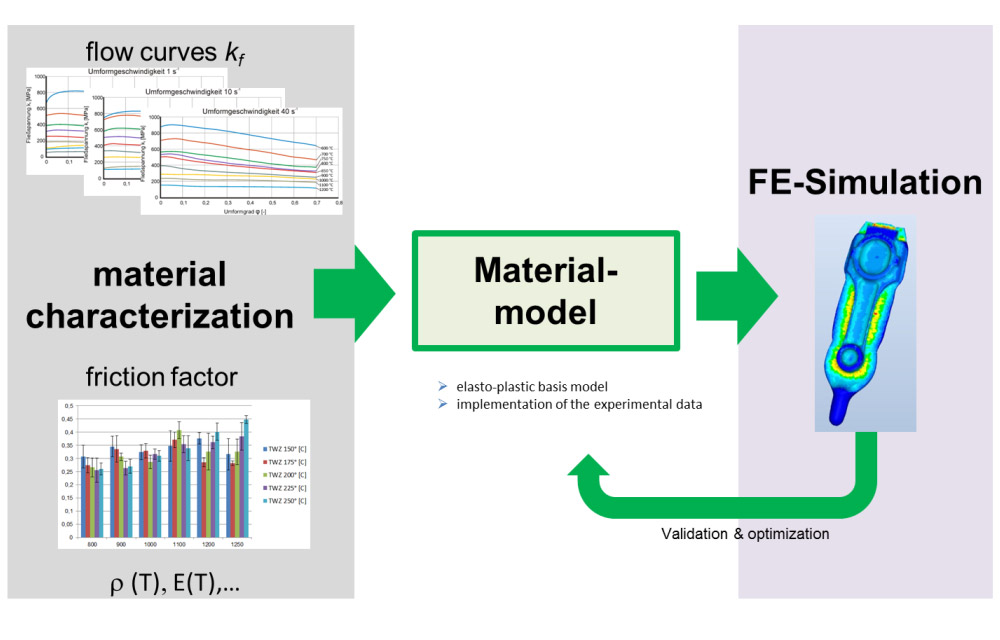

Within the scope of the project "IPROM", researchers at the Institute of Forming Technology and Machines (IFUM) carried out a complete material characterization of the lightweight structural steel, in order to examine its behaviour during the forming process. The result: Higher forces are needed to form the novel material. Due to the low thermal conductivity, high temperatures are developed in the tool during the machining process. Moreover, UHC steel is quite brittle.

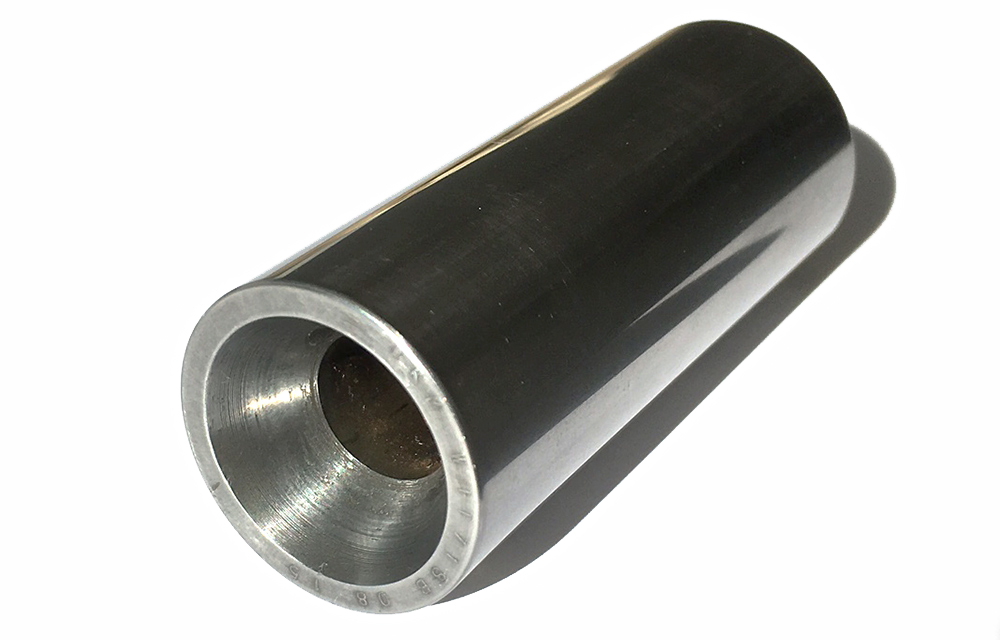

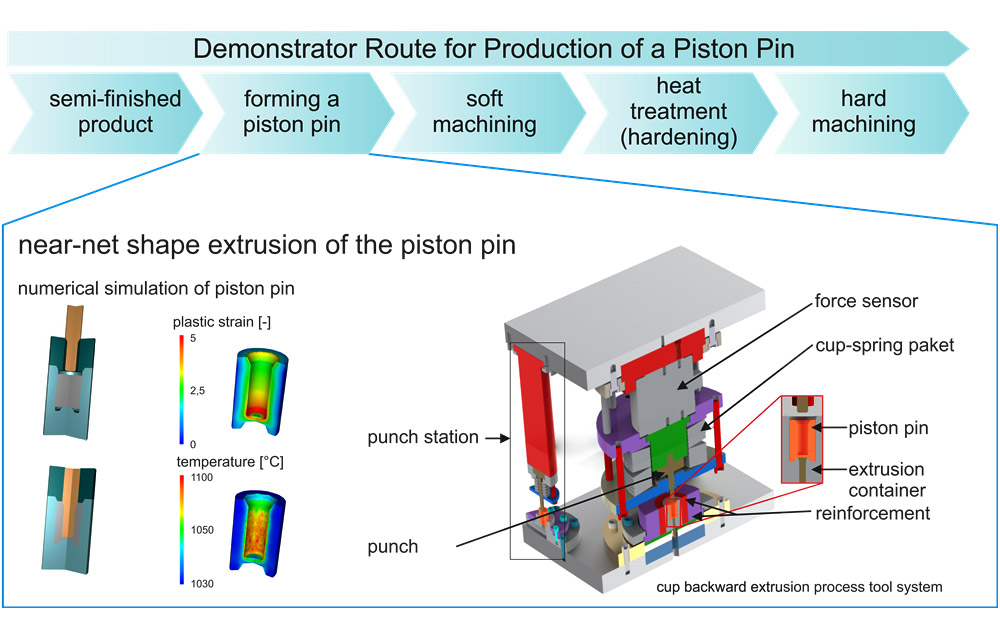

Forming and machining of UHC steel is difficult when using conventional tools and manufacturing processes. In cooperation with IFW and project partners from industry, IFUM has therefore simulated and developed a completely new process route – using the example of the production of piston pins (see Figure 4).