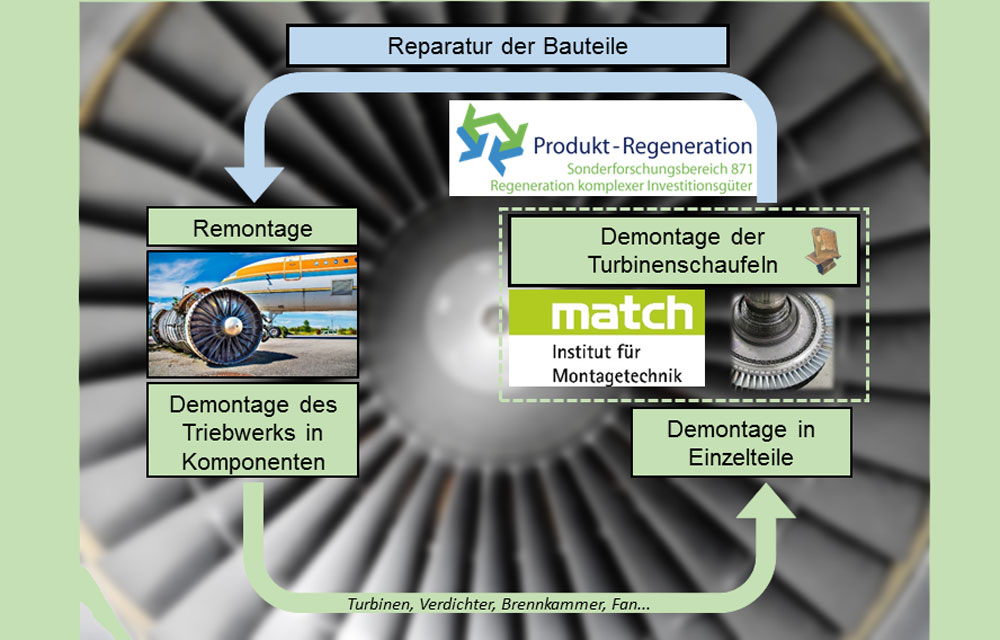

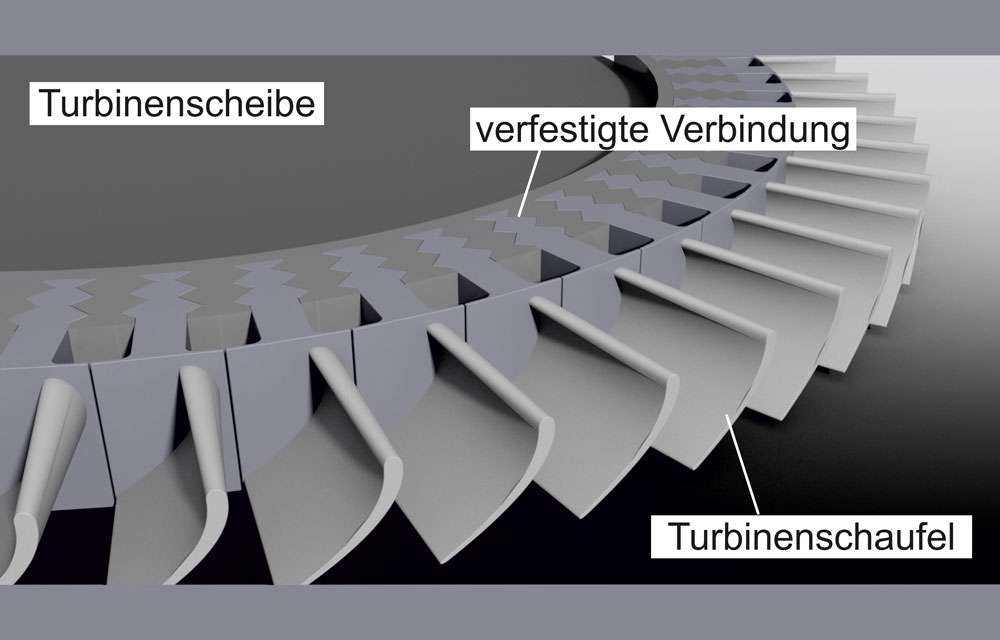

When a product is damaged or has reached the end of its lifetime, it is disassembled into its single components. Damaged parts can be replaced, still functioning parts can be utilised further. However, highly stressed products and even apparently undamaged connections can solidify due to extreme temperatures or forces during operation. For example, solidification occurs in aircraft engines – an application example investigated at the Institute of Assembly Technology (match).

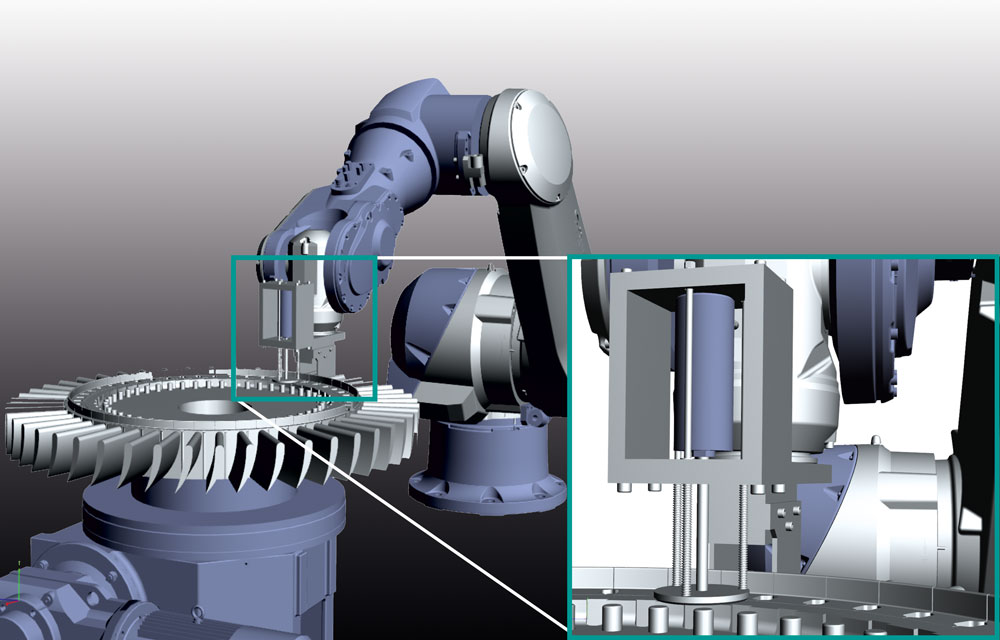

The researchers are presently developing an automated approach for the disassembly of turbine blades. Another aim is to be able to estimate the disassembly forces already in the planning phase. This is achieved by determining the forces required throughout the disassembly process and assigning them to the product history. Research also includes the handling of the disassembly objects. The result: a complete disassembly process. The idea is that robots withdraw the blade and assemble a workpiece carrier.