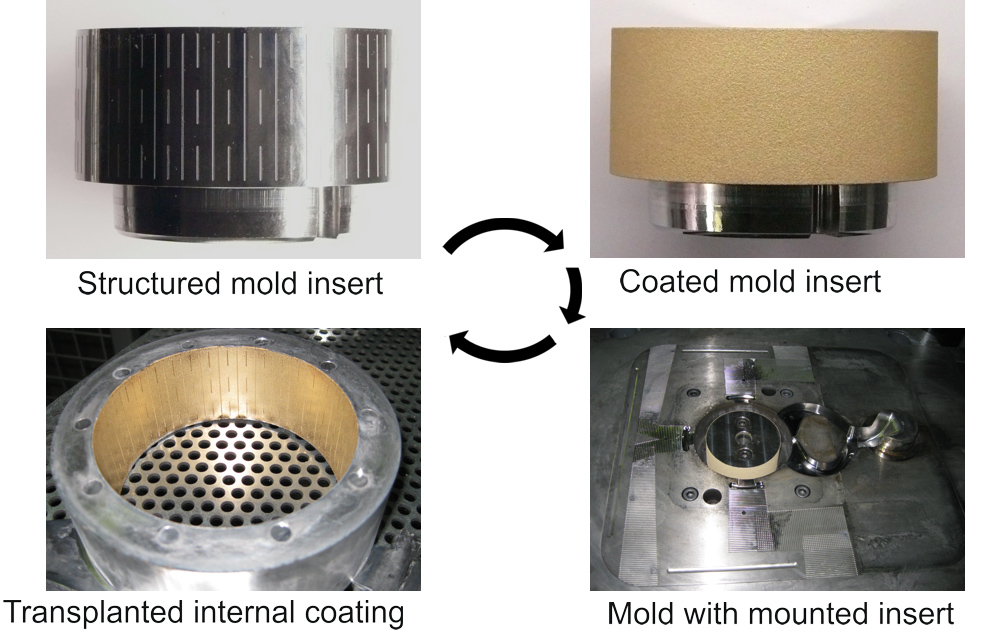

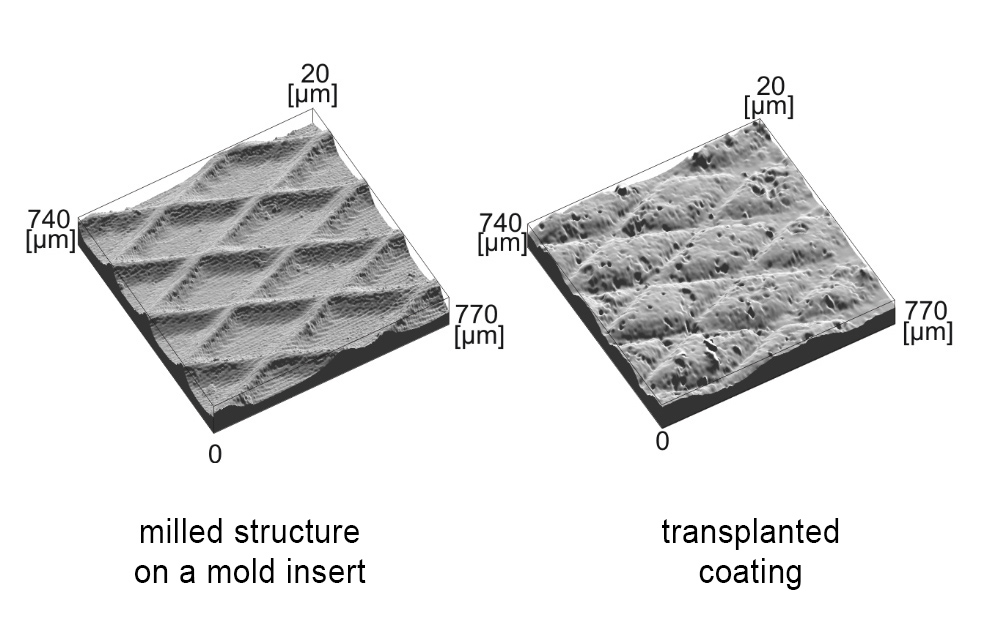

The basic principle of thermal spraying is simple: Coating material is melted and accelerated towards the surface to be coated. With the transplantation method, not the finished component is coated but an insert that is placed into the casting mould. The coating is transplanted from the insert onto the component during the die casting process.

The new method facilitates the transplantation of structured coatings without any refinishing as well as internal coating of very small diameters like boreholes. For internal coating, the insert is coated from the outside, since the coating is formed as a negative.

The only problem is: After transplantation, the insert has to be removed from the component. One option are inserts made of salt which can simply be washed away. Researchers at IW are currently investigating in a research project, whether this is technically feasible.