Lightweight construction plays an important role in automotive and aerospace industry. In cooperation with the Institute of Welding and Machining (ISAF) of TU Clausthal, the Institut für Integrierte Produktion Hannover (IPH) gGmbH is doing research on how to create a material bond between aluminium studs and steel sheets — combining material and structure lightweight design. Solid materials are used to withstand higher stresses, lightweight and less solid materials are employed in areas where lower stresses are expected.

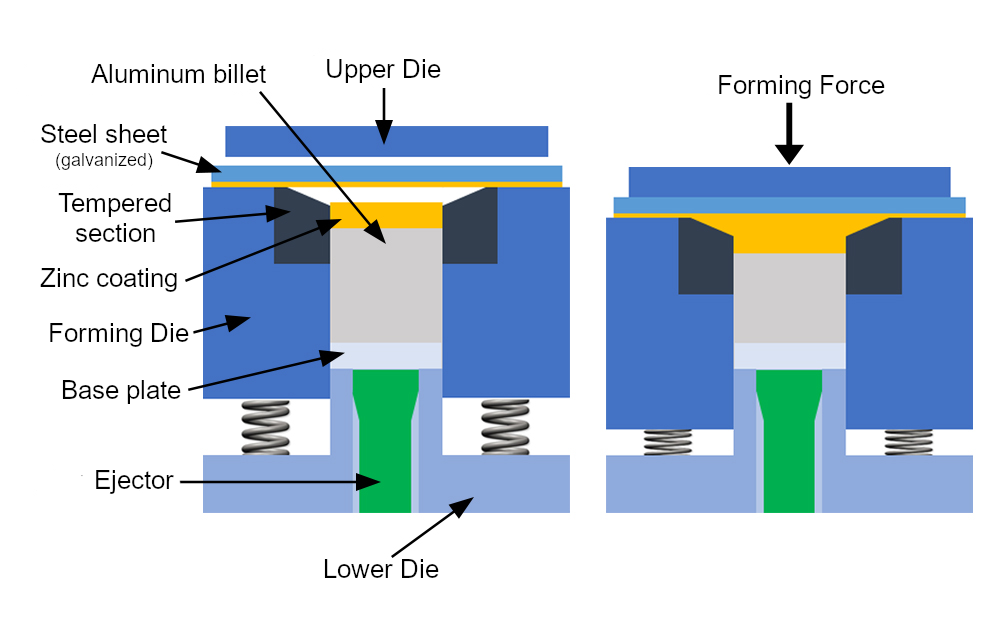

The material bond between the two joining partners is created in a forming process. To determine the appropriate joining parameters, the researchers are investigating different temperature ranges (100 to 360 degree Celsius) and forming speeds (50 to 460 millimetres per second).