Hospital systems face similar challenges as factories: historically evolved processes with a strong functional orientation lead to inefficiencies as well as a lack of system efficiency, and old, change-inert building structures prevent adaptation to current and future challenges.

Factory planners speak of flow orientation and transformability when it comes to designing systems that are efficient and fit for the future. In order to transfer these target areas to hospital (construction) planning, the Institute of Production Systems and Logistics (IFA) at Leibniz University Hannover is collaborating with the Institute of Technology and Management in Construction (TMB) at the Karlsruhe Institute of Technology (KIT). As part of the “MedFAP” research project, they are developing factory planning guiding principles for planning flow-oriented hospitals with transformable space, technology and organizational concepts.

Research with practical relevance for hospital (construction) planning

The economic situation of hospitals is precarious. For the treatment of patients, hospitals are not reimbursed for the actual costs incurred, but are paid a fixed flat rate according to diagnosis-related case groups. Consequently, treatment costs must be kept as low as possible, especially since hospitals must generate future investment requirements independently from their revenues. In addition, the turbulent environment in which hospitals operate results in enormous pressure to change, for example as a result of technological progress, demographic change or, most recently, the Covid19 pandemic.

Efficient and cost-saving processes, as well as a system capable of change, are therefore highly relevant for the practice, for basic as well as for maximum care providers. The claim for the research results is therefore that they are valid for all classes of care.

Factories produce – so do hospitals

For the transfer of factory planning approaches to hospitals to be possible, the existence of analogies between the two systems is the basic prerequisite. If the objects of observation of both systems – products and patients – are compared, they supposedly have nothing in common. However, production and treatment are predetermined by superordinate main processes. In addition, a differentiation can be made for both objects of observation: For factories into different product groups, for hospitals into different diagnosis-related case groups. For these groups, a further subdivision into product variants or individual clinical pictures is also possible.

It follows that several production or treatment processes coexist in both systems, resulting in workflows that differ from each other and complex flow relationships. These commonalities allow the working hypothesis that, in simplified terms, not only factories but also hospitals “produce” and that the respective system interrelationships are comparable with each other, so that ultimately factory planning approaches can be transferred to hospital systems.

Guiding principles for flow orientation and transformability

Fundamental to the research approach is the description of the hospital system. In order to ensure the validity of the research results for all hospitals, the first step is a generally valid classification into basic to maximum care providers as well as the definition of system levels and areas and the identification of possible design objects.

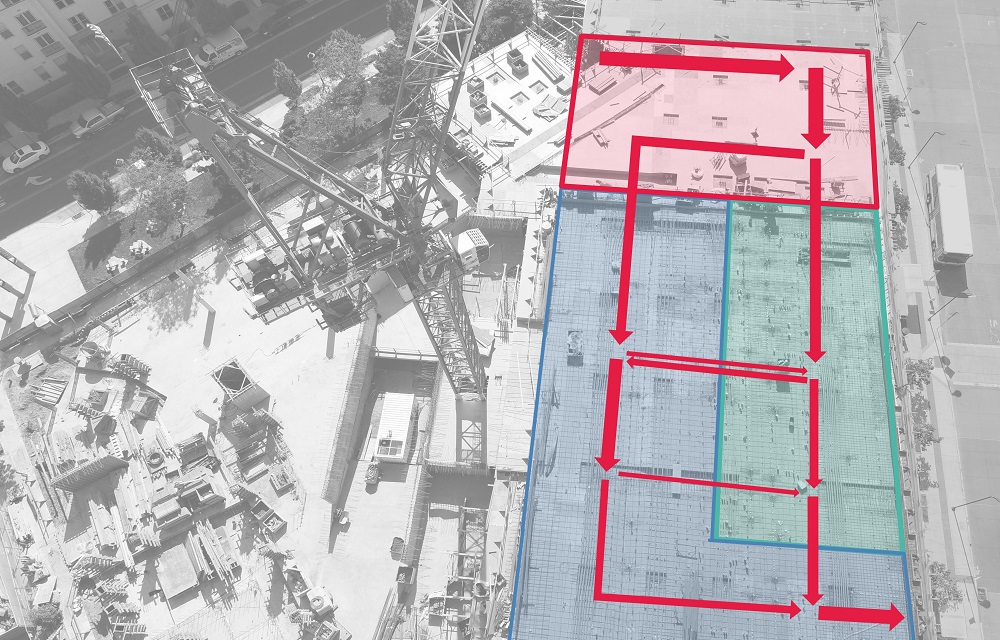

With the help of the previously defined system levels and areas, a holistic process flow model is then developed, from which the guiding principles for the ideal arrangement of hospital areas are subsequently derived, enabling flow orientation in hospitals.

Based on the design objects already identified, a maturity model will then be developed to assess the transformation potential of a hospital, and finally derive guiding principles for transformational concepts in the individual functional areas.

Project support by partners from practice

In order to achieve application-oriented research results, information from practice is necessary to derive guiding principles. On the other hand, these are to be finally evaluated by case studies and workshops. Participation from hospital practice is therefore crucial for the success of the research project. As partners for the research project “MedFAP” different medical universities and further hospitals could be inspired, which promised their support and now follow and accompany the research progress with large interest.