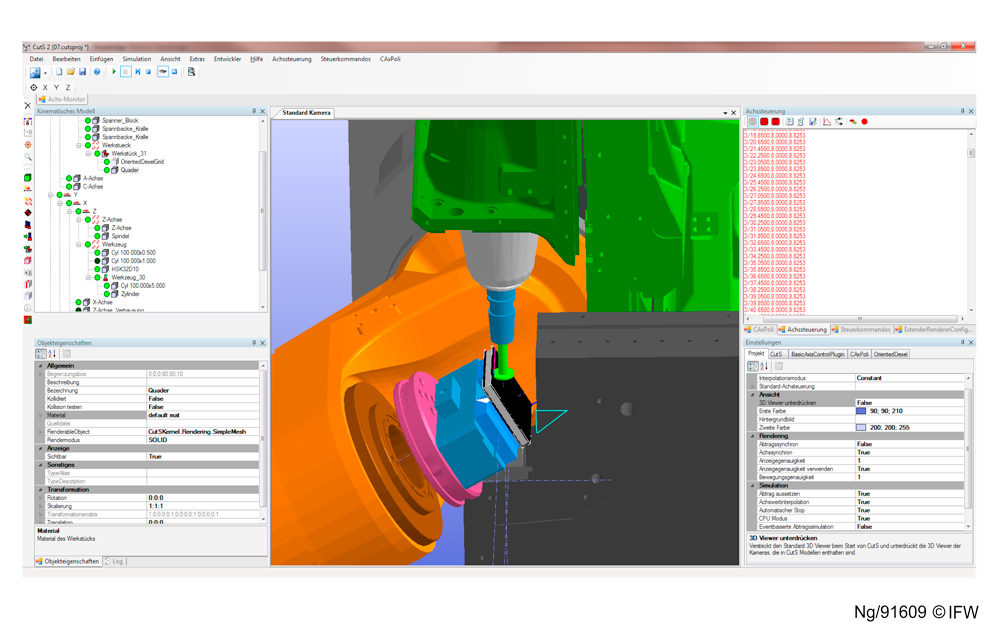

For an automated tool path planning and implementation, the workpiece’s surface topology has to be identified prior to the machining process. This is the basis for the first machining steps which are defined by a planning algorithm embedded in the institute’s own simulation software IFW CutS. In this way, it becomes possible to predict the machining result and select the optimal machining strategy depending on the respective processing status.

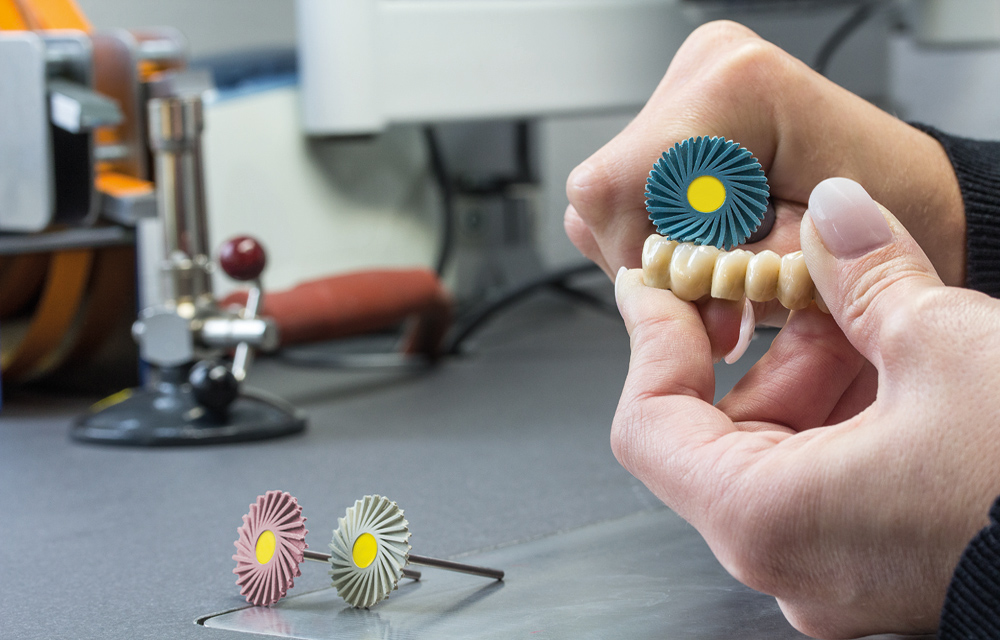

After the first polishing step, the workpiece surface is measured again, and the automatedly polished surface is compared to the simulation result. This feedback allows the system to adapt the process parameters and to improve the machining process constantly.

By and by, the adaptive system is capable of machining more and more complex workpieces, thus meeting highest surface requirements. The vision of the future: automated machining of unknown geometries.