Textiles represent an important material in various aspects of our daily life: clothing, sports and leisure, building and construction, aerospace, automotive, civil engineering, household, fishing, architecture, etc. Especially, clothing textiles play an important role in human society. To best satisfy the customers, nowadays the clothing is offered in diverse designs, functions, colors, shapes, sizes and in a broad price spectrum. To fulfill these requirements, the textile industry continuously develops new products composing of diverse constituents like mixed fabrics including natural and/or synthetic fibers as well as specially coated fibers, diverse functional and decorating articles like zips, buttons, patches, etc. More than half of the worldwide produced fibers are polyester fibers, which represent a synthetic thermoplastic material. At the same time, the textile performance focused only on the useful phase of the textile products with the continuously changing wide range of textile compositions complicates their effective and efficient recycling.

Tons of textile waste

In 2018 textile waste amount was 2,170,000 tons in EU and 338,342 tons in Germany (Eurostat). Due to the growing environmental and legal consciousness, in future also the recyclability of the waste and worn-out textiles will play an important role in the textile industry. Particularly, according to the European Waste Frame Directive starting by January 1, 2025 textile waste has to be collected separately. Furthermore, EU announced development of a comprehensive strategy for textiles including measures to stimulate the market for sustainable and circular textiles in the EU. Already existing measures typically include resale second-hand textile market or downcycling i.e., reprocessing into lower value products like cleaning rags. According to the Centre for the Promotion of Imports from developing countries (CBI), approximately 50% of the old textiles in Germany are sold as second-hand articles worldwide and 21 % are used for the production of new cleaning cloths.

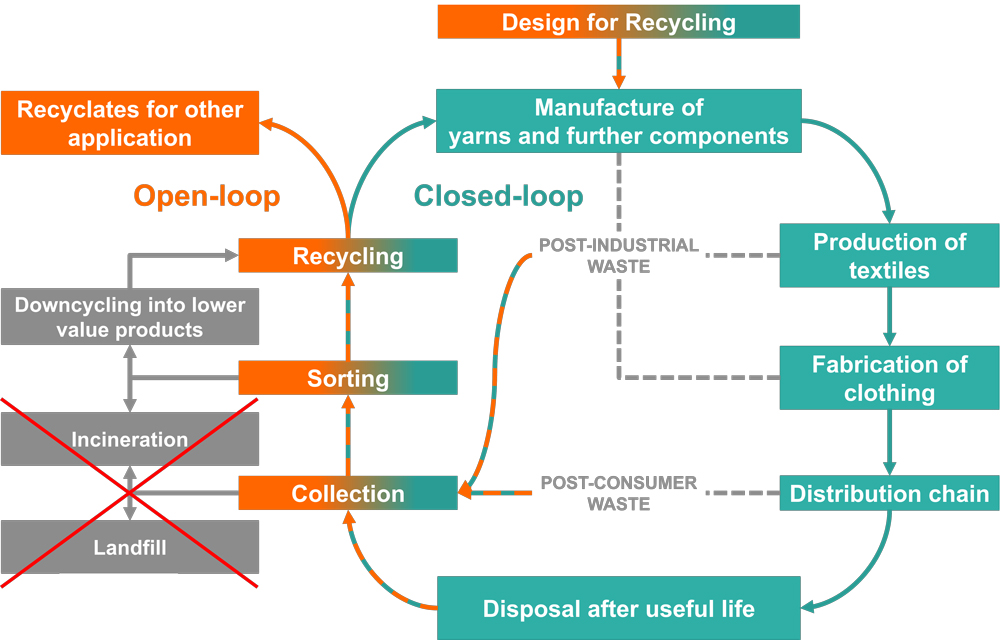

Nevertheless, at a certain point a further resale or reprocessing of textile articles is not possible and they are disposed as a waste. The regional waste collection systems strongly differ according to the legal and social attitude as well as technological possibilities. In general, currently, most of the textile waste is incinerated or landfilled, since there is no technologically feasible industrial recycling solution, which can address such high amount of the waste material. Worldwide only 1 % of the textile waste from the clothing industry is subjected to a closed-loop recycling i.e., the recycled components are used for the manufacture of new clothes.

Design for recycling of textiles

At the same time, an effective and efficient recycling of textiles would result in a high amount of recyclates, which could reduce the amount of virgin materials in some applications and lower the environmental impact of the textile waste. Closed-loop recycling presumes a so-called fiber to fiber recycling, while open-loop recycling enables use of the recyclates in other applications like injection moulded parts. A global holistic approach including a close cooperation of the government, industry and academia is required to optimise the existing value-added chain and enable sustainable design of products, universal collection and sorting systems for post-industrial and post-consumer textile waste as well as development and implementation of innovative recycling technologies.

Particularly, the recyclability of textiles should be considered already before manufacture of the fabrics and clothing articles. Consequently, the design for fashion should be extended to cover not only consumer needs and desires but also requirements for effective recycling i.e., design for recycling. Furthermore, textile industry is associated with a large amount of post-industrial textile waste generated during manufacture of yarns, especially synthetic yarns, production and fabrication of the fabrics and resulting clothing articles. Due to climatic and economic reasons, various components and semi-finished products are manufactured in different regions. Consequently, if the regional collection and recycling systems are not suitable for the treatment of the textile waste, the high transport costs make recycling uneconomic.

High-quality mechanical recycling

The mechanical recycling process, developed at the IKK, is a promising solution for recycling of various types of textile waste. Basically, during this innovative process meltable components of textiles are treated like a thermoplastic material. Initially, the sorted post-industrial or post-consumer textile waste is shredded, pelletized and processed using a cascade filter-based recycling extrusion to produce recycled thermoplastic granulates. The process parameters can be optimised depending on the art, type and content of the meltable and non-meltable components and their mixture. The quality of these recyclates can be improved according to the requirements of the further processing steps and application field using various additives like virgin plastics, fillers, reinforcement, coupling agents, color masterbatches, impact modifiers, etc. These recyclates can be used for the manufacture of various injection moulded parts.

The advantages of this approach include its suitability for high amount of input materials, decentral implementation and modularity of the processing steps. At the same time, the quality of the output stream strongly depends on the input stream i.e., pre-treated materials subjected to recycling extrusion. Further research activities are required to optimise the individual pre-treatment and processing steps to completely avoid landfill waste and, if possible, incineration. To realise the full potential of this technology, the IKK in close cooperation with brand owners and plant manufacturers carries out research on adaptation of the cascade filter-based recycling extrusion to manufacture high-quality recyclates.