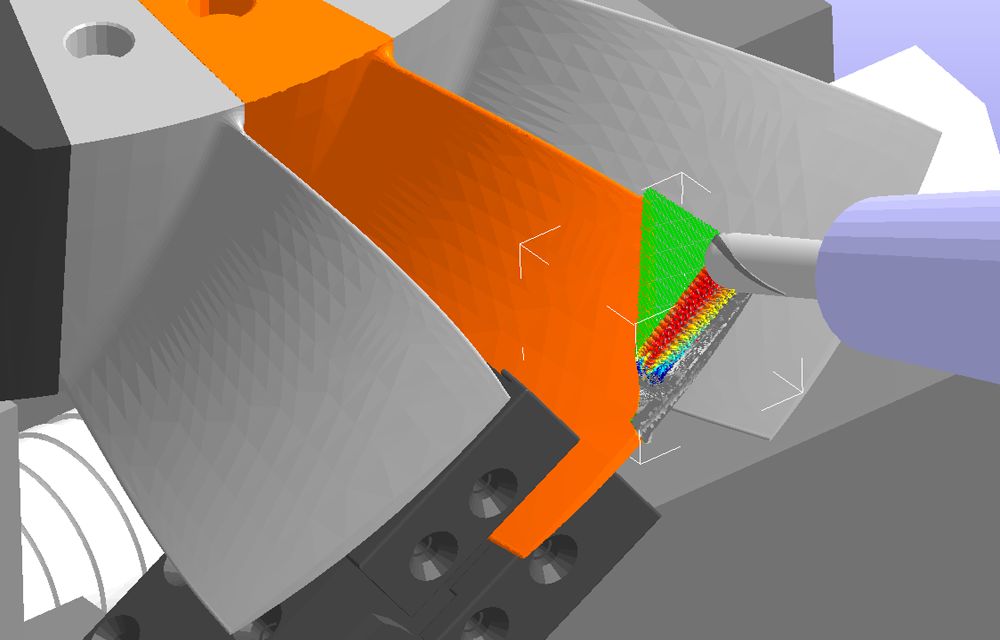

When repairing turbine blades, new material is welded to the blades and then removed by a machining process. During this so-called re-contouring, the surface quality is a decisive factor, as it is crucial for the aerodynamics and thus for the efficiency of the regenerated turbine. In addition, the residual stress in the surface has great influence on the functionality and lifetime of the component.

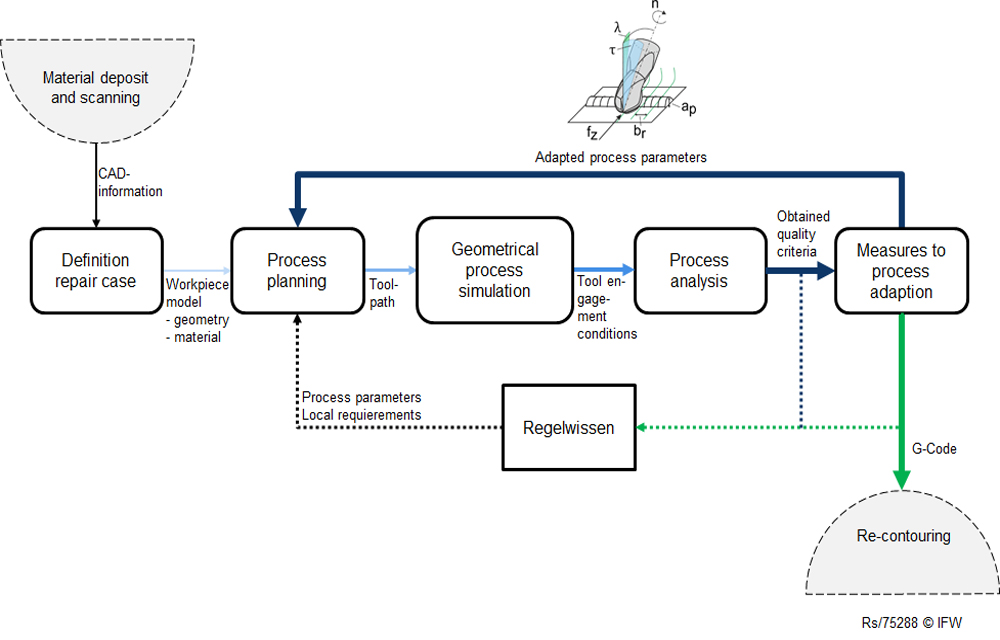

Within the scope of the Collaborative Research Centre 871 "Regeneration of Complex Capital Goods", the Institute of Production Technology and Machine Tools (IFW) investigates how re-contouring processes can be optimized. A specifically developed software program creates the tool paths for the machining process. Next, the milling process is simulated and the result evaluated: If, for example, the surface is not sufficiently smooth, the process is readapted. With the help of simulation-based design, the researchers additionally want to create optimal residual stress.