Modern Industry 4.0-compliant data networking requires the presence of distributed data storage units. The most crucial factors are their reliability and re-writability. Current data storage technologies suit these needs to only a limited extent.

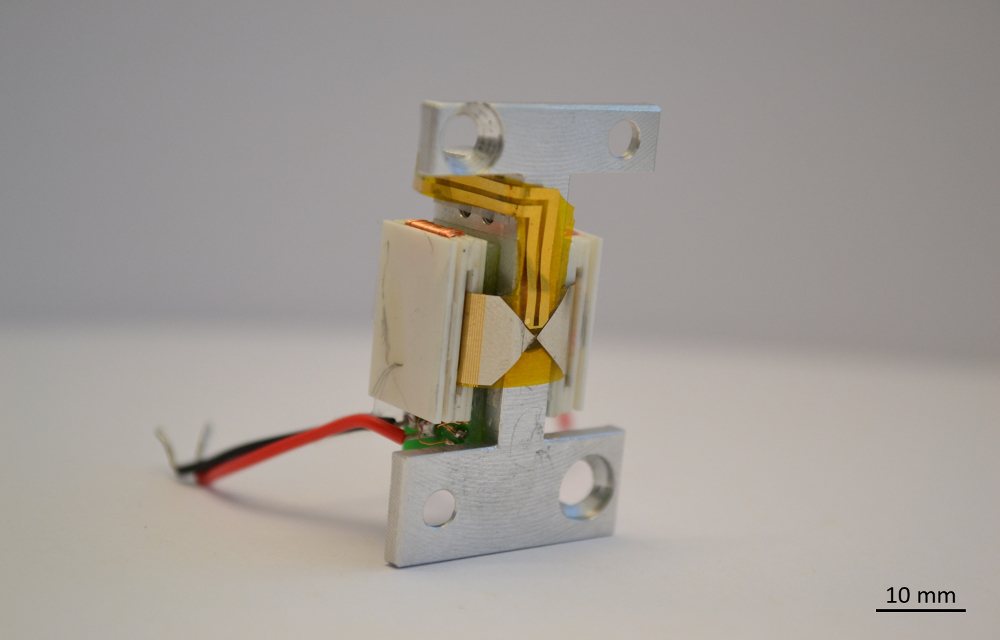

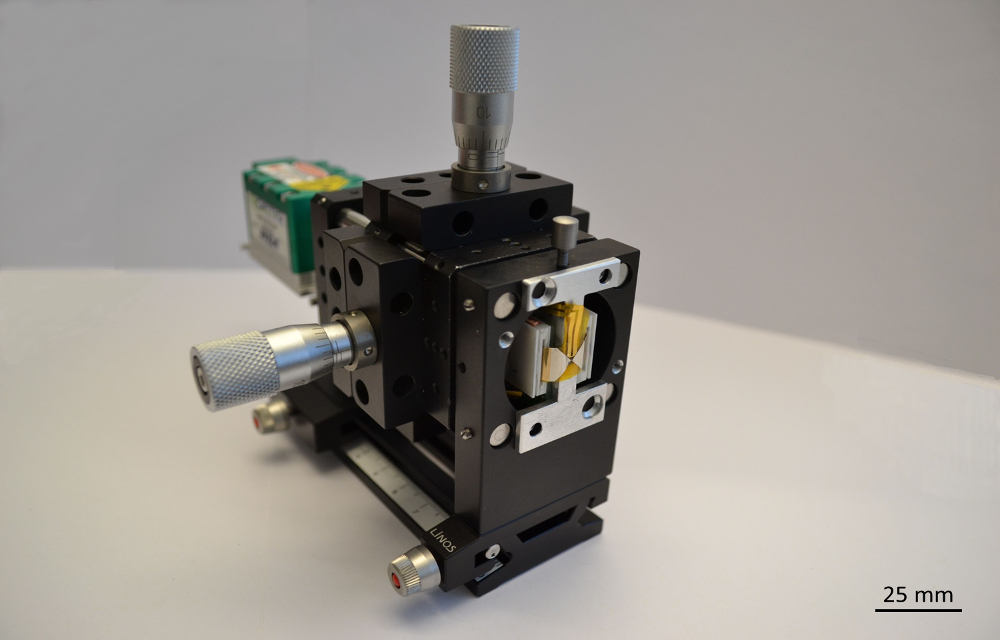

In this respect, IMPT developed a novel magnetic storage technology. The flexible write head remains operable, even if exposed to vibrations or dust particles. In contrast to conventional write heads, the novel one has a flexible magnetic core which is more robust against mechanical influences.

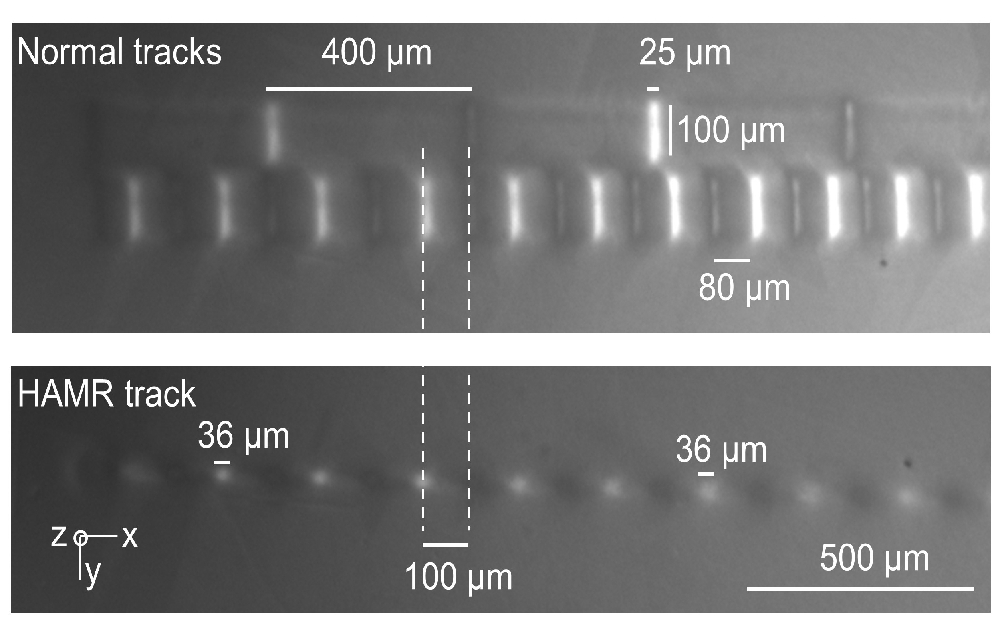

The coercivity enhances the stability of the stored data considerably. To develop an easily writable storage medium with high coercivity, the researchers used the effect of heat-assisted magnetic recording (HAMR). By using a laser beam heating the storage medium locally, the flexible write head achieves a storage density of up to 98 kbit per square centimetre.