FRPs have both high strength and stiffness. However, defects or damaged areas in FRPs must be repaired with completely different processes than those used for metal construction. In the projects ForLase and ReWork, the LZH is working on removing defects quickly, cost-efficiently and reliably.

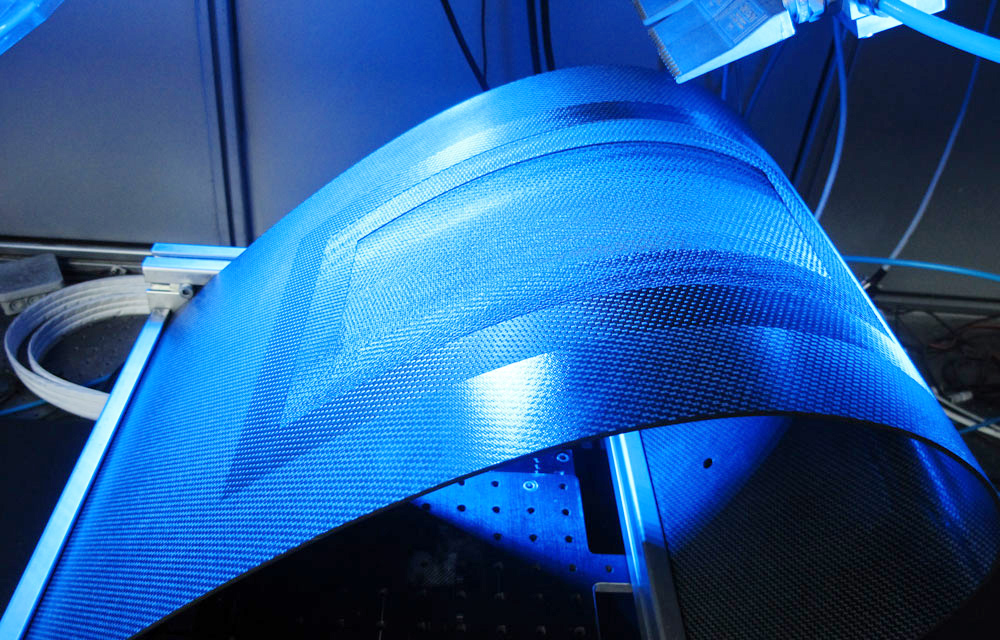

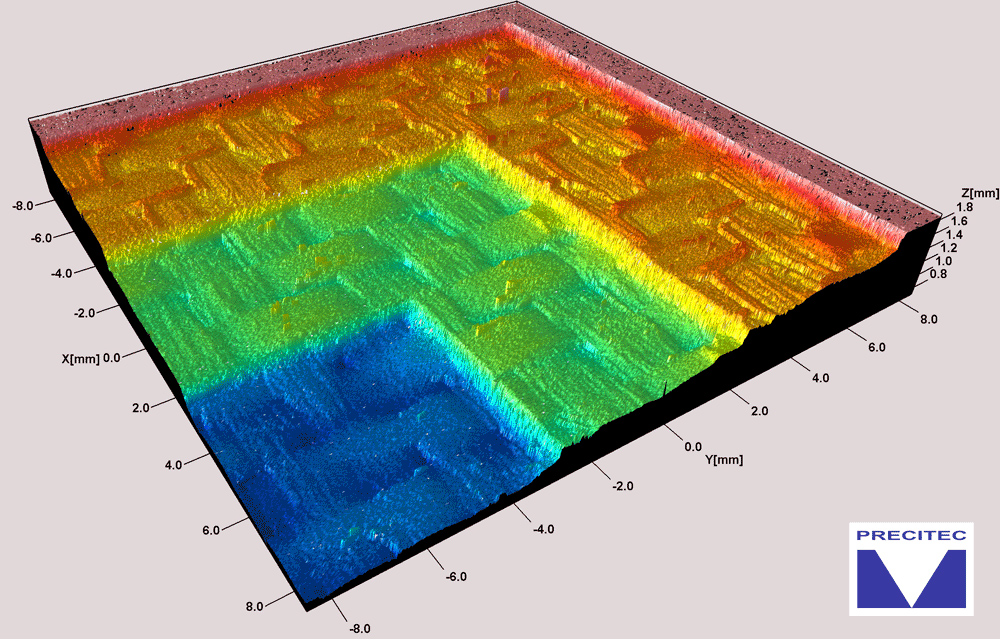

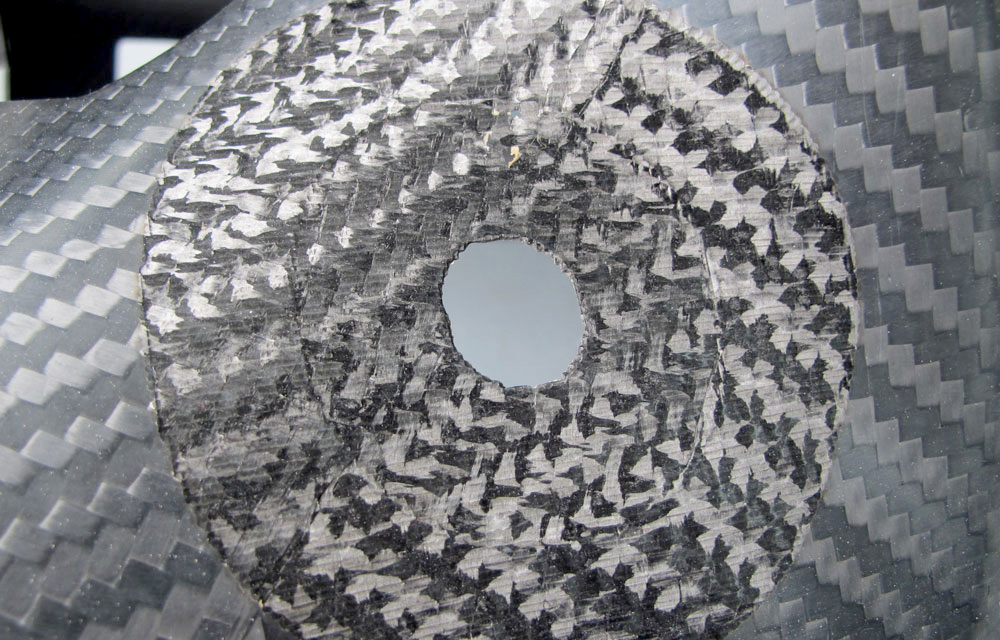

In the joint research project ReWork, the LZH is developing a repair process for thin-walled and complex components made of carbon fiber reinforced plastic (CFRP) – together with the companies INVENT GmbH, OWITA GmbH and Precitec Optronik GmbH. Their goal: Removal of the defective area using a process called scarfing, and subsequently precisely connecting the replacement parts, the so-called patches. A laser and a short coherence interferometry system are used for precision removal of the damaged layers. The goal is to achieve a predefined scarfing geometry, so that the composite material can be repaired on a high quality level.

In the research project ForLase, the LZH is working together with Apodius GmbH to combine an innovative measurement unit for determining the fiber position orientation with a laser-based repair process. The optical system recognizes the fiber orientation of the exposed material, and can thus determine whether a layer has been completely removed.