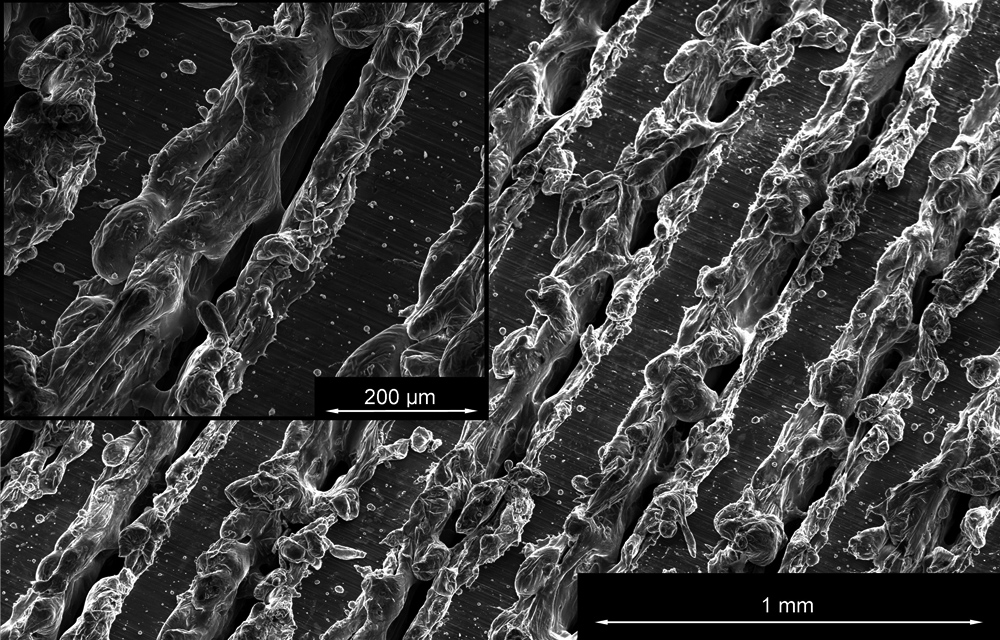

The textile part to be joined is a thermoplastic, nonwoven fabric with polyester fibers with a low melting temperature. First, a solid-state laser roughens the surface of the metal sheet. Then the metal sheet is heated and joined to the textile material. The thermal energy melts the polyester fibers, allowing for a hybrid connection between the metal and the textile.

This joint provides a much higher adhesive strength than conventional bonding using adhesives. However, the process is currently still in the trial stage. Ultimately, the project partners plan on structuring the sheet metal directly from the coil using the laser.