In the PhoenixD cluster of excellence, various manufacturing processes are combined to form a flexible, multi-modal optical production. Optical systems with various process modules such as flexography, laser glass deposition, laser structuring or ultra-precision machining are produced directly on a substrate.

A new type of actuator is used to guide and align the substrate with nanometer precision in relation to these process modules. At the same time, dynamic process forces must be absorbed without changing the orientation of the substrate. The actuator must therefore have a high dynamic stiffness. In addition, process data such as the resulting process forces and the position must be continuously determined. Manufacturing deviations can be determined from this process data information and compensated in subsequent manufacturing steps.

Dynamic, precise and sensitive

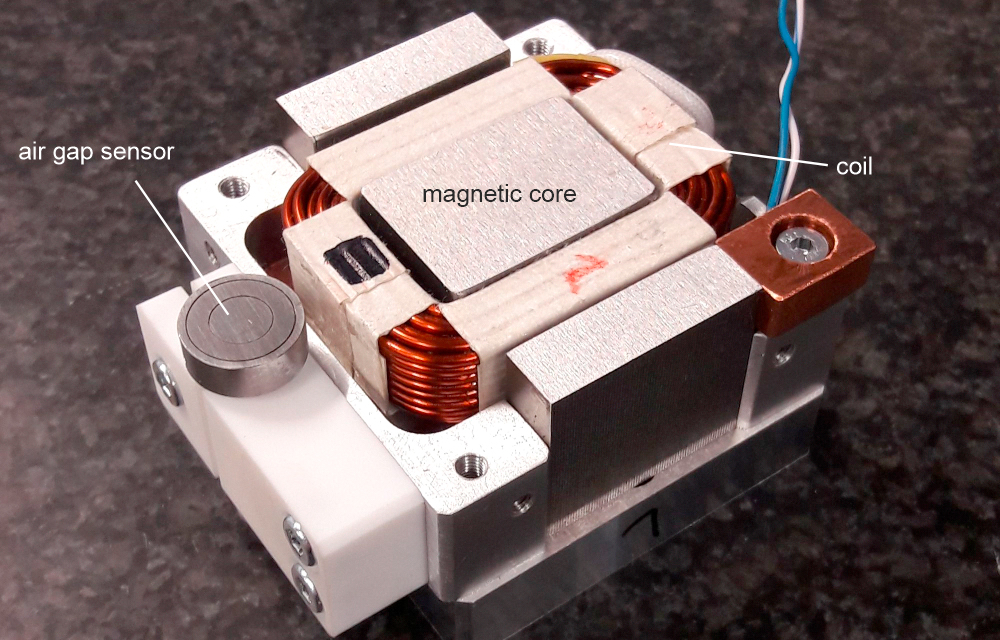

With the technologies used today, it is not possible to combine the required stiffness, dynamics and precision. Scientists at IFW are therefore researching active magnetic bearings that meet these requirements. An active magnetic bearing consists of two bearing halves separated by an air gap (see Figure 1). A coil through which current flows generates a magnetic field whose attraction force depends on the current intensity and the width of the air gap. The width of the air gap is measured with a sensor.

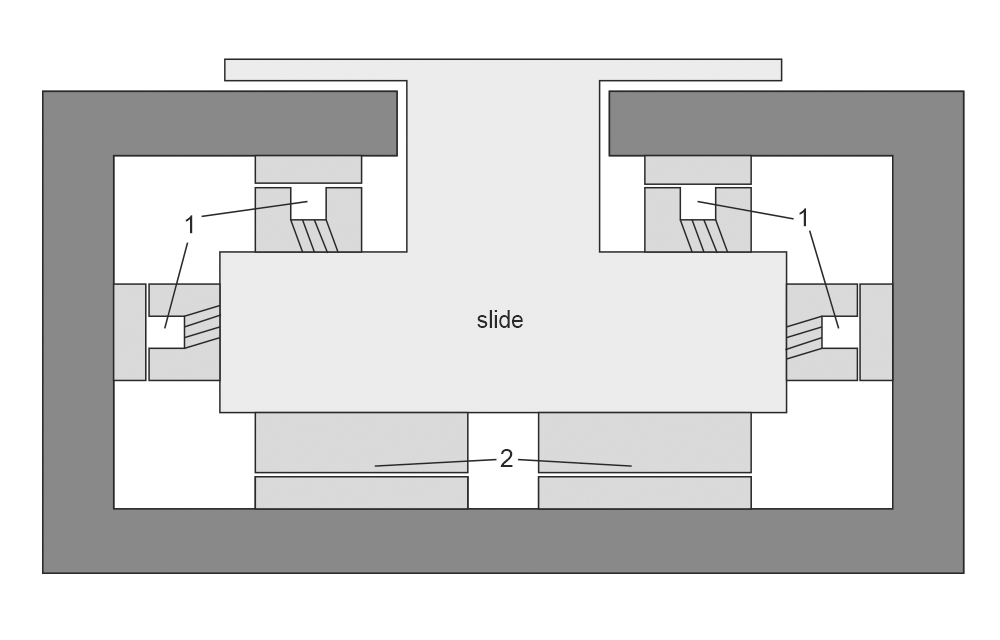

An actuator consists of several such magnetic bearings mounted on a movable carriage (see Figure 2). By adjusting the coil currents, the carriage can be levitated and can be finely positioned with high accuracy in five degrees of freedom without contact. In addition, a linear direct drive enables movements with long travel (sixth degree of freedom). In a model-based approach, position and orientation of the carriage can be determined from the measured air gap widths. Furthermore, the forces acting in all spatial directions can be calculated from the known coil currents via the magnetic characteristic curve without the need for additional sensors. Since the sensor data can be used to precisely record the status of the actuator, this is referred to as "sensitive".

Effective movement and fine positioning

In their previous research work on active magnetic bearings, the scientists at IFW have also identified challenges. For example, there is a non-linear relationship between air gap width, coil current and attraction force. Furthermore, the dynamic stiffness is strongly limited by the latency of the digital controllers used. At IFW novel control concepts are therefore investigated on a rapid control prototyping system. Thus, latency can be significantly reduced and dynamic stiffness can be increased.

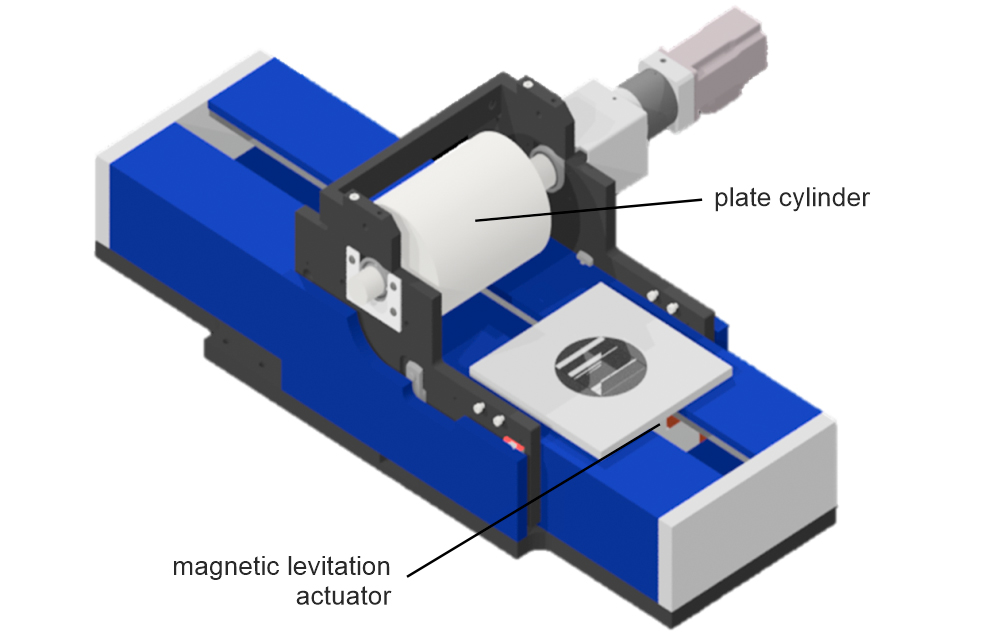

In order to evaluate the actuator, it is built into a process demonstrator for a flexographic printing process (see Figure 3). Here, the actuator can not only perform the linear active movement between the substrate and the plate cylinder, but also precisely align the substrate in all spatial directions. Furthermore, the contact pressure between substrate and plate cylinder can be adjusted dynamically during the process, thus achieving a reproducible print image.

Within the PhoenixD Cluster of Excellence, the actuator is subsequently to be used in other processes as well – for example in laser structuring.