Traditional data collection methods use radio frequency identification tags (RFID tags) or printed barcode labels. The disadvantage is that they do not withstand extreme heat or moisture. In future, data could be stored directly on the component surface: in extremely hard and highly resistant thermally sprayed coatings.

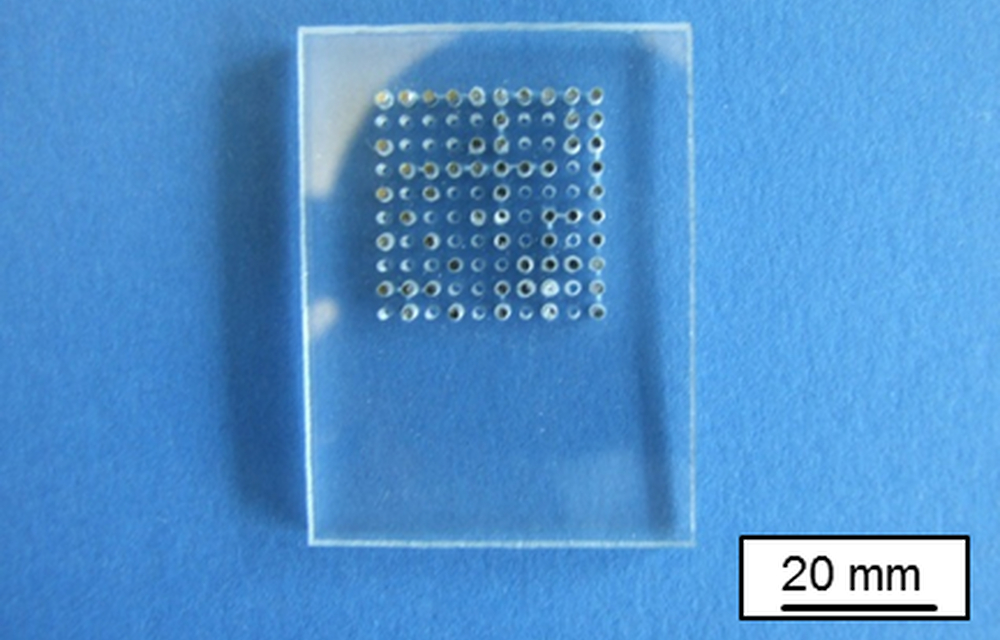

Powder used for thermal spraying often already contains magnetic particles. To verify their suitability for data storage, IW scientists applied coating to aluminium test samples. Tungsten carbide cobalt composite (WCCo) was used as spray powder material: a material utilized in industry for example for coating rollers in paper manufacture.

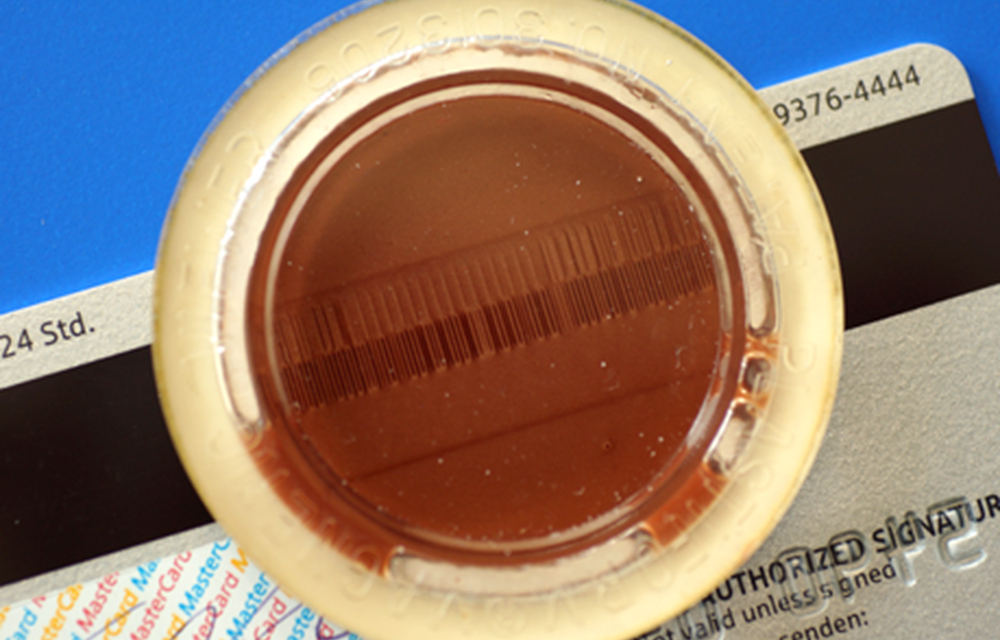

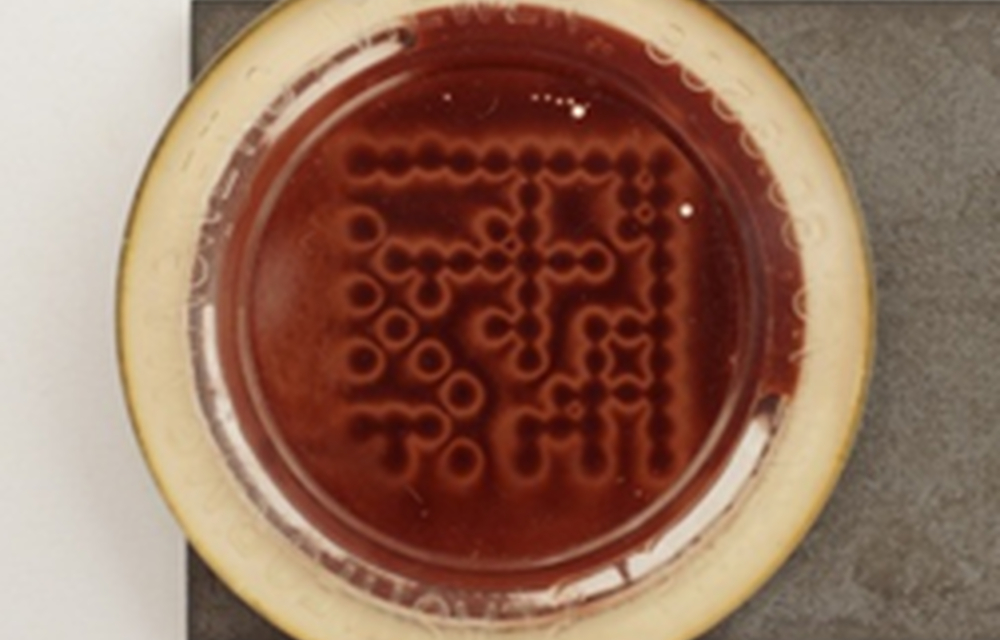

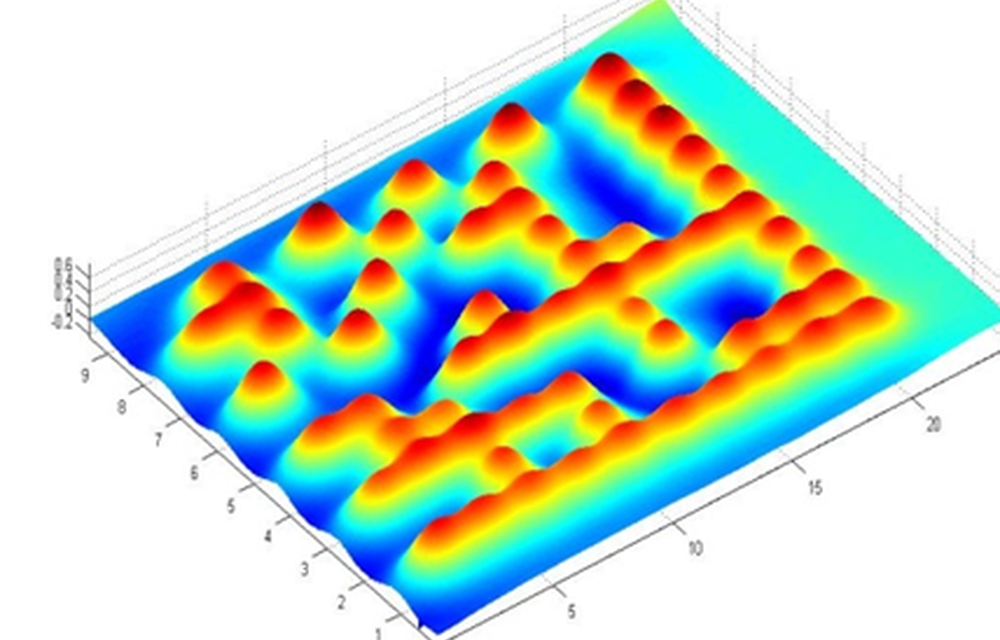

The WCCo coating was magnetized with permanent magnets and a magnetic pattern (see Figure 2). The researchers verified the result with a magnetic viewer, making the magnetic fields visible to the naked eye (see Figure 3).