The economic success of small and medium-sized enterprises (SME) in contract manufacturing and contract manufacturing depends largely on how efficiently the preparation of offers and the placing of orders is carried out. Only then can production resources be fully utilized and on-time production be guaranteed. Contracts are usually awarded at short notice and require a great deal of coordination between the contracting parties.

Trading platforms should help to acquire new orders and increase capacity utilization. At the same time, they offer support in the search for suitable companies to outsource individual production steps. But working with traditional trading platforms also involves considerable manual effort.

An innovative assistance system for automated trading of production capacities is designed to reduce the amount of work and enable companies to generate offers automatically. The system is being developed by the Institute of Manufacturing Engineering and Machine Tools (IFW) as part of the project "Assistance system for cross-company trading of production capacities (JobTRADE)".

Optimisation potential in the quotation process

Can we produce the order on our machines? What delivery date and what price can we tell the customer? Feasibility checks, scheduling and calculation are very time-consuming in companies. There is a considerable potential for savings here. According to a study of 110 medium-sized production companies, the procurement of information alone accounts for 30% of non-value-added working time.

This is confirmed by the IFW scientists: In the JobTRADE project they conducted expert interviews with customers of their cooperation partner Fauser AG, a provider of Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES). The weak points in the information flow of the offer process became clear. Missing component specifications, lengthy feedback loops and the distributed knowledge about one’s own manufacturing competencies and capacities can increase the time needed to prepare a quotation from a few hours to over a week.

JobTRADE uses ERP and MES data

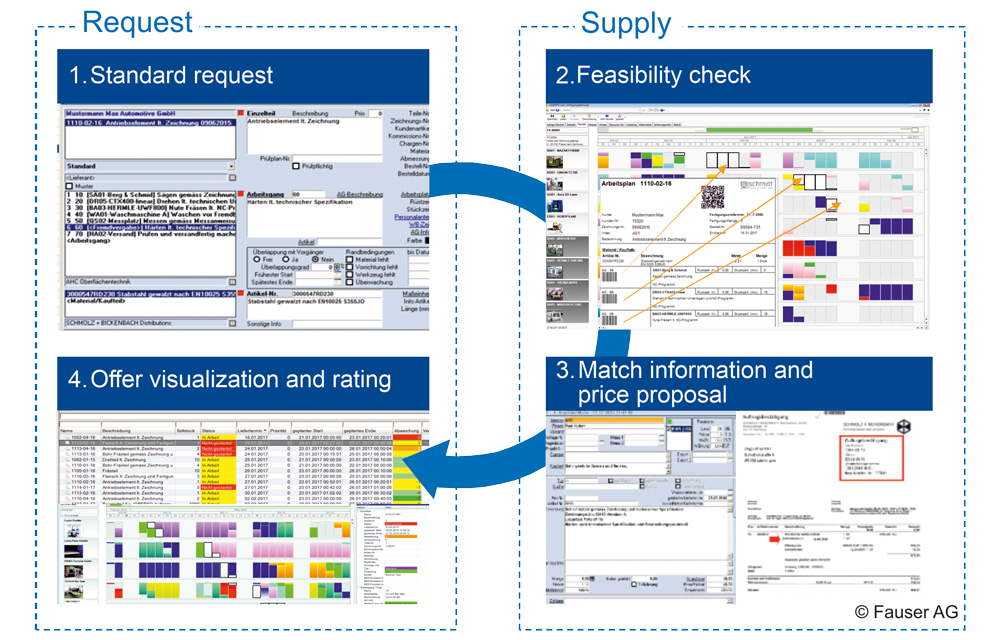

The JobTRADE assistance system aims to reduce non-value-added working time for information retrieval by 30% (see Figure 2). This goal is to be achieved by integrating ERP and MES data. The JobTRADE system thus sets itself apart from trading platforms active on the market.

This first-time link to the internal planning and management systems will enable capacity trading to be automated, starting with the input of order data into a standardized form. Subsequently, the companies in the network that can execute the requested processes are automatically determined. In this process, company competence profiles (CCP) are compared with the order information. If the check is positive, the assistance system triggers the scheduling and price calculation. Finally, all received offers are available to the client in a clear presentation.

Company competence profile

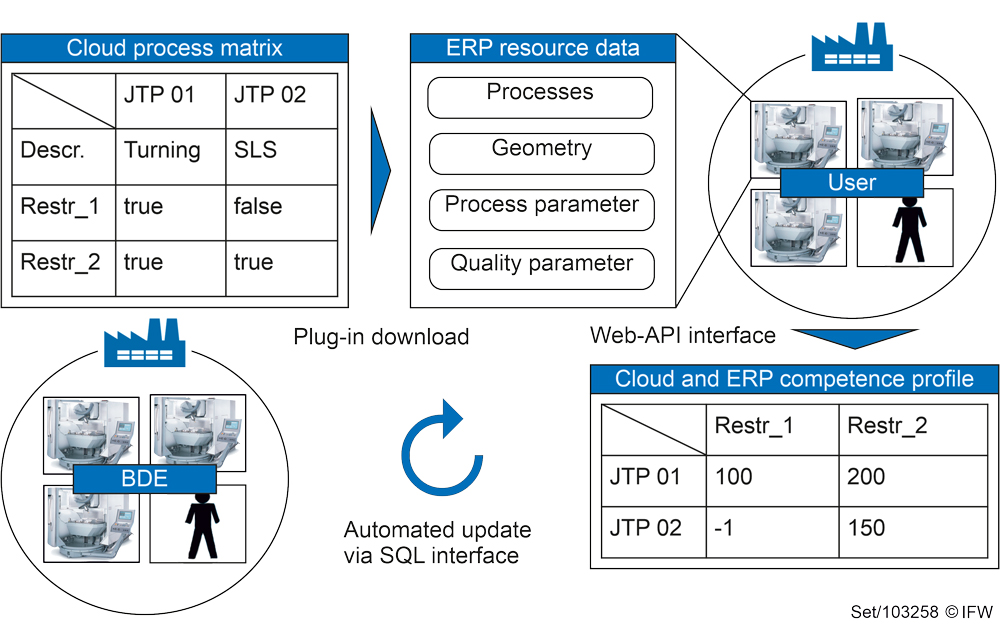

In order to be able to automatically check whether a standardized incoming request for the production of an order is feasible, knowledge of the capabilities of a company’s production resources is required. For this reason, IFW scientists first implemented the company competence profile (CCP) in the JobTRADE research project (see Figure 3).

The purpose of the CCP is to achieve a centrally available representation of competencies. The CCP is based on a restriction-related cloud process matrix just like the standardized request. All defined JobTRADE processes (JTP) are included in this matrix – with broad coverage of CNC manufacturing processes, additive manufacturing and finishing processes. Restrictions are stored for each process, which are decisive for the process capability and are immediately available. This structure is shown in Figure 3. Via a plug-in, the restrictions can be transferred to the resource description of the ERP system.

Expert knowledge

Companies that want to use the JobTRADE system in the future must fill the process-specific data fields once with expert knowledge. On average there are 10 to 15 data fields per process. These include, for example, information on possible component dimensions, travels and tolerances. The restrictions of all production units are then summarized for the respective processes. The presentation is in matrix form, manual adjustments by the user are possible.

The CCP is added to the company’s profile on the JobTRADE online platform via a web API-based interface. In order to ensure that the CCP remains up-to-date in the long term, an SQL connection to the production data acquisition (PDA) is established. This allows autonomous registration that a product has been manufactured in the linked process, which is outside the previous limits. In this case, the company has expanded its competencies and the CCP is extended to the corresponding parameters. Within the scope of the technical feasibility check it can thus be determined directly whether an order is outside the competences. If the restrictions of the CCP are not violated, the limits are then queried at machine level.

The JobTRADE assistance system is intended to enable companies to generate offers automatically. Testing in an industrial environment is planned for 2021.

Funding

The project "Assistance system for automated trading of production capacities" is supported by the European Regional Development Fund.