The Institut für Integrierte Produktion Hannover (IPH) gGmbH wants to facilitate factory planning processes sustainable by using automatization and digitalization. Currently, scientists work in three different projects to re-organize the analysis, planning and evaluation of factories: A drone scans a factory building to acquire 3D-aerial images, which can be redesigned by the user. A software shall be able to redesign the factory layout automated. Another software already can calculate the efficiency of that redesigned factory. The developments will be presented at the Hannover Messe 2018.

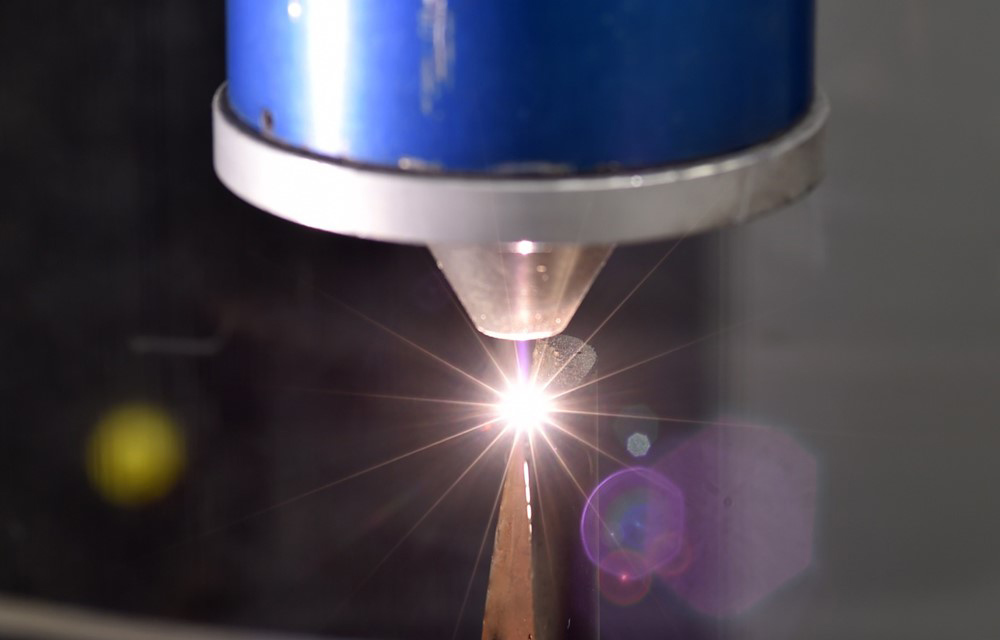

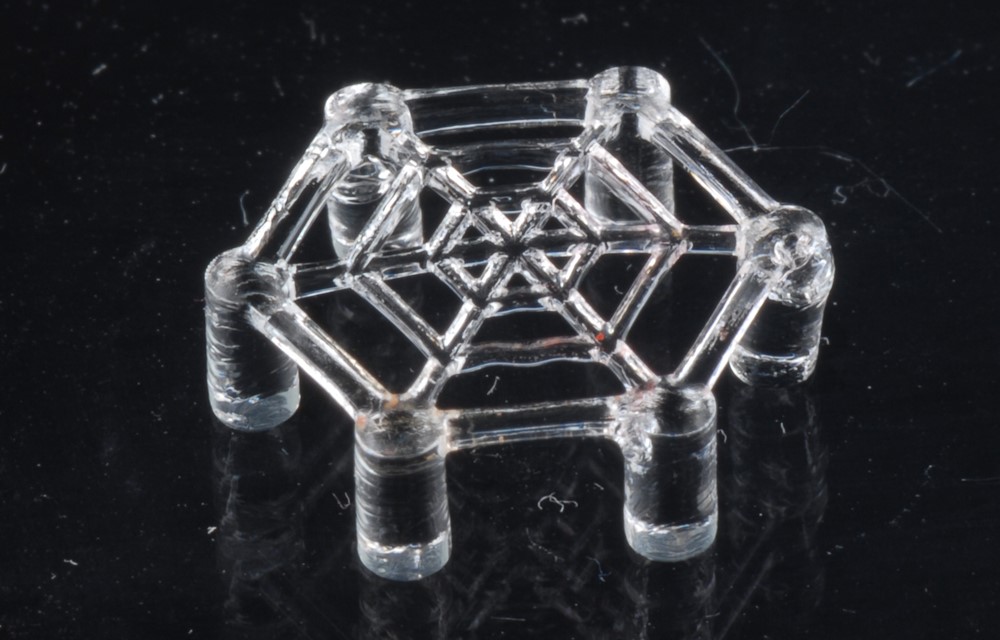

The LZH develops additive manufacturing processes with a special focus on multi-materials. With nozzle-based methods hardness gradients can be generated in a polymer component. This is interesting for in-ear hearing aids that should be soft on the outside but hard enough inside. And with laser deposition welding, for example, the LZH can apply large quantities of material to provide shafts with a protective layer.

In addition, the LZH will be showing the safe deflagration of unexploded bombs and new methods for laser material processing.

Small and medium-sized entreprises (SMEs) from Lower Saxony will find another competent partner for 3D printing at the Pavilion: Niedersachsen ADDITIV – Zentrum für Additive Fertigung. The center supports SMEs in introducing additive manufacturing technologies.