The target-oriented and holistic configuration of production planning and control (PPC) poses great challenges for companies. More than 75 percent of the companies surveyed attest their employees only limited or even no knowledge about the effect of control procedures on logistic objectives, such as adherence to delivery dates. This shows PPS-Report 2017/2018, which the Institute for Production Systems and Logistics (IFA) co-authored.

Such studies, but also the analysis of previous (framework) models for describing the processes and interactions within PPC, show that there is a lack of models describing interactions between tasks, procedures and objectives in a structured way.

There are no models available that enable the practitioner to obtain a comprehensive and valid understanding of the complex system of PPC. The research project “Systematic analysis of the effect of production planning and control processes on logistical objectives” is intended to close this gap in the future and to support companies in the target-oriented configuration of PPCs as well as of the entire production system.

Three stages of production configuration

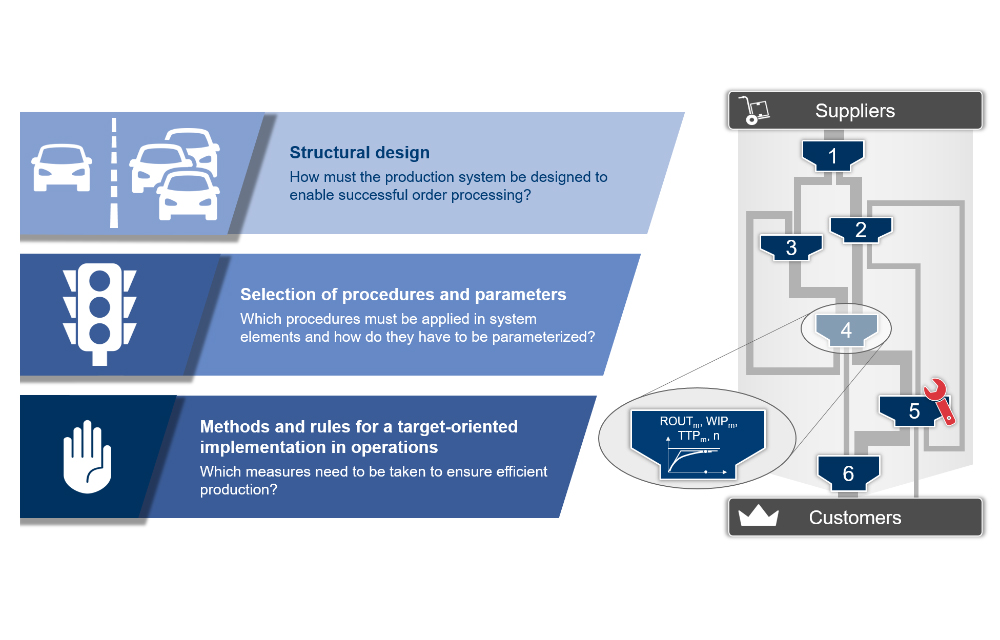

The selection of PPC procedures and parameters is an important step within production configuration, which can easily be divided into three stages (see Figure 2 and Figure 3) and should be aligned with the company’s objectives.

In the first stage, the structural design, a company must fundamentally consider how the production system must be designed to enable successful order processing. This includes decisions such as offering a “fast-lane” for certain products or fundamental decisions regarding the organisational principle of certain production areas.

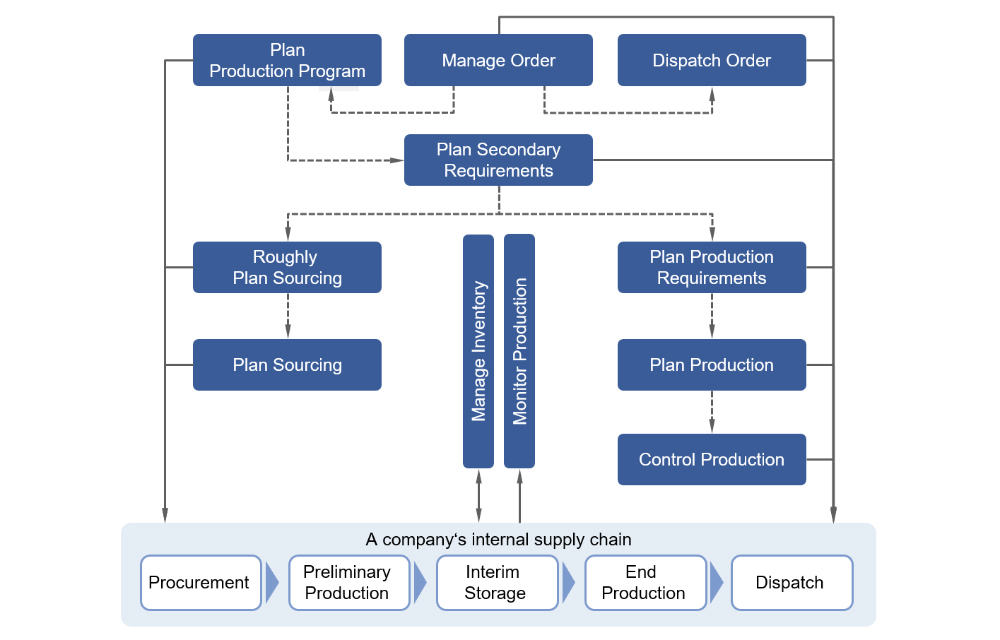

In the second stage, selection of procedures and parameters, it is necessary to derive the PPC configuration – based on the input variables of the first stage and the company objectives. For all PPC tasks, which are described in detail in the Hanoverian Supply Chain Model (HaSupMo) developed by IFA (see figure 4), procedures must be selected and parameters have to be defined in this second stage.

The third step of the production configuration consists in the selection of suitable methods to ensure a target-oriented implementation in the company. This requires a production monitoring system that evaluates all the target, desired, planned and actual values, identifies deviations and makes suggestions for adjustments.

Selection of procedures for PPC tasks

When it comes to selecting procedures and parameters, i.e. the second stage of production configuration, users are faced with an immense number of possible procedures that can be selected for each specific PPC task.

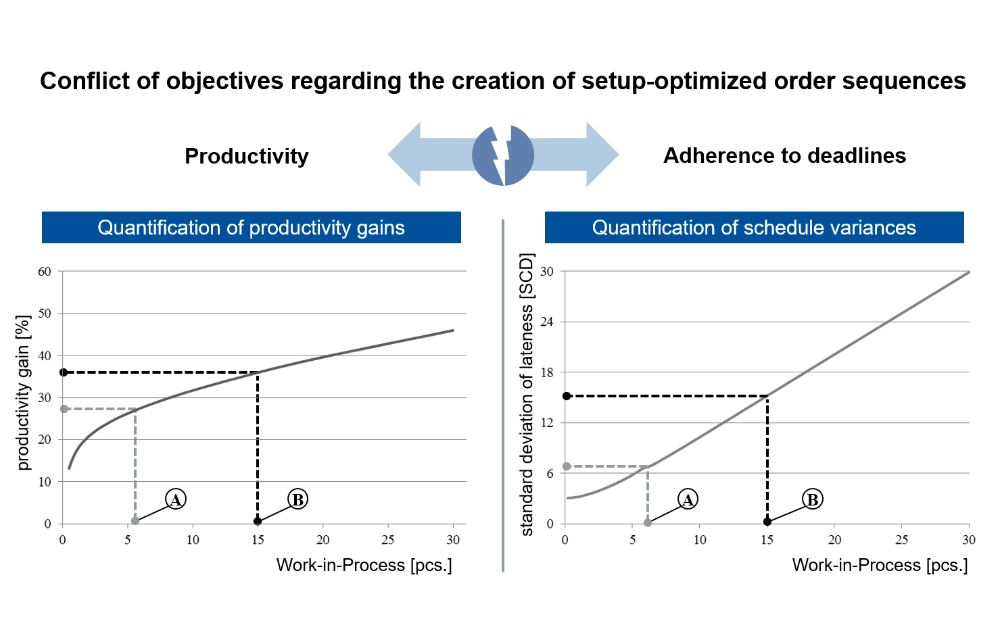

For example, companies must specify the sequence in which jobs from the waiting queue are processed at each work system in production. For this purpose, countless procedures are available – such as set-up-optimised sequencing, sequencing by due dates or first-in-first-out sequencing, to name just a few.

Each of these procedures influences the behaviour of the work system observed in a different way depending on the work-in-process and thus influences the production as a whole. A set-up-optimised sequencing, for example, increases the productivity of the single work systems, but at the same time, causes a degradation of the lateness behaviour (see figure 5).

Knowing the impact – achieving objectives

For a holistic positioning of PPC configuration within the resulting conflicts of objectives, the practical user must be able to already forecast the (inter-)effects of PPC procedures on objectives such as lateness behaviour in the design phase of the system. Only in this way, it is possible to derive, for example, sequence strategies for production areas – or to define measures, which compensate accepted negative effects.

In this respect it is important and indispensable to consider the PPC and the production as a place of added value as a whole and not to carry out partial optimisations for individual PPC tasks or production areas.

Benefits in practice

By providing a uniform description of dependencies and interactions between procedures of production planning and control and the influence of these on logistics objectives, IFA supports companies in configuring their PPC in a holistic and target-oriented manner. For this purpose, IFA uses meshed relationship networks as well as logistic models with whose help the effect of decisions in PPC configuration can be checked and quantified. By embedding the PPC configuration in the stages of the production configuration, IFA is also developing a cross-task approach that shows which decisions companies should scrutinise within system configuration to improve the achievement of objectives – analogous to technical control loops.

With its current research activities, IFA wants to achieve that companies understand better the interactions within PPC as well as between the individual stages of production configuration – and consciously apply the findings in future when making configuration decisions in practice. The results of the research project will be integrated into the Hanoverian Supply Chain Model (www.hasupmo.education) in future.

Acknowledgement

The research project “Systematic analysis of the effect of production planning and control processes on logistical objectives” by the Institute of Production Systems and Logistics (IFA) of Leibniz University Hannover and by the Institute for Product and Process Innovation (PPI) of Leuphana University Lüneburg is funded by the German Research Foundation (DFG) – 434659386.