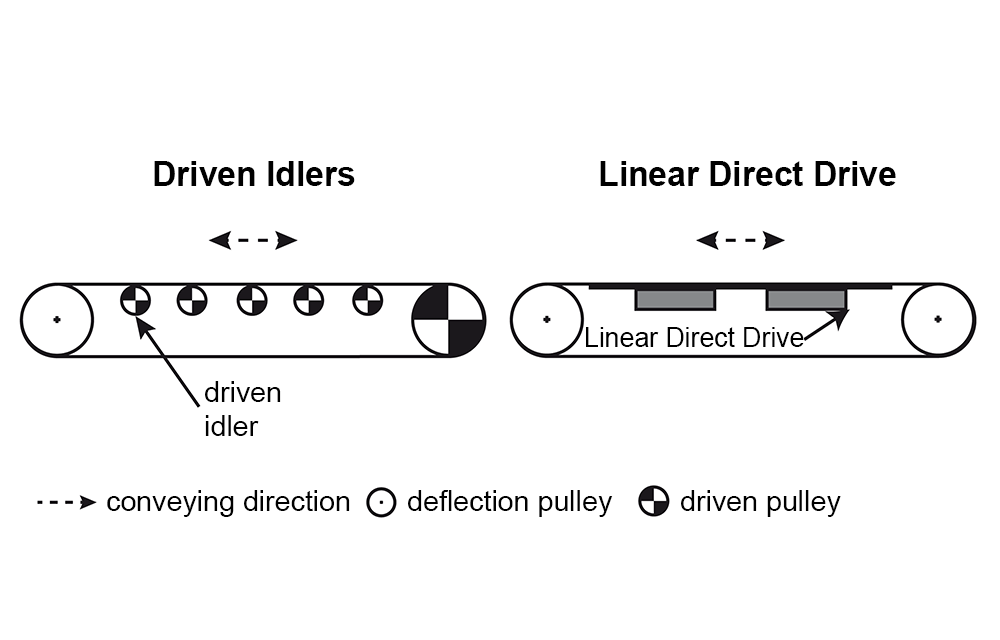

Whether in dispatch warehouses or in production: Conveyor belts have to transport more and more goods over increasingly longer distances. For this reason, the Institute of Transport and Automation Technology (ITA) and the Institute for Drive Systems and Power Electronics (IAL) are jointly working on alternative drive concepts (see Fig. 2).

In linear drives, feeding force is directly induced by the electromagnetic field. Thus, the belt tension and the belt stress from the motional resistance can be reduced significantly compared to conventional drives. In intralogistics, linear synchronous motors are already in use, for example in sorting systems – in contrast, for today’s belt conveyors this drive principle is not applied, yet.

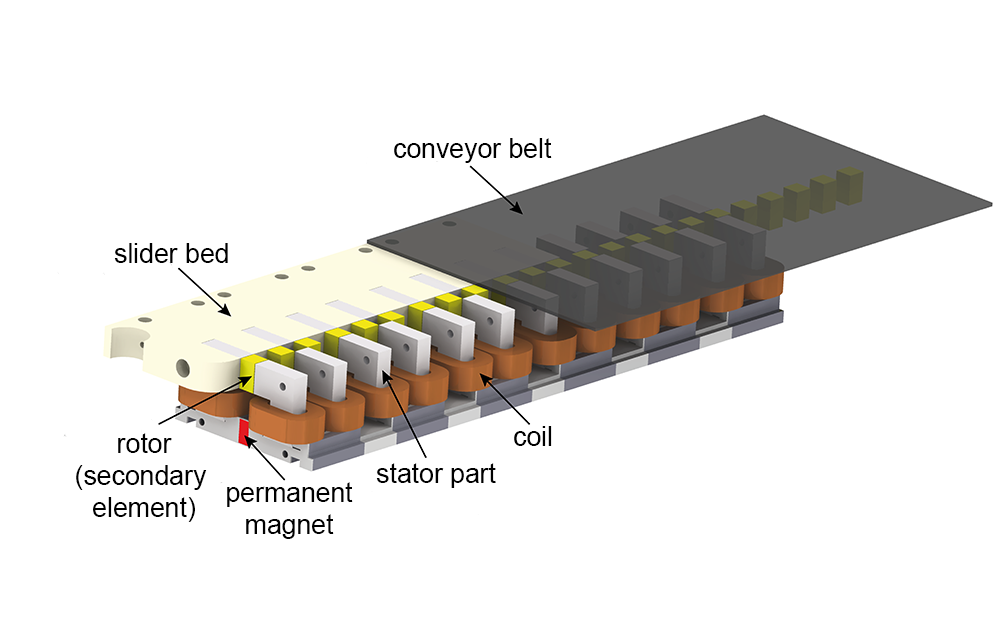

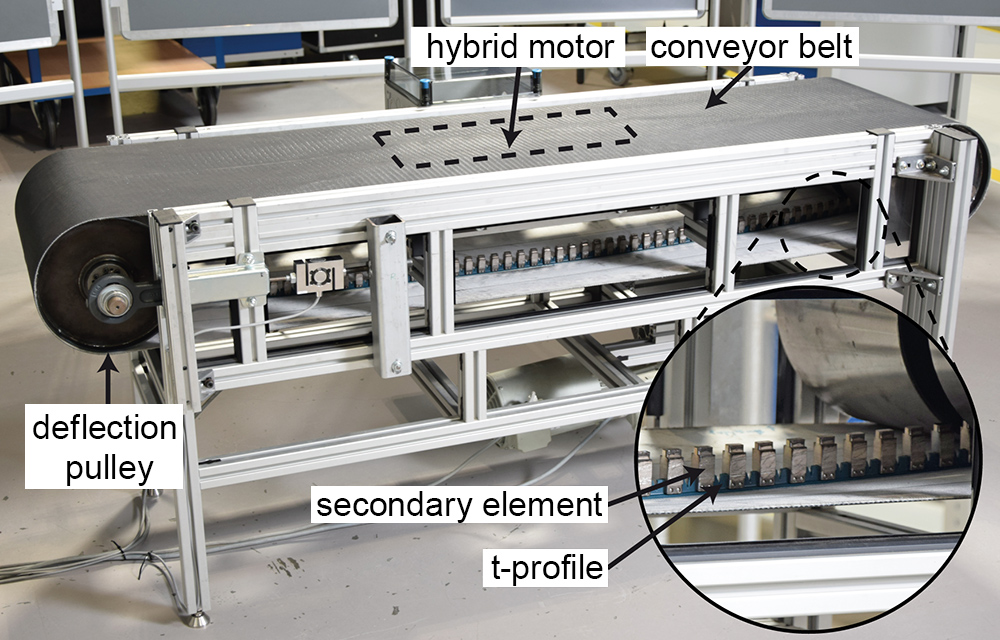

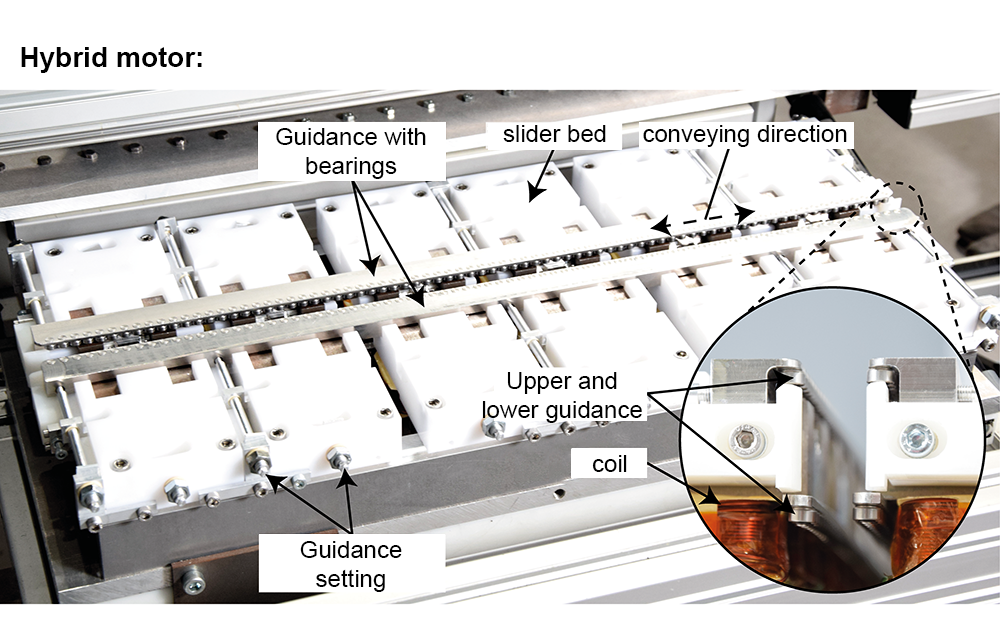

Considering conventional flexible conveyor belts, the researchers pursue the principle of a hybrid motor (see Fig. 3). Combined with integrated permanent magnets, the excited stator induces a changing electric field. That way, the secondary elements are moved. They are made of magnetically soft material and are mounted to the conveyor belt. Based on this principle, the researchers developed a demonstrator (see Fig. 4). In the next step, they want to validate their development by experiments and compare it with conventional belt conveyors.