Composite materials such as carbon fiber reinforced plastics (CFRP) are ideal for lightweight construction. As a result, there is great interest in these materials in, for example, the aircraft and automotive construction industries. But the relatively high manufacturing and processing costs for these materials still prevent their widespread use. Automated and easy-to-use laser systems could make composites more attractive to these markets.

Drilling high-quality holes in CFRP is a challenging process. On average, manufacturers drill 34,000 holes in the A350 fuselage section 13/14 alone during the production of an aircraft. Conventional drilling tools wear out quickly. To meet the exceptionally high quality requirements of the aviation industry, manufacturers have to change the drills frequently. But this is time-consuming and costly. If the tools are changed too late, conventional milling and drilling quickly lead to quality defects, such as delamination, high heat input, undesirable indentations on the sidewalls, and dimensional deviations.

Laser instead of drill: flexible and wear-free

In the future, the laser could provide a remedy. This is because laser drilling in composite materials such as CFRP laminates neither causes tool wear nor causes the laminate layers to detach from each other. Heat input can also be reduced to a minimum.

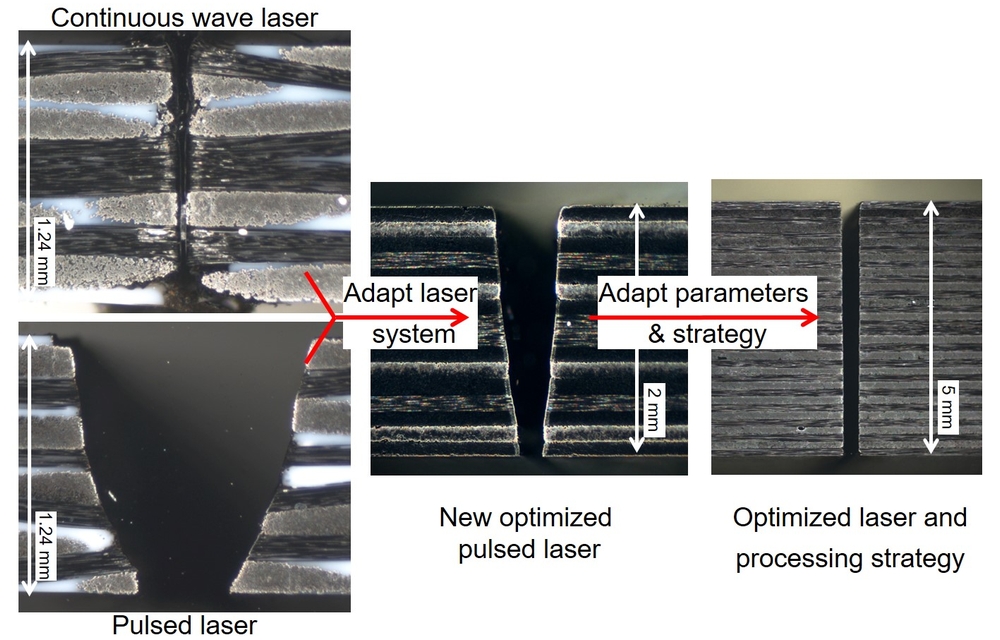

The system technology, laser process, and software were developed by the LZH in the LaBoKomp project with industrial partners and successfully tested on so-called “cargo struts”. These are C-shaped struts made of CFRP that stabilize the cargo hold floor in aircraft, for example. The LaBoKomp system unites the advantages of continuous-wave (cw) and pulsed lasers in a nanosecond-pulsed high-power laser. This laser combines high pulse energies with a high beam quality and a small focus diameter.

Minimal heat input thanks to a multipass strategy

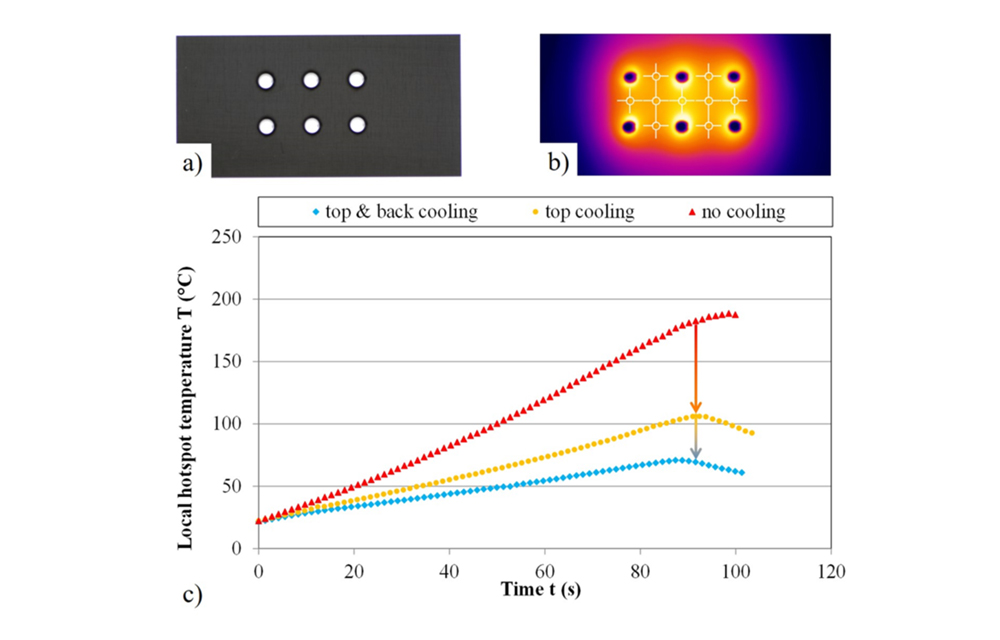

The new laser drilling system prevents thermally induced changes in the plastic material with the so-called multipass strategy. In this process, the laser beam travels several times over the machining contour, removing only a very thin layer of material at a time – with minimal heat input. In addition, integrated nozzles for the supply of cooling gases, such as compressed air, further reduce the thermal load, and an exhaust system discharges process-related fumes and particles.

An integrated thermal camera continuously measures the temperature. It controls the time intervals between passes based on a temperature limit to be set by the system operator. This allows the new laser drilling process to be automated with high process reliability.

Plant operators control and monitor the laser drilling process with specially developed software. With this, they can adjust the process parameters and all system components each time the laser beam passes over them while the process is running. Quality defects such as undesirable tapers or uneven sidewalls can thus be avoided.

Achieving aerospace standards with special machining routines

The project partners developed special machining routines to improve the kerf angle to produce drilled holes without undesirable tapers. If the height of the laser beam’s focal plane is adjusted after a variable number of passes and with optimized process parameters, the laser drilling process produces right-angled kerf joints without a heat-affected zone. In up to 5 mm thick composites, rivet holes can be drilled to meet the customary in the aerospace industry.

Mechanical load tests on components made of CF/epoxy materials yielded values comparable to conventionally drilled specimens. Tests with an overlapping CF/PPS and CF/epoxy composite were successful despite different plastic types and fiber structures. No residues were found in the space between the parts.

The equipment and process are suitable for all CFRP types commonly used in aerospace and laminates with GFRP face sheets and Coppermesh. For 2.4 mm thick composites, the drilling time per hole is only 10 seconds. Conventional methods require about 4 seconds per hole.

Outlook

In the ‘LaBoKomp’ project, the partners succeeded in confirming the fundamental practical suitability of the laser drilling process and the equipment based on industry-related application cases. Follow-up projects will address the need for processes to efficiently produce small holes on large surfaces, such as soundproofing elements in aircraft construction. In addition, the accuracy of counterbores in curved components was still found to be insufficient. Here, too, further investigations into optimized parameters and improved machining routines are desirable.

The aim is to supplement conventional, mechanical drilling processes or to replace them in the long term.