Recycling textile products and textile fibers in injection-molded components for lightweight construction applications in order to protect the environment and conserve resources in the long term – IKK and Gerry Weber are working together on this research goal.

The fashion company provides the materials and receives information on recycling technology issues in the return transfer. "Being able to participate in the development of innovative recycling processes is forward-looking for us and fits into our sustainability strategy," explains Angelika Schindler-Obenhaus, COO at Gerry Weber. "The fact that waste from the textile industry, beyond upcycling and second-hand, is recycled in a sensible and ecologically balanced way is essential for sustainable business. In this way, textiles can provide valuable raw materials in the future after their use has come to an end."

Thinking about recycling early on

Recycling of modern textiles is no simple task. To optimize the usage properties of apparel textiles, additional auxiliaries and additives are used during production. In addition, blended fabrics consisting of different synthetic fibers are frequently produced. "After the use phase, however, this highly variable chemical composition of apparel textiles poses a major challenge for the development of effective and economical recycling approaches," says Professor Dr.-Ing. Hans-Josef Endres, the head of IKK. In the future, he says, it will therefore be necessary to consider how materials can be recycled at a later stage, right from the development stage.

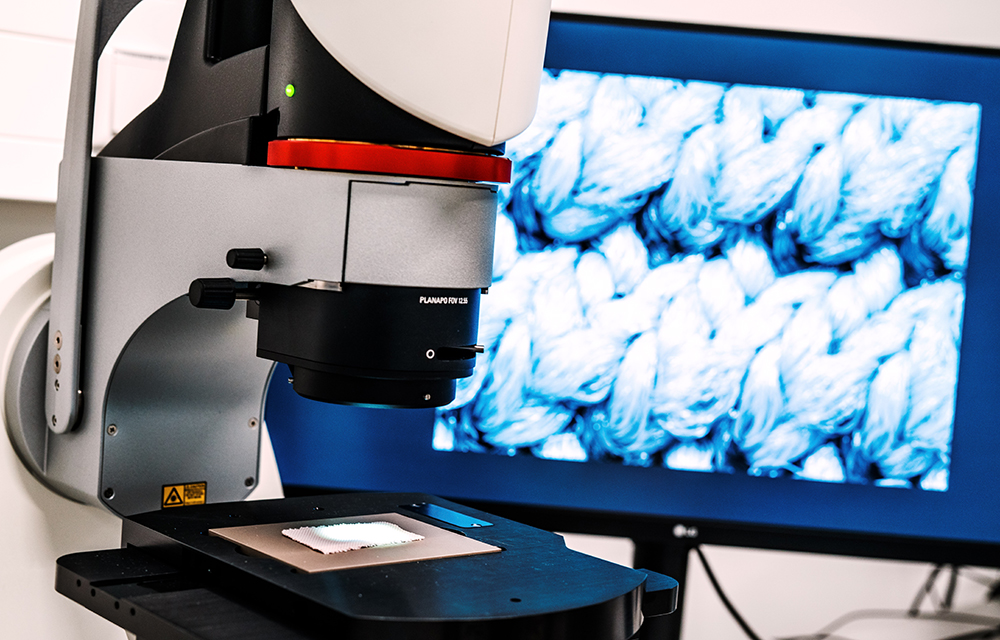

Mechanical recycling of textile waste

As part of their joint research activities, IKK and Gerry Weber are investigating the potential of mechanical recycling for various textile wastes. "These activities include a systematic characterization of diverse textiles as an input stream, process optimization of individual recycling stages, and technology transfer back to fashion companies and textile manufacturers to optimize material compositions for both the use and recycling phases," reports project leader Dr. Madina Shamsuyeva of IKK.