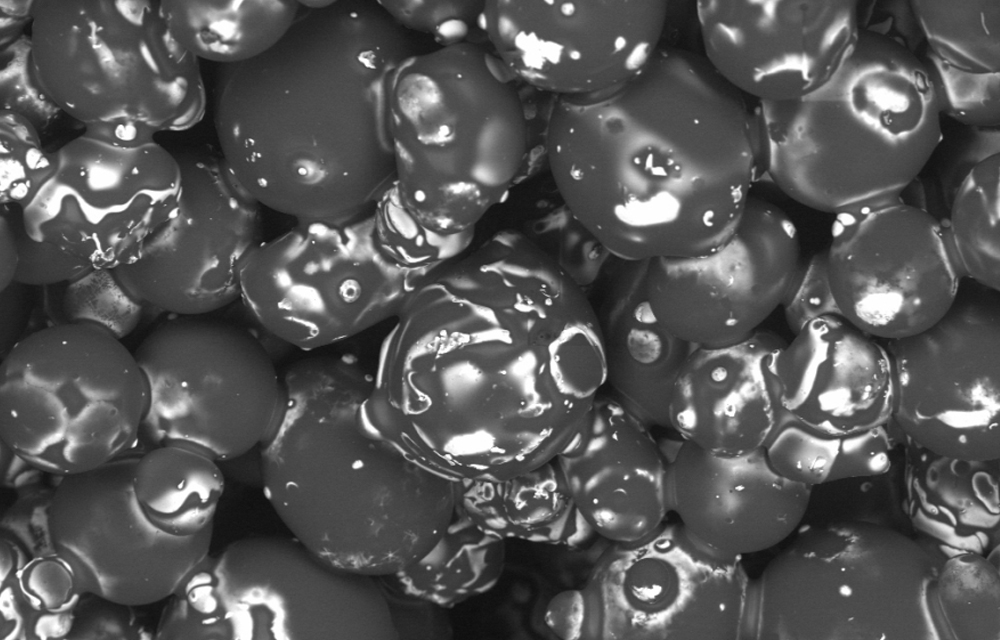

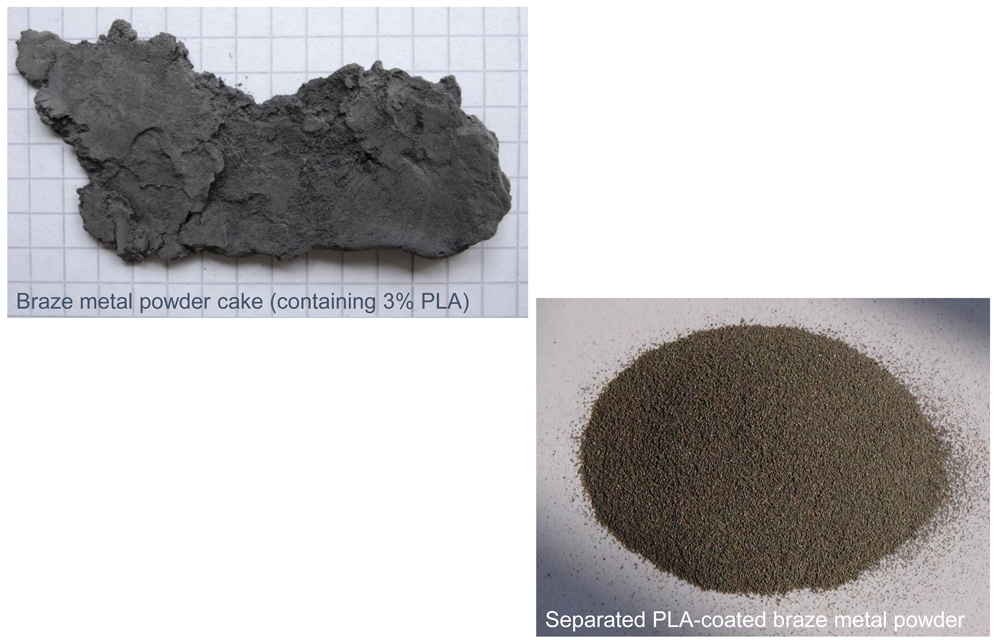

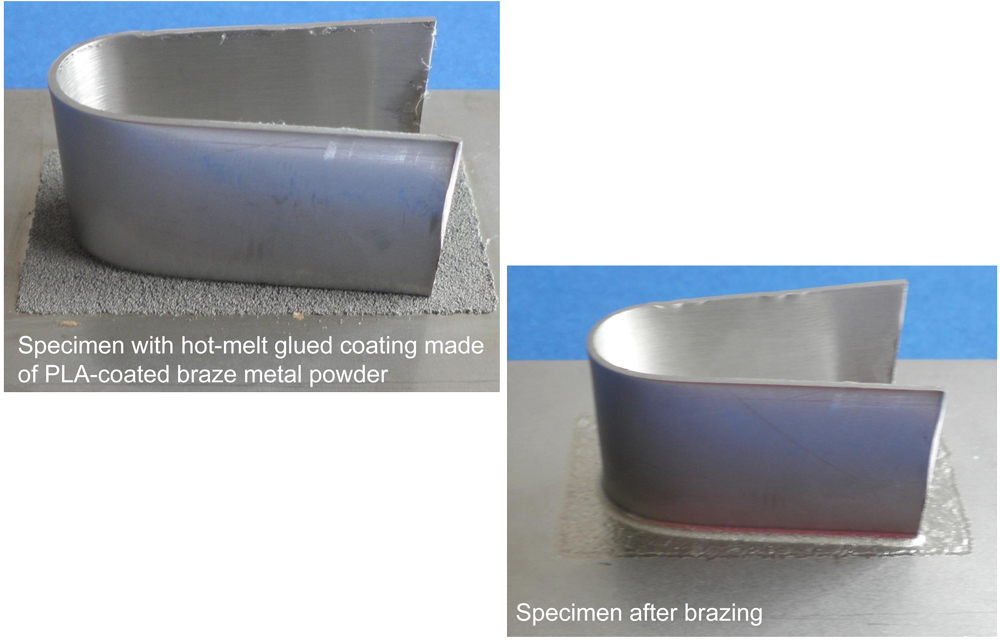

Researchers at the Institute of Materials Science (IW) have succeeded in coating metallic brazing powder particles with polylactide (PLA). On the one hand, the metallic particles are insulated by the thermoplastic coating, so that it is possible to apply them by means of electrostatic powder coating processes. On the other hand, the thermoplastic coating ensures the firm adhesion of the brazing powder to the metal surface. Thermal treatment above PLA melting temperature at approx. 200°C allows to create storable and chargeable thermoplastics prior to brazing.

PLA-coated powders can also be used for an easy production of solder preforms. PLA-bonded nickel-based solder is applicable in a vacuum furnace as well as under inert gas. There are no specific requirements concerning processes or furnaces.

Thermoplastic coating does not affect the brazed joints, because PLA decomposes during brazing already at 350°C without leaving any residues.