Hybrid materials for lightweight construction like fibre-reinforced plastics consist of a mix of materials with widely varying properties. It’s a real challenge to simulate these materials numerically.

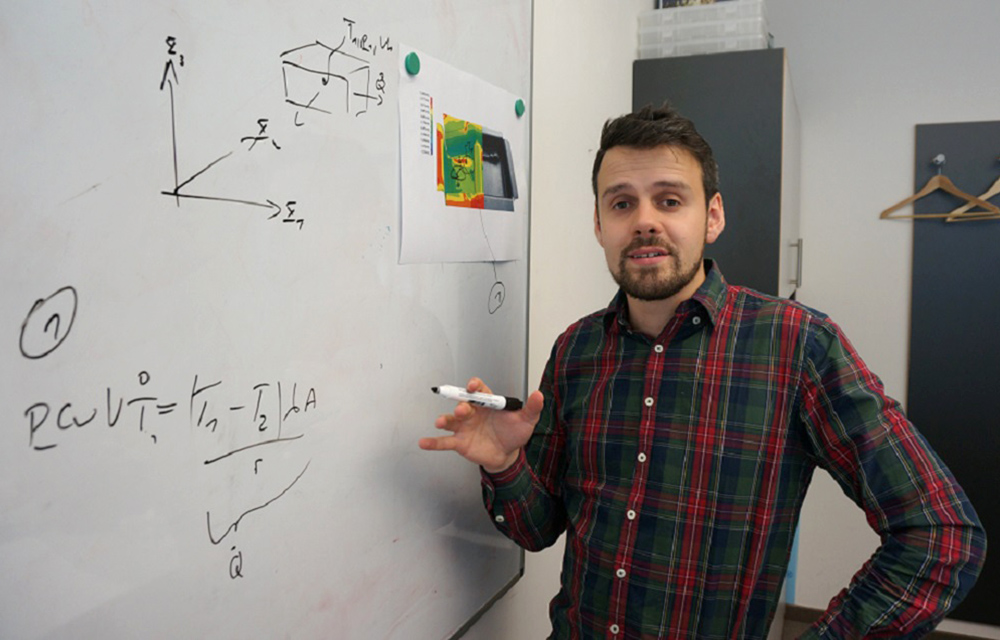

Within the framework of the joint research project ProVorPlus, the Institute of Forming Technology and Machines (IFUM) is developing appropriate simulation methods. Within the project, several institutes are collaborating with industrial partners in order to develop a production process for the lightweight construction of a battery tray made of organic sheets. Organic sheets are fibre-reinforced plastics: They consist of a fibre composite embedded in a thermoplastic matrix.

For modelling the production process numerically, the first step is to create a material model which combines the fibre composite’s properties with those of the thermoplastic matrix. Based on such a model, it is possible to develop new simulation methods. The result will be an efficient process design for the production of fibre-reinforced plastics and large-scale production of lightweight components in the future.