Dear Readers,

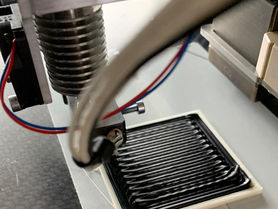

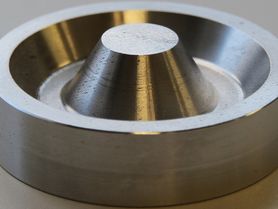

Additive manufacturing is the dominant topic of this issue. ITA and DIK are currently developing the first 3D printer that can process carbon black filled rubber. The IFUM is working on the additive manufacturing of forging dies with integrated cooling. And the LZH and IPH are continuing to support companies in Lower Saxony in the "Niedersachsen ADDITIV" project, which has been extended after three successful years.

However, 3D printing is not the only topic that concerns the Hannover production scientists. The IFW wants to develop a fully automated deburring process together with a software company. The IW is studying the microstructure of nickel-based superalloys used as high-temperature materials in turbines. And the IFA is researching how to configure production planning and control (PPC) holistically.

We hope you enjoy reading, wish you happy holidays and a good start to the New Year. Stay healthy and curious!

Your Editorial Team