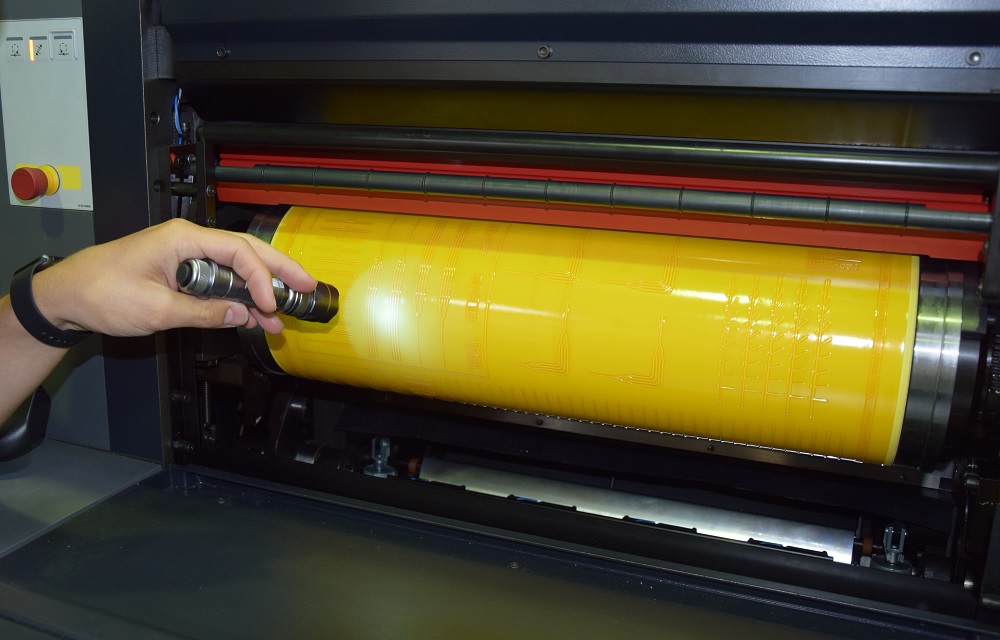

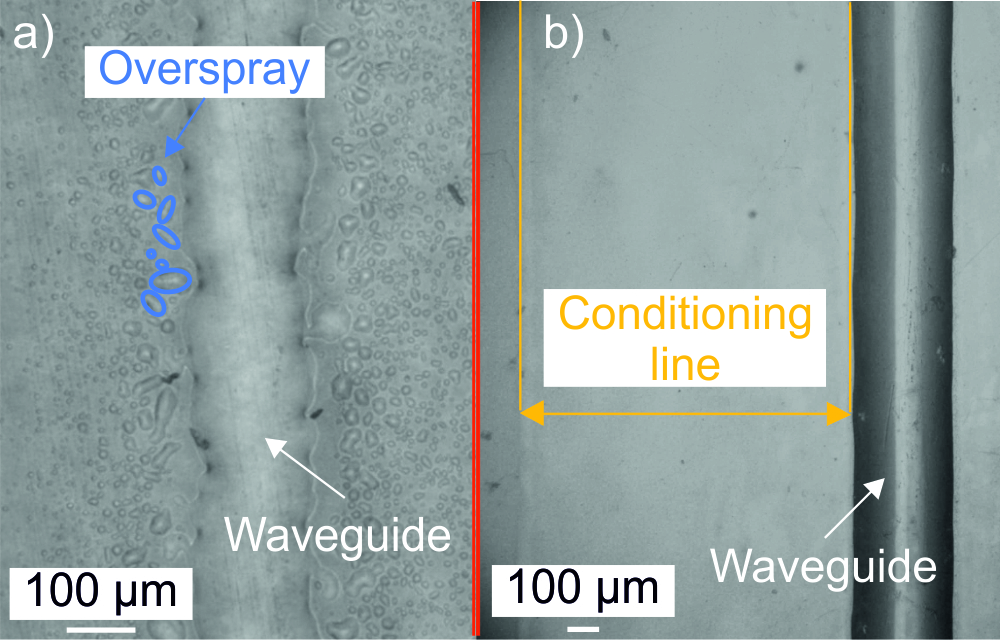

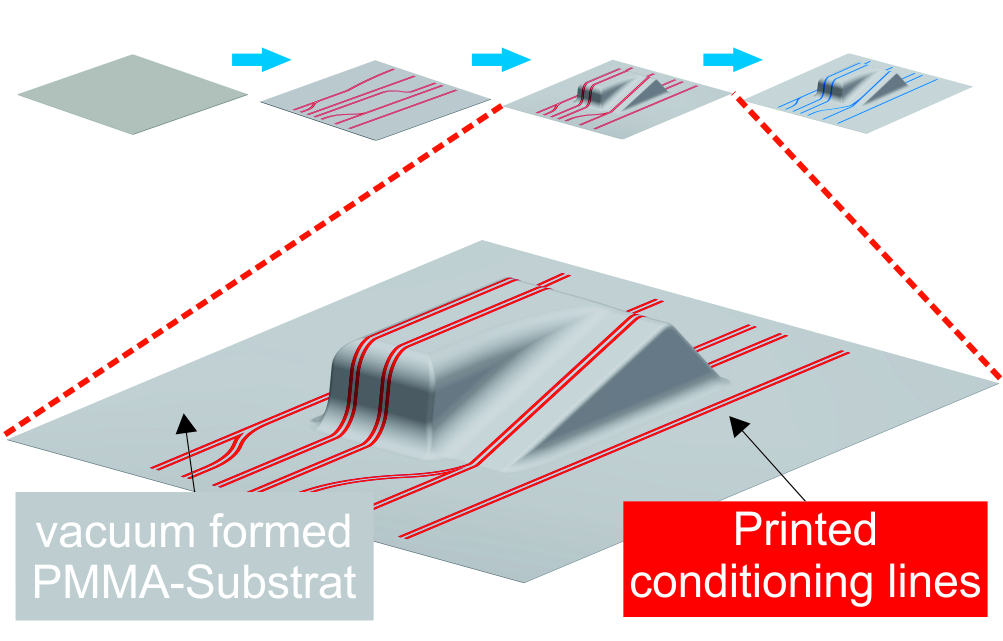

In the research group Optical Assembly and Connection Technology for Optical Bus Systems (OPTAVER), researchers of the Institute of Transport and Automation Technology (ITA) are investigating the printing process for optical networks using an industrial printing machine. In cooperation with the Laser Zentrum Hannover e.V. (LZH), they want to adapt their research results for an application on three-dimensional objects: The optical waveguides that are printed on foils are formed by a thermoforming machine for three-dimensional circuit carriers.

The researchers want to realize bandwidths which can supply an aeroplane with more than 300 passengers with a 4K video signal. To realize this large amount of data, they want to integrate the polymer optical waveguides (POW) into the later component. The POWs are formed by heating the foil with the printed waveguides in a thermoforming machine to forming temperature and by forming it by a vacuum into the later shape.