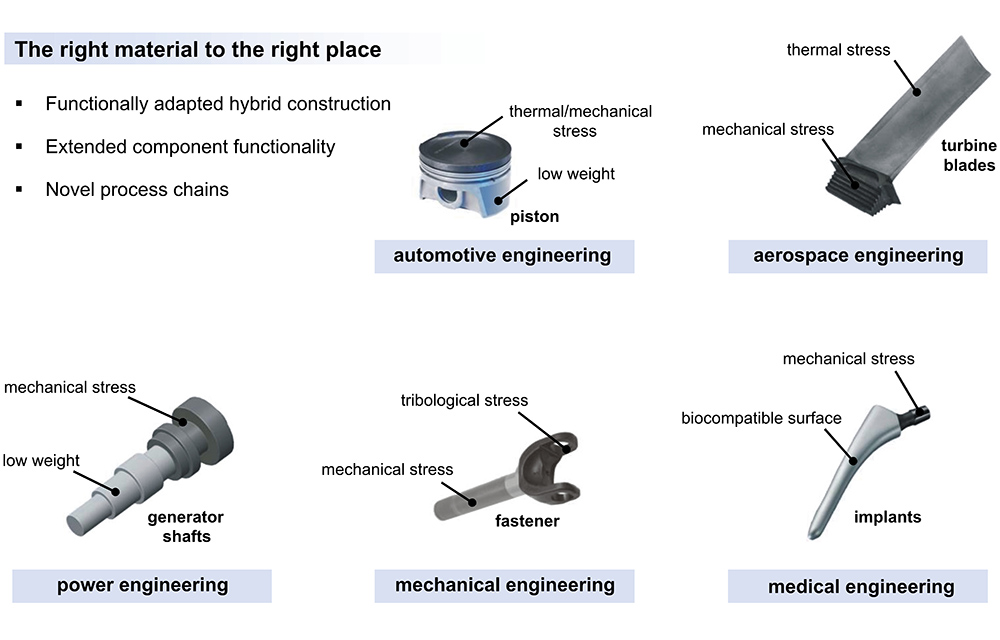

The Collaborative Research Centre (CRC) focuses on “Tailored Forming“: Hybrid workpiece made of different materials – for example, high strength steel and light aluminum – shall be formed in one step. This enables the manufacturing of solid high-performance components with properties that are specifically tailored to the respective field of application. Possible applications range from turbine blades over generator shafts to implants (Figure 2).

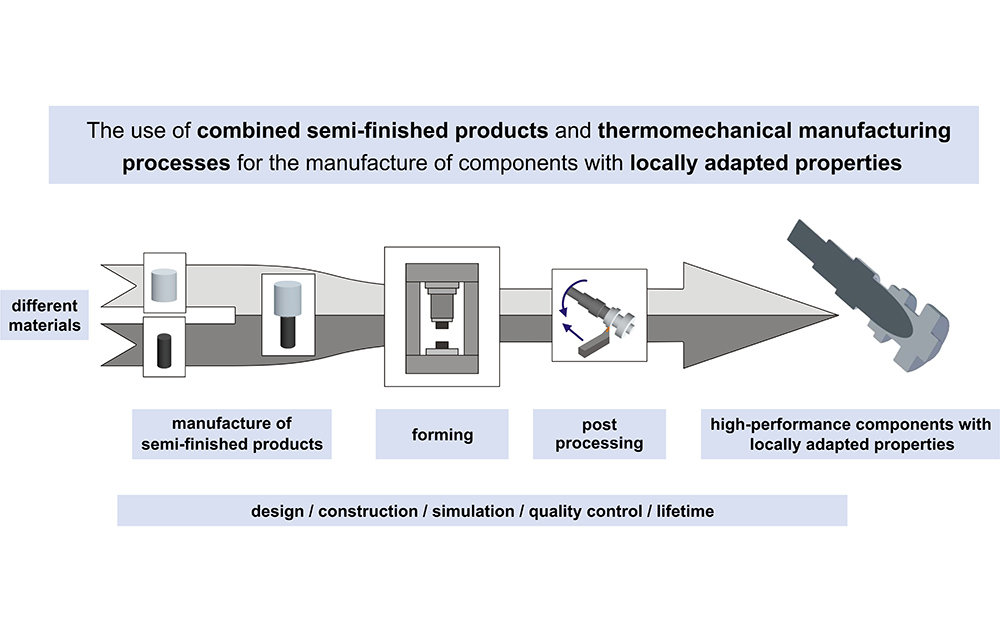

Around 40 scientists from ten institutes are jointly working at the CRC. Divided into subprojects, they are dealing, among others, with laser welding and cross wedge rolling of hybrid workpiece, but also with process planning and the prediction of failure. Their common goal is to develop a novel process chain (Figure 3). For this purpose, two different materials are bonded to obtain a hybrid workpiece. Then, the hybrid is formed and machined in the following steps.