In the course of energy transition, offshore wind turbines play an ever-increasing role. However, repair work done at offshore plants poses a problem: To ensure a life expectancy of 25 years, engineers increasingly use higher-strength steels. The disadvantage: Today’s steels cannot be welded under water when repair is needed.

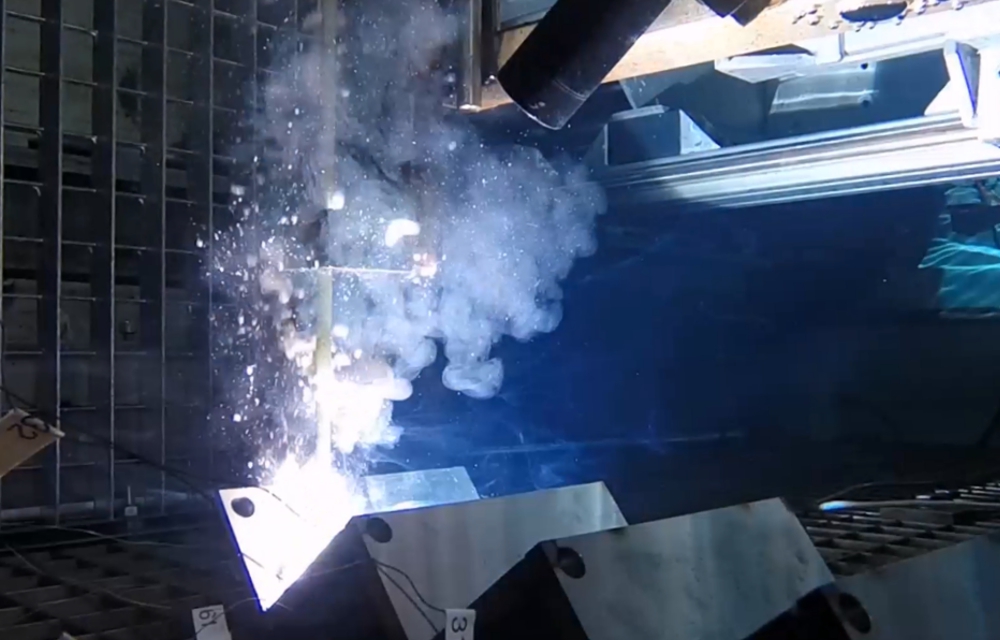

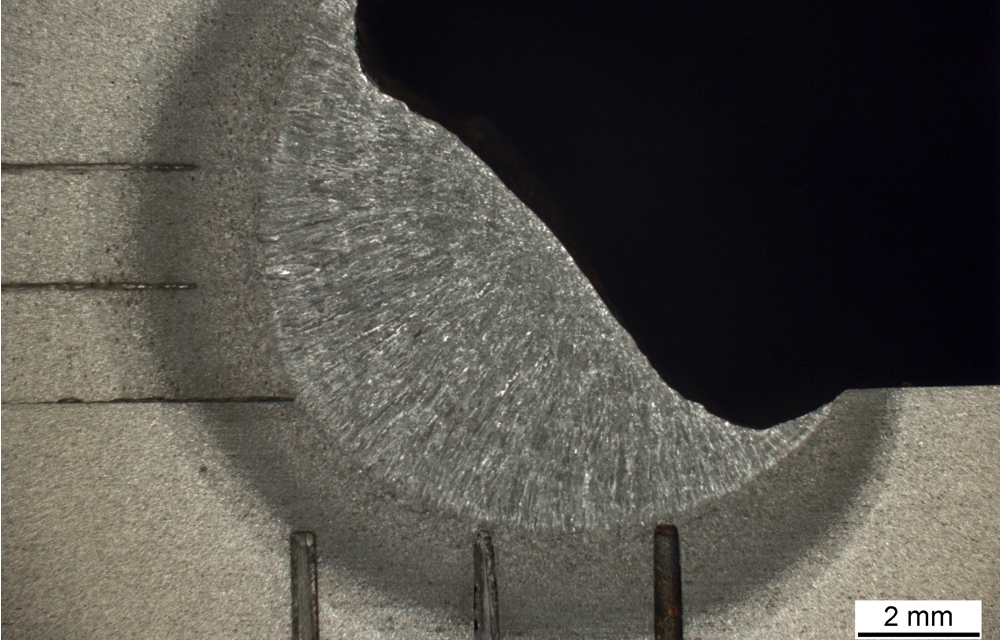

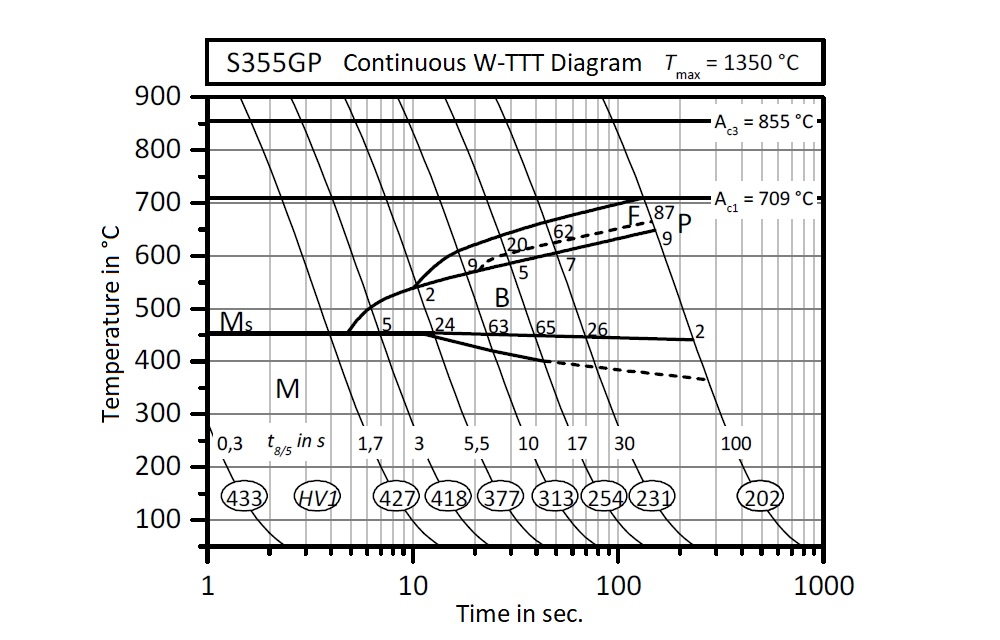

For this reason, the researchers’ aim is to provide the fundamentals for simulating the complex conditions of materials during wet underwater welding numerically. Research at IW comprises welding tests as well as quenching tests carried out under water after a heat treatment, in order to characterize heat transfer and phase transformation kinematics of wet welding processes. At the Chair of Materials Science of Universität Rostock, the results are used to create an FE model – a software solution for the benefit of designers in on- and offshore industry.