Aluminum engines have a much lower weight than their cast iron predecessors. In Otto engines, however, the cylinder inner surfaces must be lined with steel or gray cast iron bushings. Aluminum has a lower strength and hardness than steel or cast iron. Without steel coatings, the surfaces would have too low a strength.

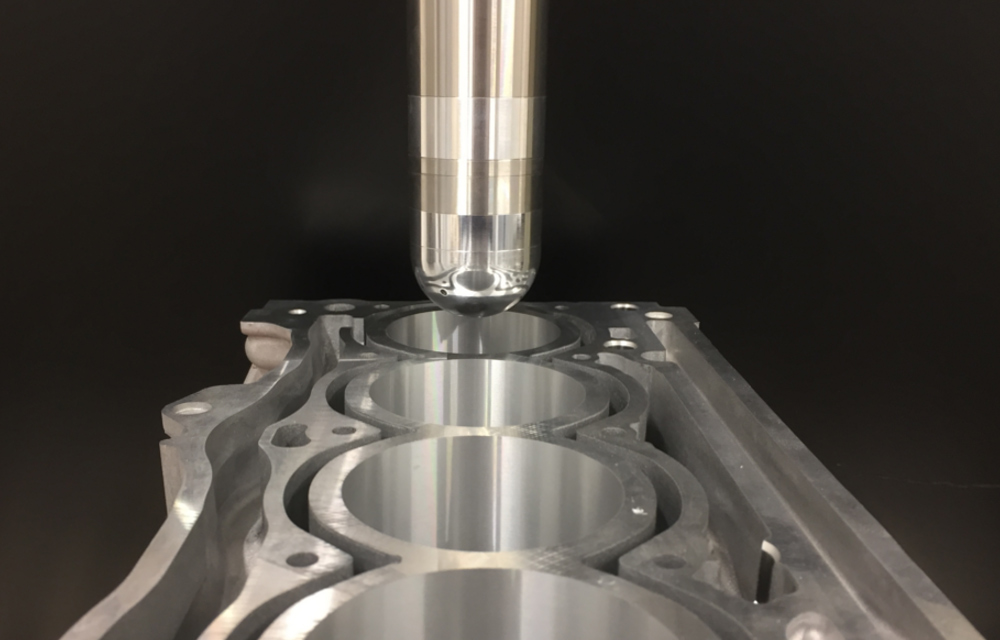

In Otto engines the Volkswagen AG inserts a thin steel layer into the cylinder bore. This makes it possible to arrange the cylinders closer and to build more compact engines.

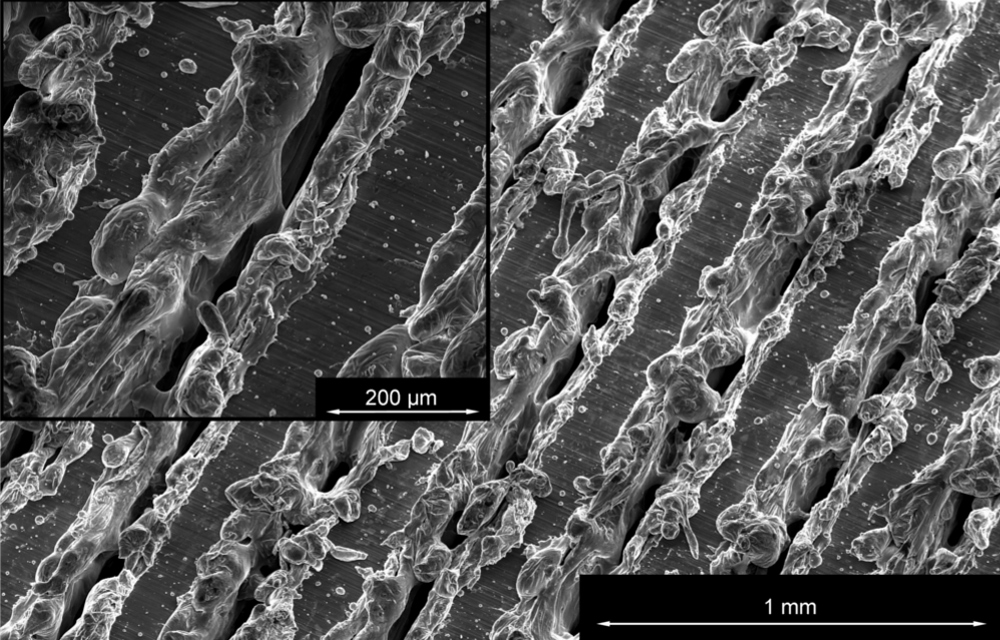

To ensure that the steel layer adheres firmly to the aluminum, the inner surface of the cylinder is roughened before coating. This has hitherto been carried out using machining processes that cause high tool wear, or using corundum blasting. Therefore, the Laser Zentrum Hannover e.V. (LZH) and their partners developed a laser-based roughening process. Laser processing heads do not wear out thanks to contactless processing.

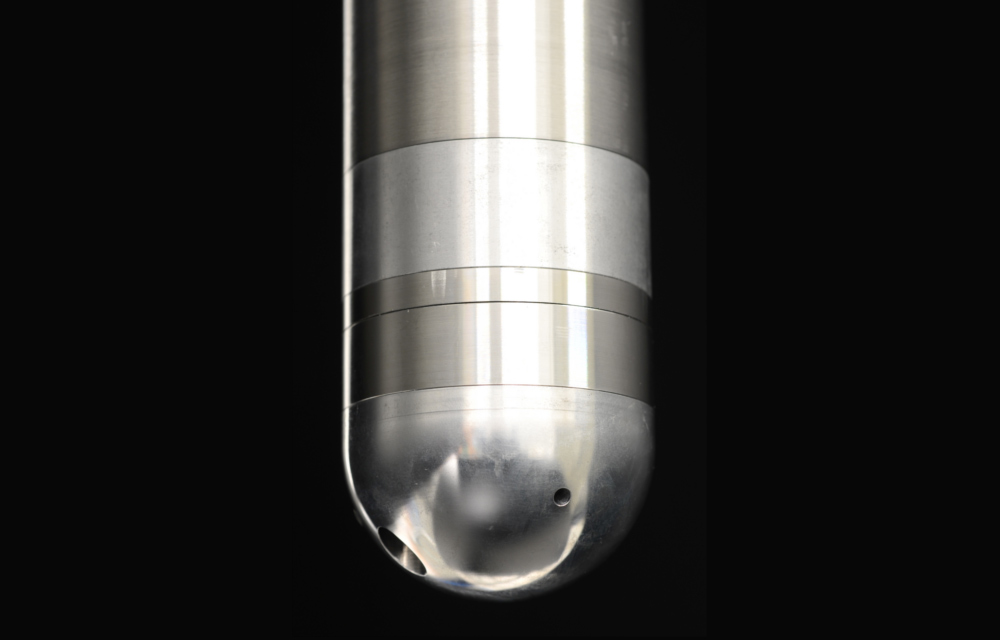

The LZH has recently finished the second, even more powerful and easy-to-maintain generation of laser processing heads.