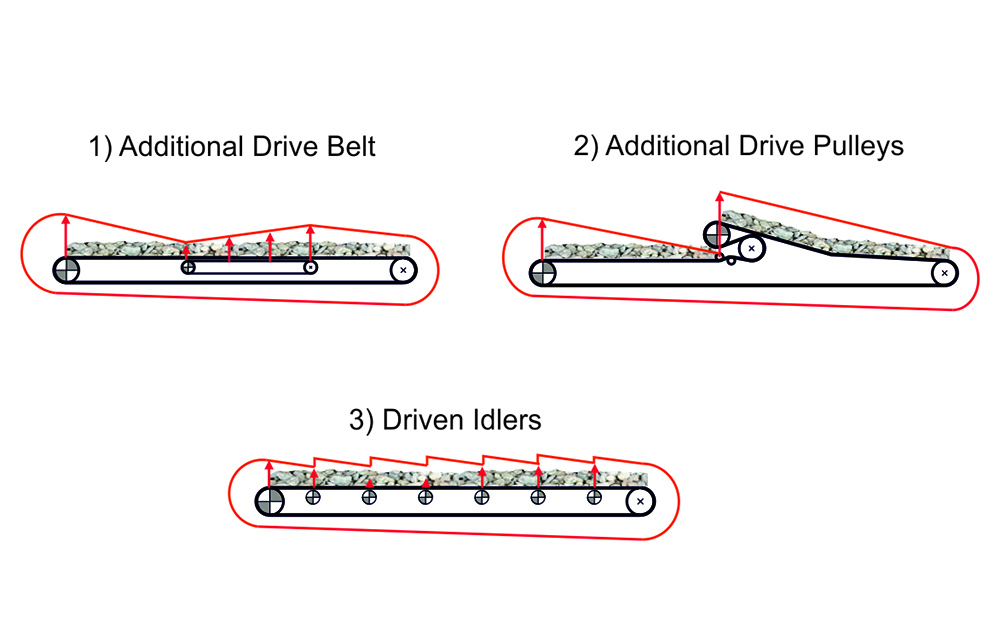

Belt conveyors are used for the transport of enormous quantities of ore or gravel over distances of up to 20 kilometres. Longer conveying distances can only be realized when using additional drives (see Fig. 2), e.g. drive belts or drive pulleys. However, this goes along with high investment cost or requires extra transfer points, putting more strain on the conveyor belt.

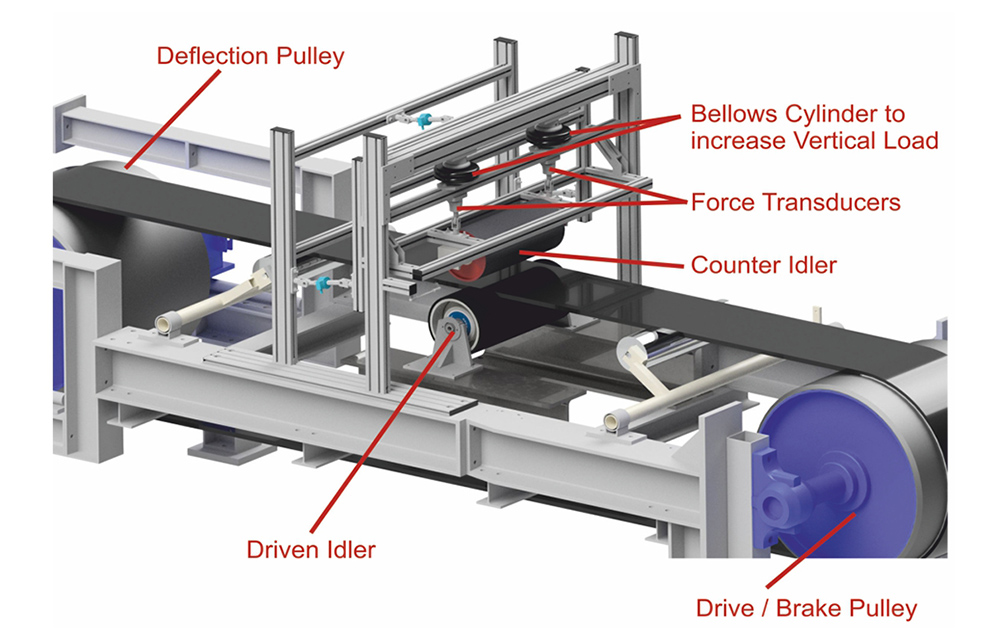

At present, researchers of the Institute of Transport and Automation Technology (ITA) of Leibniz Universität Hannover are investigating the potential of driven idlers. Belt conveying systems consist of many hundreds of idlers which bear the weight of the conveyor belt and the bulk material. The idea is that part of the idlers is driven by a motor to reach a more evenly distributed transmission of force (Fig. 2).

Provided that the use of driven idlers becomes accepted in conveying technology, this could enable transports over considerably longer distances. In this way, even upcountry pit mines could be connected economically to a port.