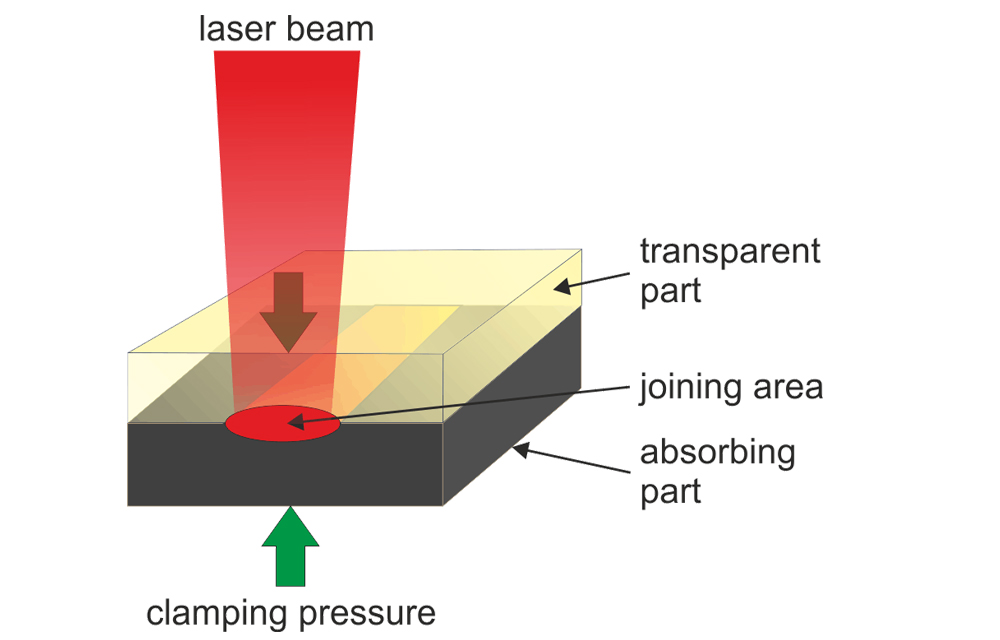

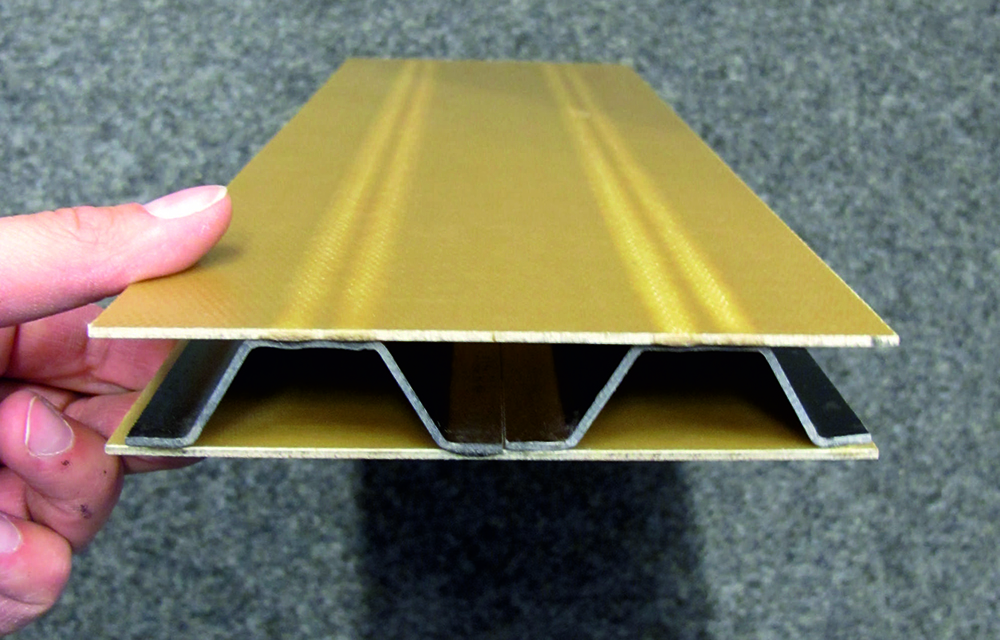

Within the scope of the European Eurostars project LaWocs, new laser-based welding processes for the joining of thermoplastic fiber composite parts have been developed. Worldwide new lightweight constructions are a key issue of the mobility sector. They shall enable weight reductions in both aviation and automotive industry as well as in ship building.

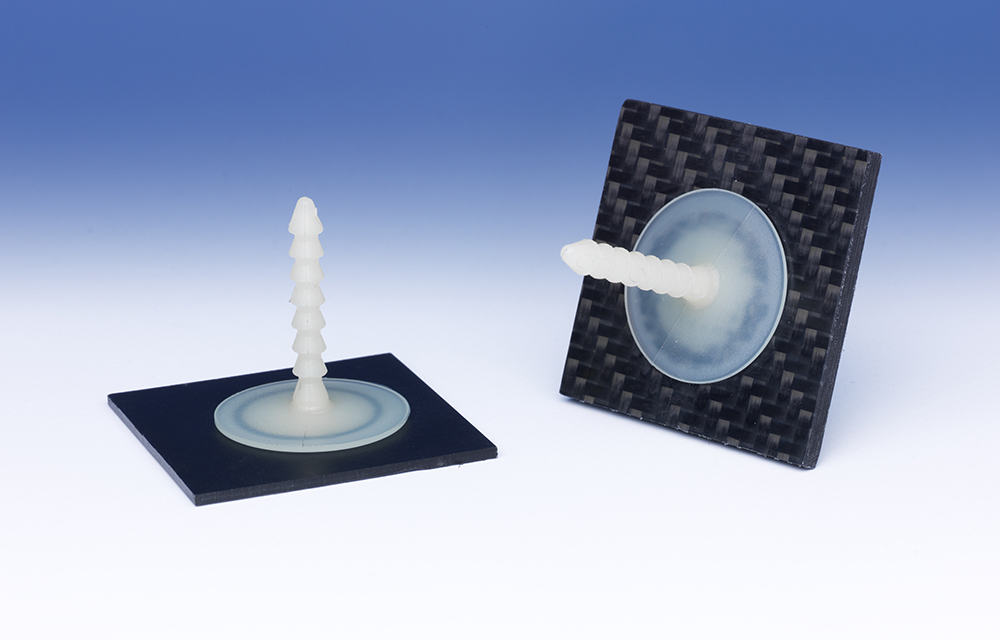

As a result of the international cooperation of several partners, LaWocs makes it possible for the first time to integrate and optimize all sub processes of the material and process development as well as of the production and testing of the part. Several demonstrators were successfully realized with the new joining technique. Analyses show that the parts have improved properties compared to those joined by gluing.