Belt conveying systems are used for long-range transportation of large quantities of ore and coal. Such large-size conveying systems are installed by splicing individual conveyor belt segments on site (see Fig. 2).

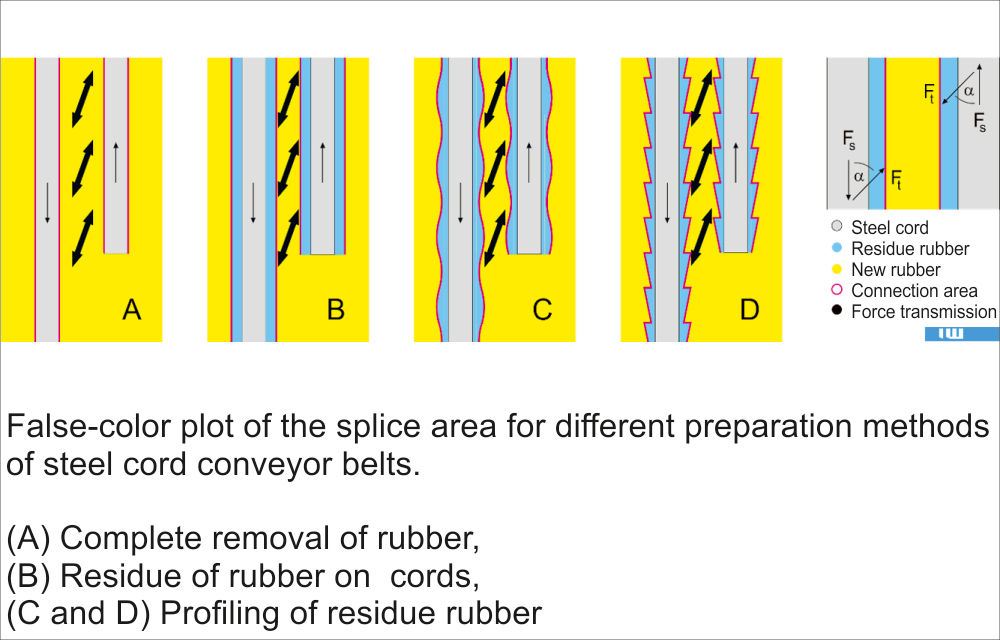

First, the rubber has to be removed on both ends in order to expose the steel cords. Up to now, this is done in several manual steps requiring many technicians (see Fig. 3). The splice quality highly depends on the technicians’ experience. In contrast, an automated approach would guarantee consistently high quality.

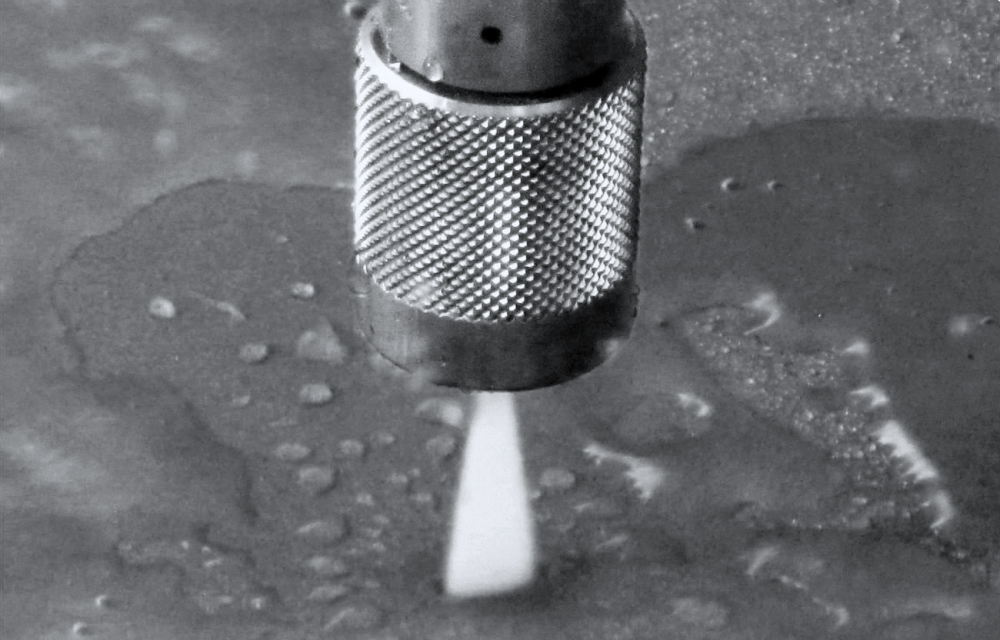

An automated exposure of the steel cords would be possible using water jet technology – which is proved by first preliminary tests done at the Institute of Transportation and Automation Technology (ITA) in collaboration with the Underwater Technology Centre of the Institute of Materials Science (IW). The aim of a new research project is to determine the best process parameters and to increase the strength of conveyor belt splices – for example by profiling the surface areas. (see Fig. 4).